GASOLINE UTILITY VEHICLES

Page 24

Owner’s Manual and Service Guide

Read all of manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notes, Cautions and Warnings

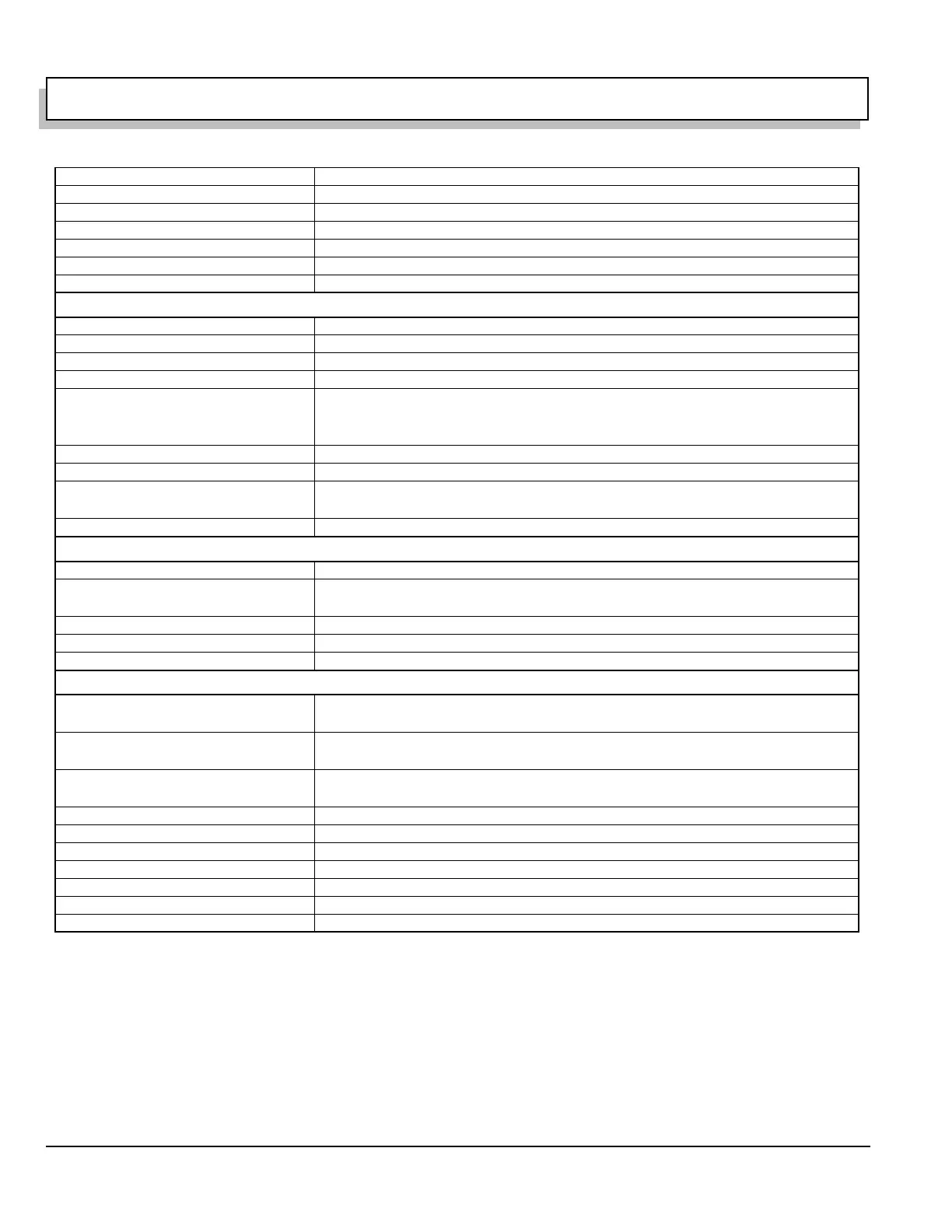

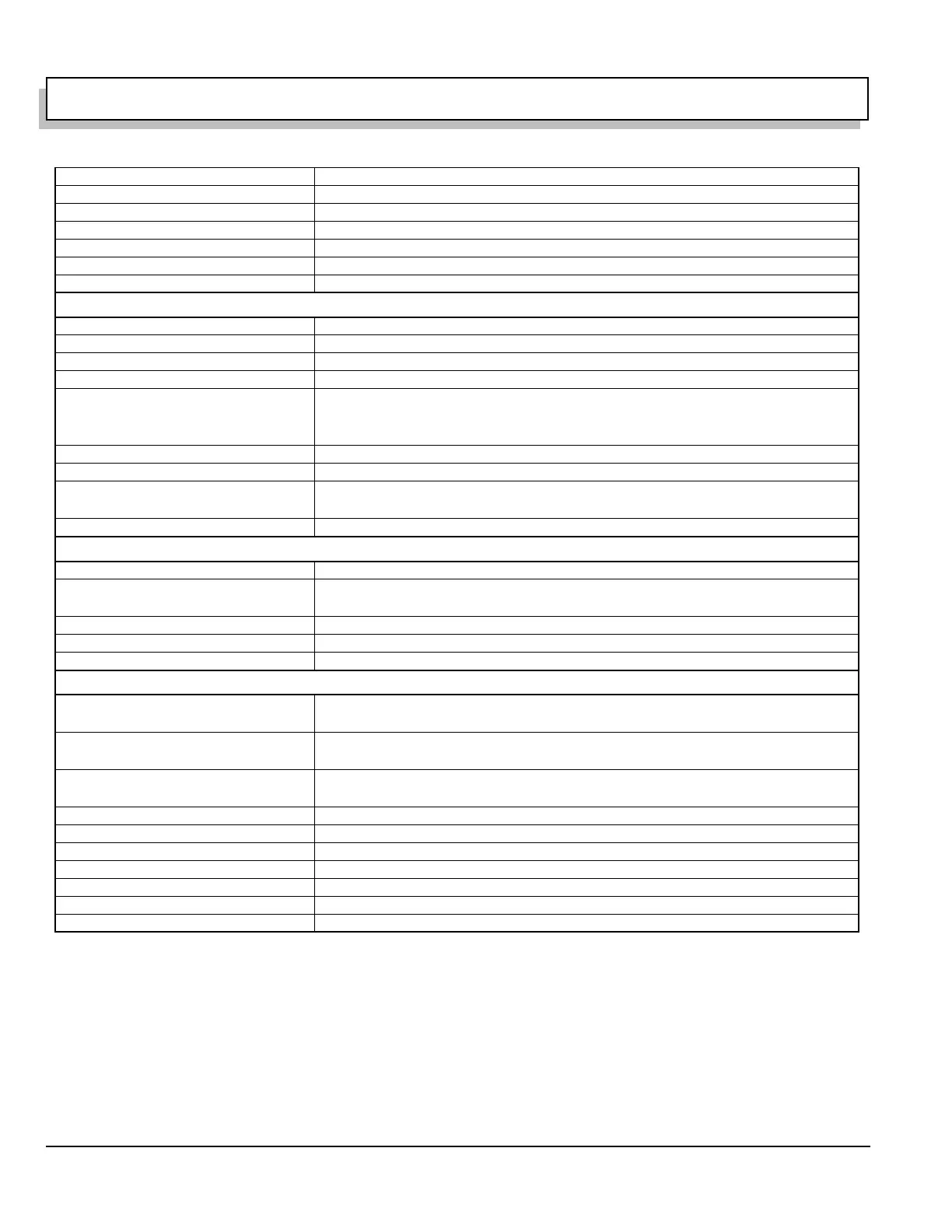

DIRECTION SELECTOR ✓ Check attachment, adjust as required

ENGINE ✓ Check for unusual noise, vibration, acceleration, oil leaks

STARTER/GENERATOR BELT ✓ Check for tension, wear, cracks

COOLING FAN ✓ Check for build-up of foreign matter inside blower housing and fins, clean if required

STEERING ASSEMBLY ✓ Check for abnormal play, tightness of all hardware

TIE RODS/LINKAGES ✓ Check for excessive play, bent components or loose connections

REAR AXLE ✓ Check for leakage, add SAE 30 oil as required

QUARTERLY - 50 HOURS (includes items listed in previous tables & the following)

FRONT AXLE ✓ Check for damage to axle and loose or missing hardware

FRONT SHOCK ABSORBERS ✓ Check for oil leakage and loose fasteners

FRONT SPRINGS ✓ Check for loose hardware, cracks at attachments

FRONT WHEEL ALIGNMENT ✓ Check for unusual tire wear, align if required

PARKING (PARK) BRAKE

✓ Check for bent/binding linkage rod

✓ Check for damage or wear to latch arm or catch bracket

♦ Lubricate, use light oil. DO NOT LUBRICATE CABLES OR BRAKE LATCH

REAR SHOCK ABSORBERS ✓ Check for oil leakage, loose mounting hardware

ENGINE ELECTRICAL SYSTEM ✓ Check coil/spark plug wires for cracks/loose connections

FUEL SYSTEM

✓ Check for leaks at tank, cap, lines, filters, pump, carburetor

✓ Check fuel lines for cracks/deterioration

