Disassembly and Reassembly

(Bev.

7, 12l01)

Repair

NOTE: Ualve plates

musr scal co,npletelr o. thc comprcs-

sor win lose capacitJ.

L

lnspecl the cage. ring valve. valve spring.

and relain€r

tbr

wear

or damage.

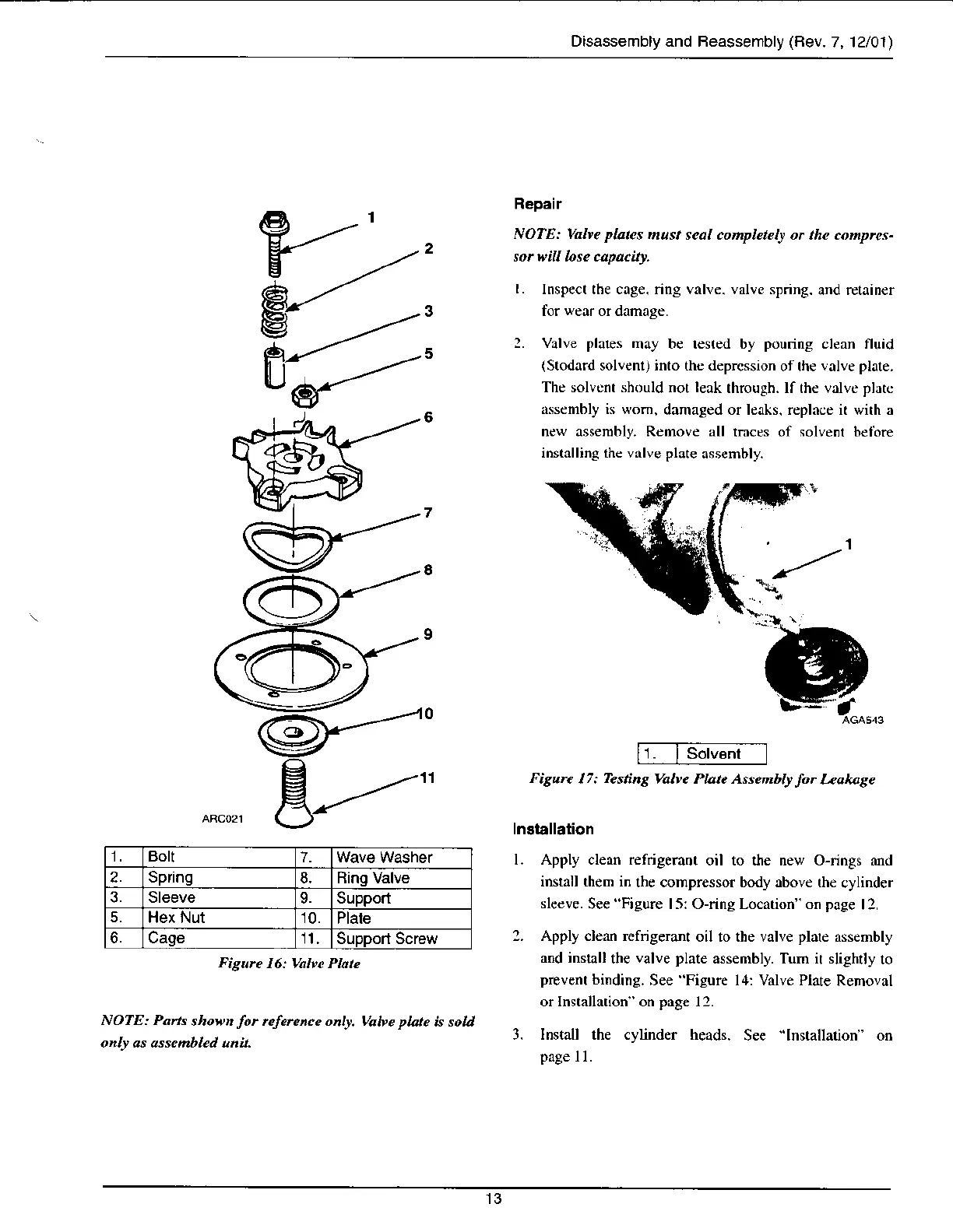

2. Valve plales

may be lested by

pourinc

clean fluid

(Stodard

solven, inlo thc deprcssion

ofthe

valve plale.

The solvcnt should not leak

throuSh. lf the valve

plnte

assembly is wom,

damaged or leaks. replnce it wirh a

new assembly. Rcmove all

lraces of

solvenl

betbre

inshlling the valv€ plate

assembly.

1.

