Chapter 4 – Maintenance

TestEquity FS Series Ovens Page 4-3

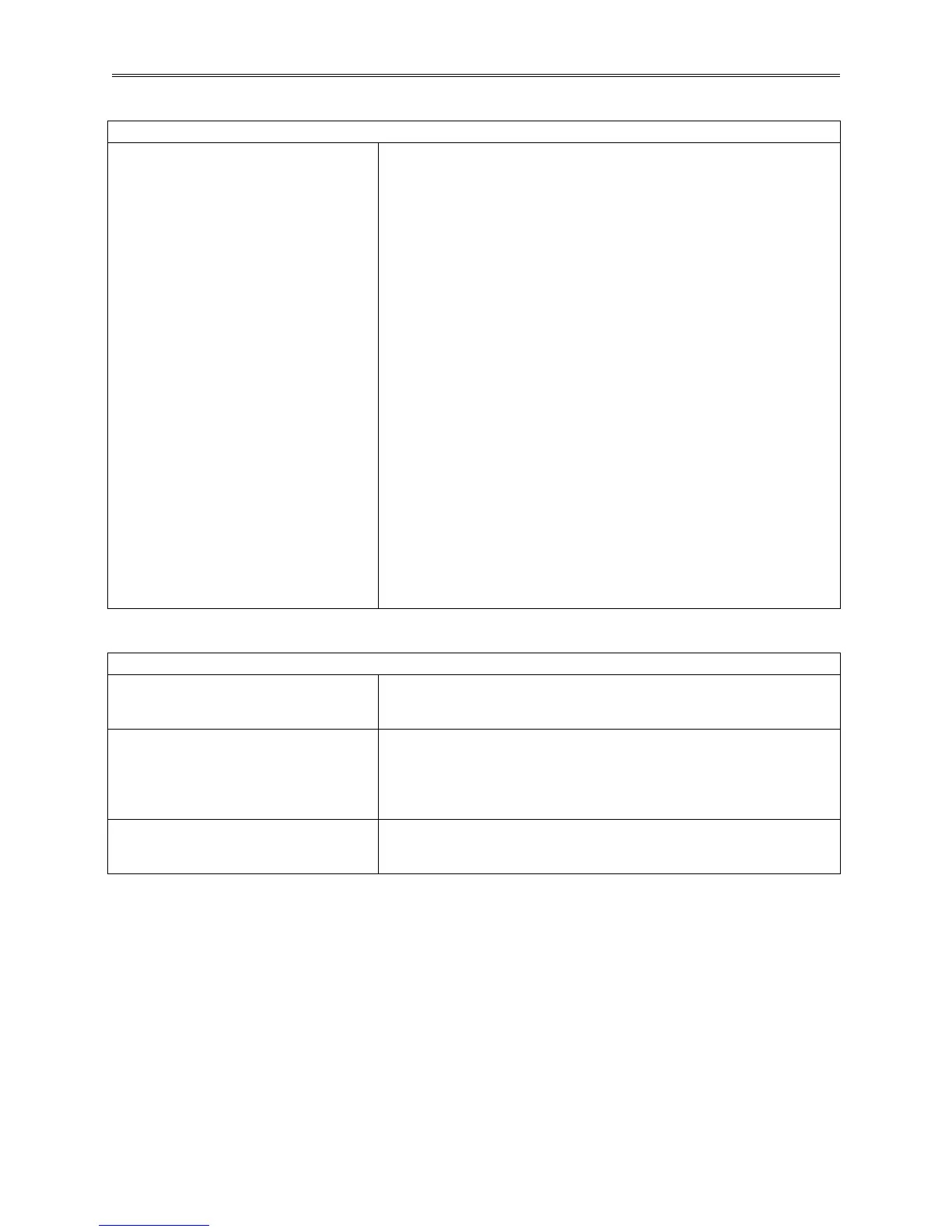

Indicated chamber temperature

unstable

1. ±0.1°C variation is normal.

2. Make sure fan is working. Verify movement of air in chamber.

3. Room temperature is radically changing – either door opening or

room airflow from heaters or air conditioning. Stabilize the ambient

conditions.

4. This may happen if exhaust stack is 100% open or if power exhaust

is cycling – adjust stack to at least ¼ closed.

5. Sensor miss-located, damaged or wires may be damaged. Check

mounts for control and overtemperature sensors, then trace wires or

tubing between sensors and controls.

6. Defective temperature controller. Call Customer Service.

7. OVERTEMP PROTECTION set too low. Be sure that

OVERTEMP PROTECTION is set more than 5 degrees over

temperature set point; check if OVERTEMPERATURE light is on

continuously; turn OVERTEMP PROTECTION knob completely

clockwise to see if problem solved then follow operating

instructions for correct setting.

