Unloader Head

Operation

During normalopendoD.

the unlonder hcrd

aUows

refriger-

ant to

pass

from

the discharge valvc pla(es

through the

check

valve

located in

the head. Thc solenoid valve

is de-

energizcd in

this

position.

Discharge pressure passes

fronr

Porl A

through the solenoid valle

lo rhe cenrer

porl.

Pon

''C",

$hich forces

the unlonder pisron

down.rnd seals up

rhe

discharge hole ro thc suction

cavily.

Dunng

the unload opcration,

the unloadcr solcnoid

is ener-

gized.

thc prcssure passes

frcm Pon

B" 10 Pod

'C

. This

rllows the rcfrigeran(

to

pass

from

rhe suclion chamber to

thc bp of

thc unloadc': This rcduction

in

prcssu'.c

and

the

sp.iDg in

thc unloder pisloD

allows {hc valvc ro lift.

This

w;llcausc

lhe rclrigennt to pNs

back inro lhe sucrioncavily

ol lhe comprcssor rr

the

samc

time rhc

chccl,

valve

lo€aled

in

(he

head scars

and

prevenrs

rhc

discharge

pressure

fn)rn

shon cycling in

the compressor This

conlinues unril rhc

solcnoid

dc-cncrgizcs. Al

this

(ime

the discharg€ prcssure

builds up. se ls offthc pon

to lhe suction

cavily and rhe sys-

tcnr

punrps

wilh four

cylinders.

CAUTION:

Unloader heah arc

used on spcci&l

conprcssor

bodies that haw

s rcturn

gas passage.

Do not use

unloadcr heads on

conpressor bodics that

do

not havc th. .eturn gas passaAe.

Check Out

l.

with

unloadcr

dc-energized. conpressor

should

punp

down nomally

15 to 20 in. Hg vacuum

(-51

to

-68

kPa)

and should hold a 15 in.

Hg

vacuum

Csl

kPa)

for three

2. Using

an auxiliary ba[ery,

energize and de-energize

unloader

solenoid on compressor

cylinder hcad white

the compressor is

running. An audible

noise

will

b€

made when

unloading. as well

as a

pressure

change in

borh suction

and discharge.

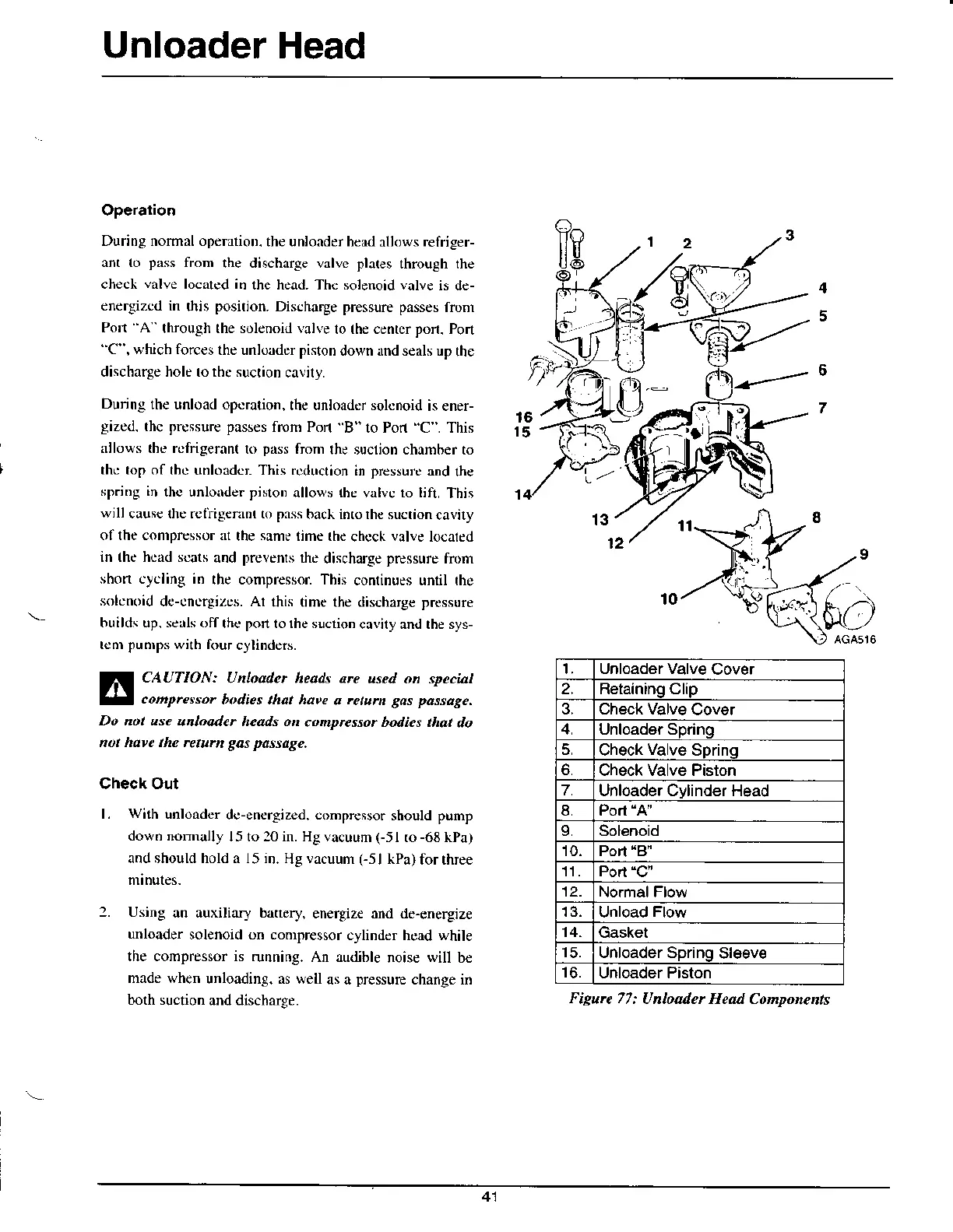

Unload6r Valve

Cover

2. Retainino Clip

3. Check Valve

Cover

Unloader Sprinq

5.

Check

Valve

Spring

Check Valve Piston

7.

Unloader Cylinder Head

8.

L Solenoid

10. Porl

'8"

11. Port

"C'

Normal Flow

Unload

Flow

14.

Gasket

Unloader Spring

Sl6ev€

Unloader Piston

Figurc 77:

Unloader Head Components

41

Loading...

Loading...