I

Solvent

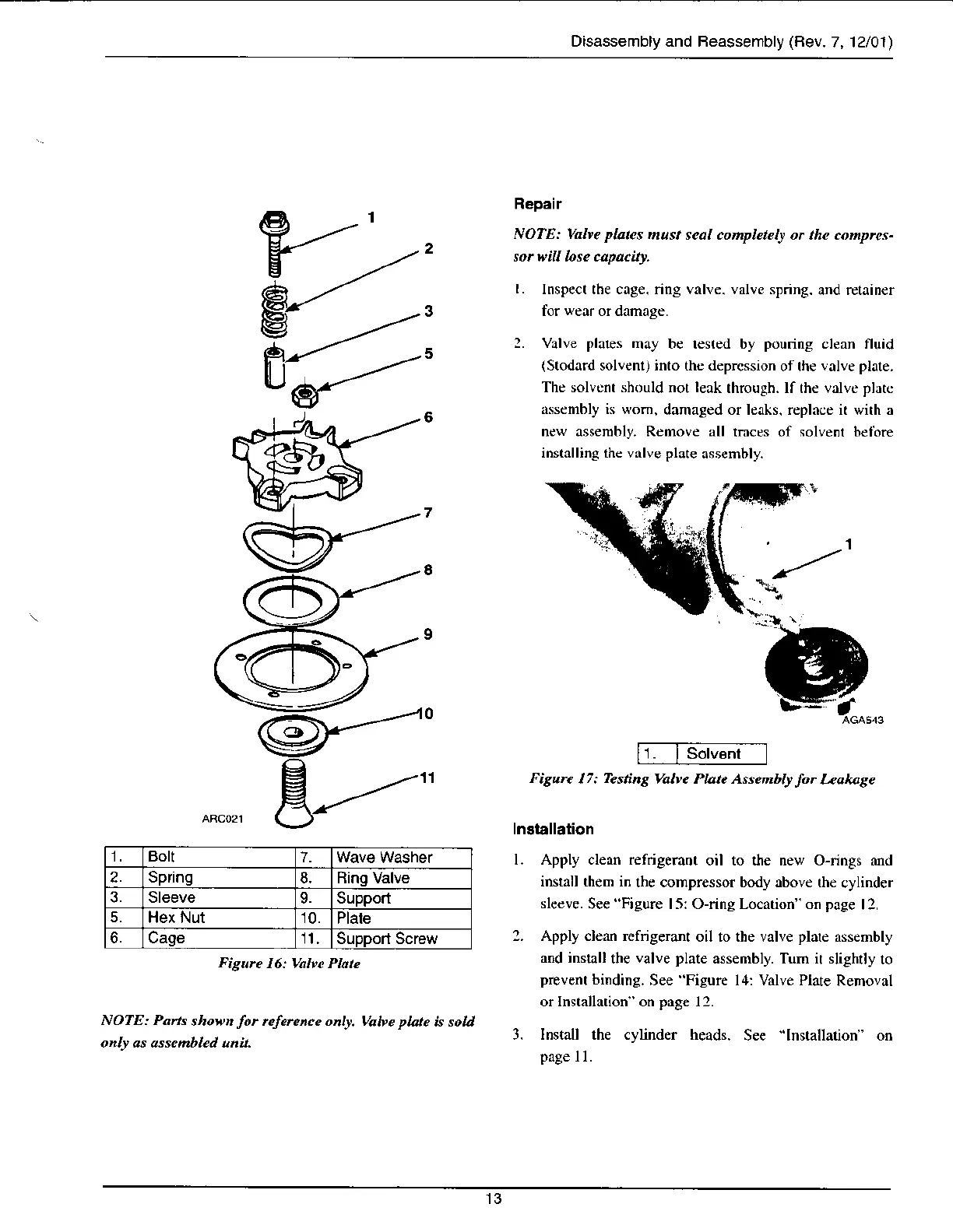

1 Bolt

7.

2. Spring

8. Rino Valve

3. Sleeve

9. Support

5.

Hex Nut 10.

Plate

6. Cage

']l

Supporl Screw

Figure

16: Uabc Plate

Figurc

17:

Testing

Ualve Platc Assenblf

fo.

Iaohage

Inatallalion

l. Apply clean refrigemot

oil to the new O-rings and

inst,tll them in

the compressor body above rhe

cylinder

slccve.

See

"Figure

15: O-ring Location" on page

12.

2. Apply clenn rcftgeranl

oil to the valve

plare

assembly

and install

the

valve plate

assembly. Tum it sliShlly

10

prevent binding.

See

'Figure

14: Valve Plat€

Rernoval

or Installarion" on

page

12.

3. Install the cylinder heads.

See

"lnstallation

on

page

I l.

NOTE: Pans

shown

lot

nfeftnce only, Valve plate

is solt

only as assenbled unit.

Loading...

Loading...