8. Electrical noise. Remove nearby sources of RFI including motors,

arcing relays or radio transmitters

9. Bad connection on temperature sensor or faulty sensor. Check

connectors for continuity and mechanical soundness while watching

display for erratic behavior; check sensor and wiring for mechanical

damage.

10. Bad connections or faulty solid state relay. Check connectors for

mechanical soundness and look for corrosion around terminals or

signs of arcing or other visible deterioration.

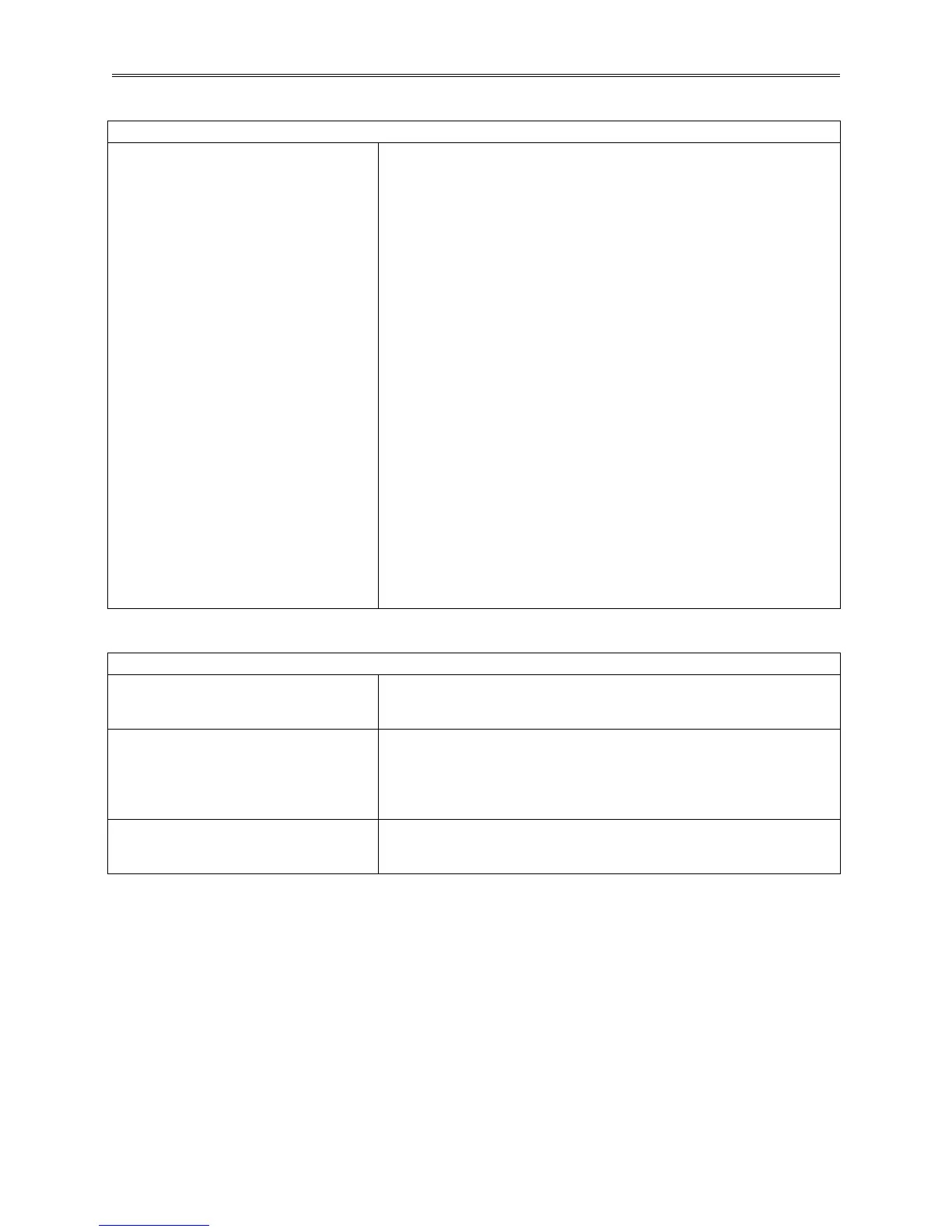

1. If shaft spins freely: check connections to motor and check voltage

to motor.

2. If shaft rubs or is frozen, relieve binding and retest.

1. If noise is from the motor, tap the top of motor shaft with ball peen

hammer.

2. If the sound gets worse, tap the other end of the shaft – avoiding

touching the blower wheel.

3. If there is no change, call Customer Service.

1. Adjust hinge blocks, chamber latch bracket or twist the door.

2. Confirm that unit has not been damaged and body is not square.

3. Check physical condition of gasket for tears or punctures.

Loading...

Loading...