Chapter 4 – Maintenance

Page 4-2 TestEquity FS Series Ovens

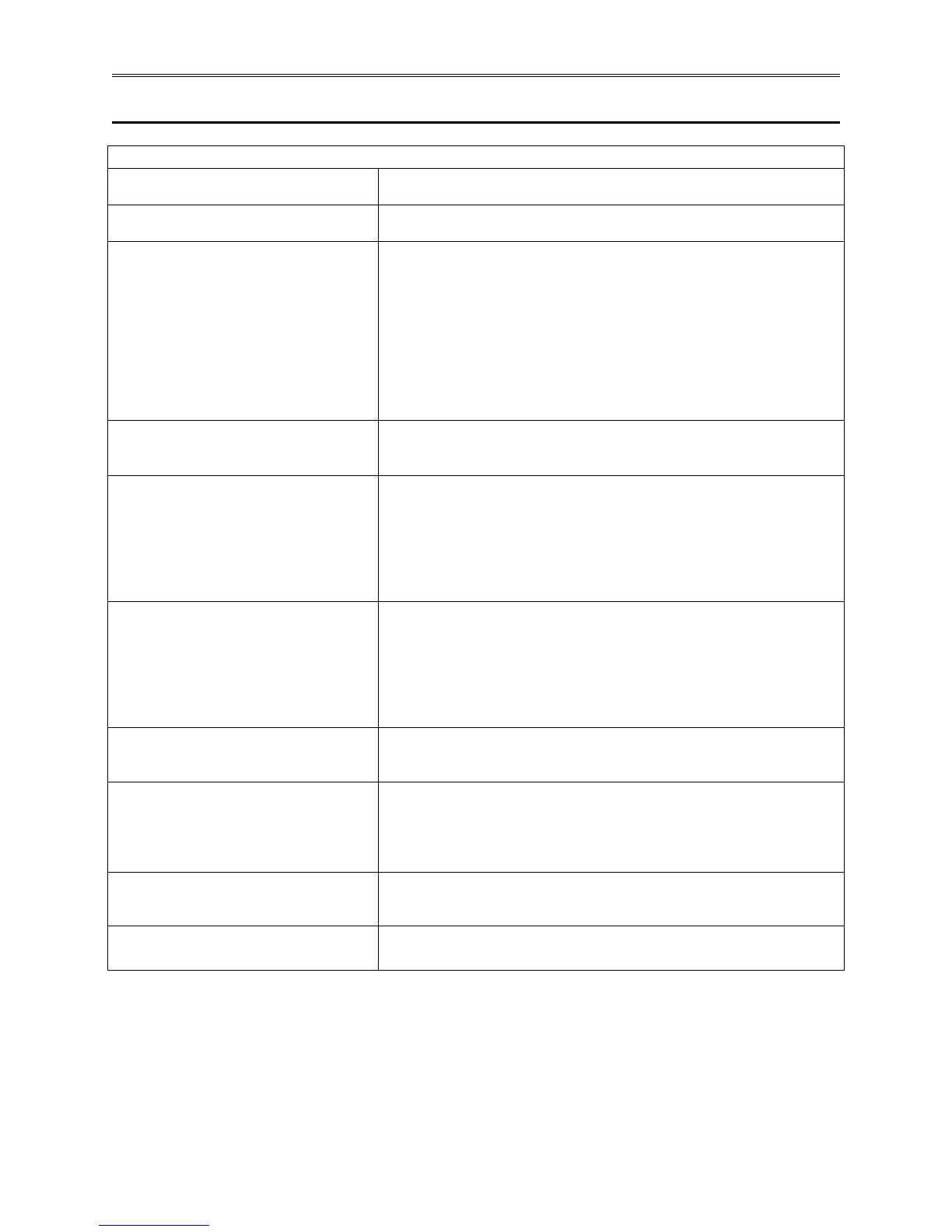

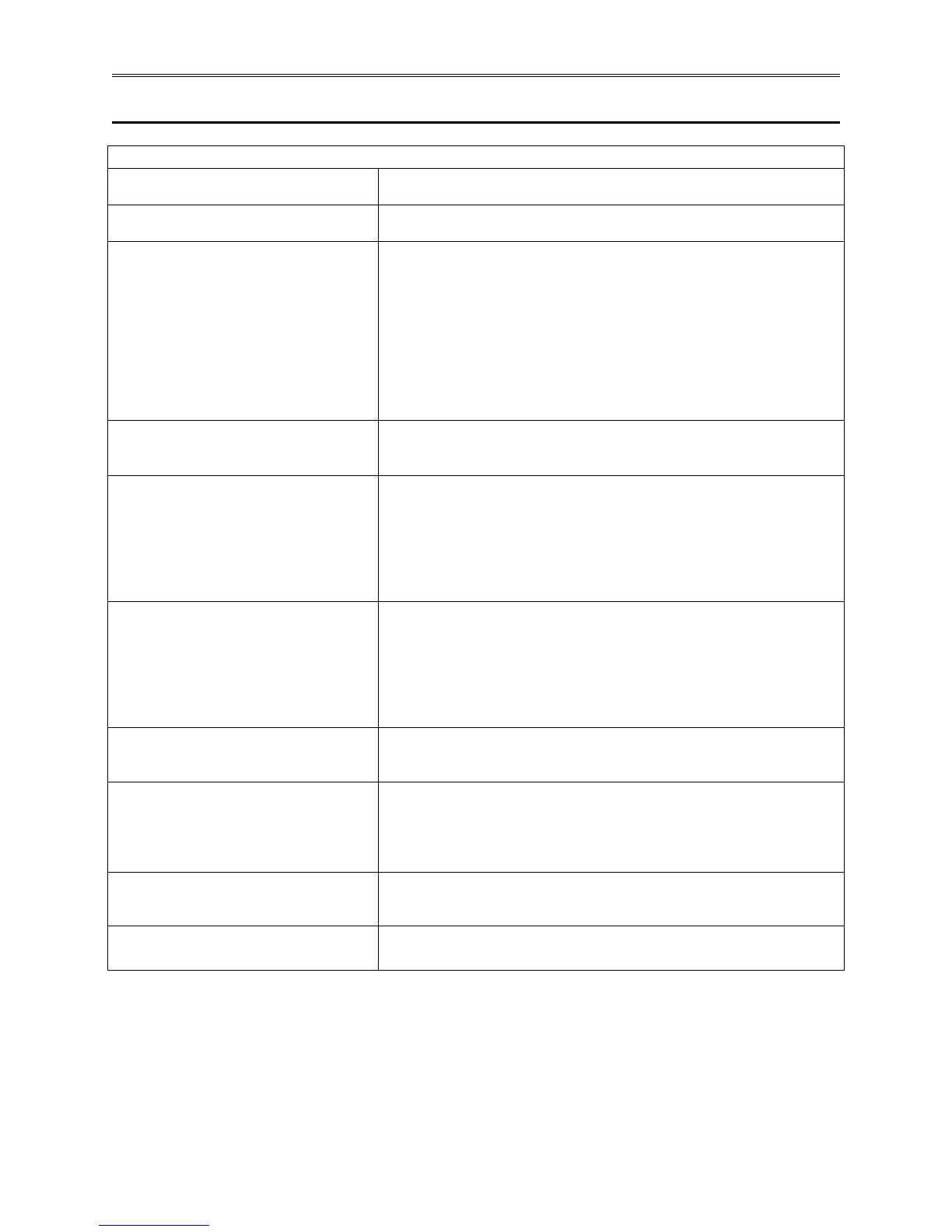

Troubleshooting Guide

1. Controller set point is too high.

2. Controller failed on – call Customer Service.

Display reads “HI” or “400”+.

1. Probe is unplugged, is broken or wire to sensor is broken – trace

wire from display to probe.

1. OVERTEMP PROTECTION set too low.

2. TEMPERATURE controller set too low.

3. Unit needs time to recover from door opening – wait for display to

stop changing.

4. Unit not recovered from power failure or being turned off – ovens

will need several hours to warm up and stabilize.

5. Element failure – compare current draw to data plate.

6. Temperature controller failure – call Customer Service.

7. OVERTEMP PROTECTION failure – confirm with front panel

lights that safety thermostat is operating correctly.

1. Bad probe or disconnected – call Customer Service.

2. If ambient temperature is lower than range of unit – compare set

points and ambient temperature to rated specifications.

Oven will not heat over a

temperature that is below set point

1. Confirm that fan is moving and that amperage and voltage match

data plate – check for air movement in chamber.

2. Confirm that set point is set high enough – turn OVERTEMP

PROTECTION all the way clockwise and see if

OVERTEMPERAURE light comes on.

3. Check connections to sensor.

4. Check calibration using a calibrated instrument.

Unit will not heat up at all

1. Check amperage – amperage should be virtually at maximum rated

(data plate) amperage.

2. Do all controller functions work?

3. Is the Safety Thermostat set high enough? F

or diagnostics, should be

fully clockwise with the OTP light never on.

4. Has the fuse/circuit breaker blown?

5. Has timer turned unit off?

Will not maintain set point

1. Assure that set point is at least 10 degrees over ambient.

2. See if ambient is fluctuating; check for adjacent open doors or

HVAC duct openings – stabilize ambient conditions.

thermometer don’t match

1. Calibration error – Controller needs re-calibration.

2. Temperature sensor failure – call Customer Service.

3. Controller failure – call Customer Service.

4. Allow at least two hours to stabilize.

5. Verify that reference thermometer is certified.

Calibrated at one temperature, but

not at another

1. This can be a normal condition when operating temperature varies

widely. For maximum accuracy, calibration should be done at or as

close to the set point temperature.

Can’t adjust set points or

calibration

1. Turn entire unit off and on to reset.

2. If repeatedly happens, call Customer Service.

Loading...

Loading...