THROTTLE/GOVERNOR LINKAGE ✓ Check operation and governed speed

SEMI-ANNUAL - 125 HOURS (includes items listed in previous tables & the following)

DIRECTION SELECTOR ✓ Check for wear and smooth movement (lubricate shaft with light oil if required)

KING PINS

✓ Check for excessive play and tightness of retaining nuts

♦ Lubricate, use wheel bearing grease

STEERING ASSEMBLY ♦ Lubricate linkage, use wheel bearing grease

REAR AXLE ✓ Check for unusual noise and mounting hardware

AIR CLEANER ✓ Check filter element, clean/replace as required

ANNUAL - 250-300 HOURS (includes items listed in previous tables & the following)

FRONT WHEEL BEARINGS

♦ Adjust, see Technician’s Repair and Service Manual

♦ Pack, use wheel bearing grease

REAR AXLE

✓ Check lubricant, if oil seepage is evident, add lubricant (SAE 30 oil) as required

▲ Replace lubricant after 5 years

SERVICE BRAKES

♦ Clean and adjust per Technician’s Repair and Service Manual

✓ Check brake shoe linings, wear limit .06" (1.5 mm)

ENGINE OIL ▲ Replace, DO NOT OVERFILL, with SAE 10W-30 or 10W-40, SF, SG, CC oil

FUEL FILTER ✓ Check for dirt buildup

OIL FILTER ♦ Clean in solvent (at oil change), replace ‘O’ ring if required

SPARK PLUGS ♦ Gap .028 - .030 in. (.71 - .76 mm), replace if required

MUFFLER/EXHAUST ✓ Check mounting hardware; check for leaks at head and muffler gaskets

VALVES ✓ Check cold at cam (intake/exhaust), adjust as required

TIMING BELT ✓ Check tension, and for signs of wear/damage, replace if worn or damaged

Fig. 43 Periodic Service Schedule

Loading...

Loading...