16

HYDRO

MIDSIZE

1

2

1

2

3

3

4

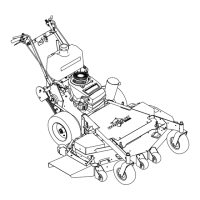

GREASE FITTINGS

Every 50 Working Hours

Lubricate the following points

with grease:

1. Caster wheel pivots—2 points

2. Caster wheel bearings(on

wheel rim)—2 points

3. Deck idler pivot bearings:-2

points

4. Hydro belt tensioner: Located

under engine deck

NOTE, SPINDLES: The

spindles on these machines

use a superior sealed bearing

which does not require

relubrication.

ENGINE

AFTER THE FIRST 5 WORKING HOURS

While the engine is warm, remove the drain cap or

plug and drain the crankcase (drain cap shown at A for

Kohler 20 hp below). Clean and replace the plug.

Change oil filter. Fill the crankcase with fresh oil to the

full mark.

DAILY

• Remove the dip stick and check that the level

reaches the full mark.

• See engine manual for proper oil viscosity and

grade.

• If necessary, top off with fresh oil. To obtain the

correct oil level, the machine must be level.

• DO NOT OVER FILL!

NOTES:

• See engine manual for oil and filter change intervals

after the break in period.

• See engine manual for specifications.

LUBRICATION

Loading...

Loading...