EX-TRAFIRE

®

100SD

Operator Manual, Revision T-54-38

Hand torch cutting technique

Avoid unnecessary firing of the torch, each firing of the torch reduces the lifetime of the electrode

and nozzle�

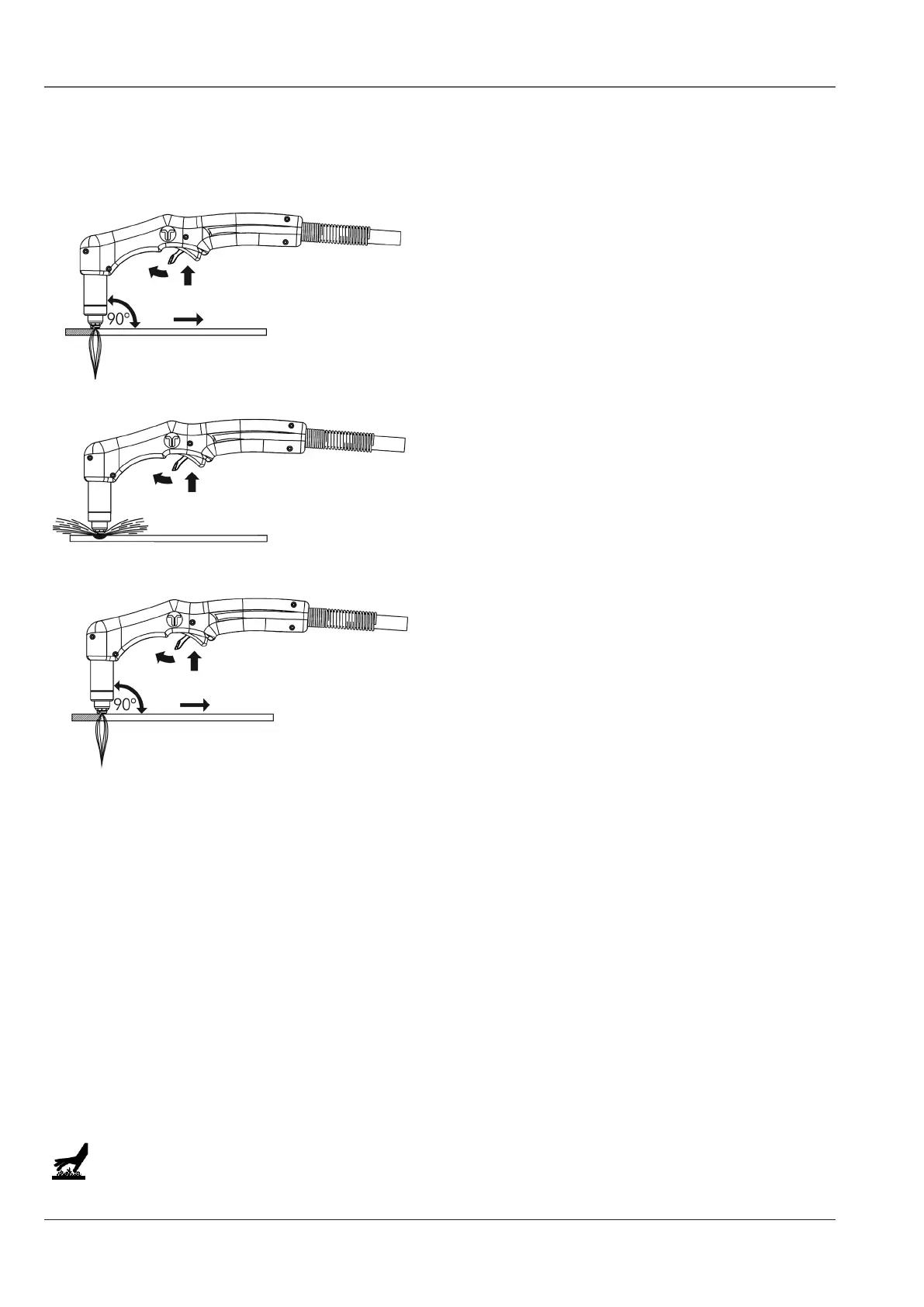

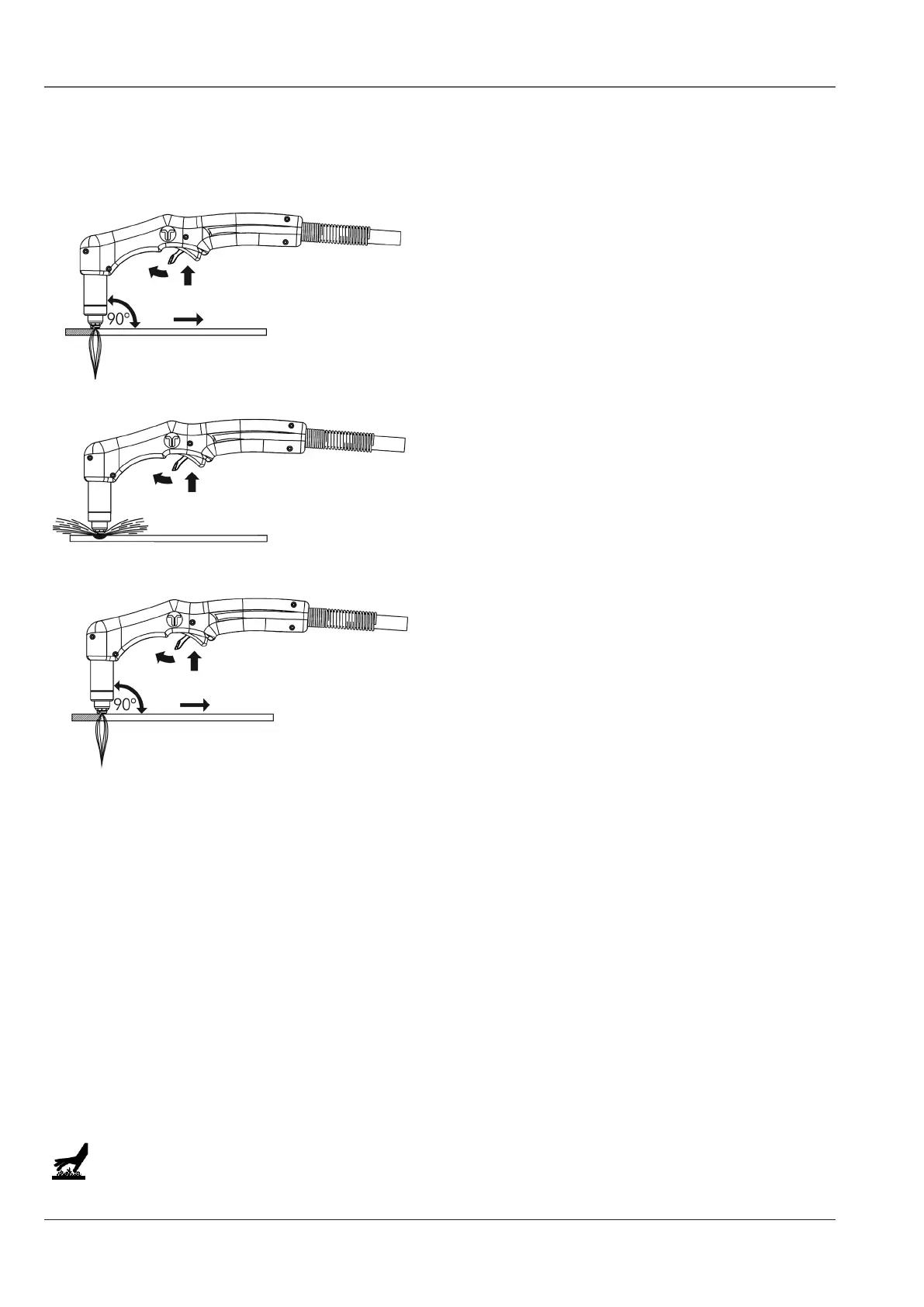

Shielded consumables� Make light contact between the shield and the workpiece, pull the torch

at a steady travel speed�

• Pulling the torch gives better control compared to pushing�

• For cutting thin material, reduce the amperage to the optimum to achieve the highest cut

quality�

• For straight line/bevel cutting, use a straight edge as a guide� To cut circles, use a template or

a circle cutting attachment�

• Gas Post flow – After the torch trigger is released, the gas will continue to flow up to 100

seconds (according to adjusted cutting current and used power supply) to cool the torch and

consumables�

Note: The torch will be ready to restart by depressing the torch trigger during the post flow period�

To stop the post flow, depress the torch trigger quickly and release�

DANGER! Consumables can remain hot after the post-flow period�

When cutting, ensure the arc spray exits

the underside of the workpiece�

Incomplete severance is indicated by an upward

arc spray� This can be caused by the following:

• Excessive travel speed

• Incorrect power settings

• Incorrect gas pressure settings

• Worn/damaged consumables

• or by combination of any of the above

Hold the torch vertically and watch the arc while

cutting along the line�

Direction of cut

Direction of cut

Loading...

Loading...