Disassembly and Reassembly

(Rev.

7. 12l01)

body

until ir boroms out. The flange on the

pickup

tube

will

force rhe O-ring inb the oil inralie hole.

1^

4. Insmll the oil sump- Instnll theoil sump bolts and wash-

es. Torque

the oil

sump

boltr in rwo.lep\ u.ing J

criss'cross

pnttem.

See

"Torque

Values" on

pnge,l.

OIL PUMP

Ramoval

CAUTION: Thc oil

punp

esscmblr is a

Nccsnn

device with clase cleamnces. AII

paft

must

be

kcpt

clean, the i'ork area must bc

kep,

ckan, and

oil

applied to the

punp

nust be clean. Contanination

bt dbt debtu, chips, or burn coud cause rhc oil

punp

to

Iail

pfcnaturely

Par'I. must be

prcteeted

f?on

nick and

sctulches.

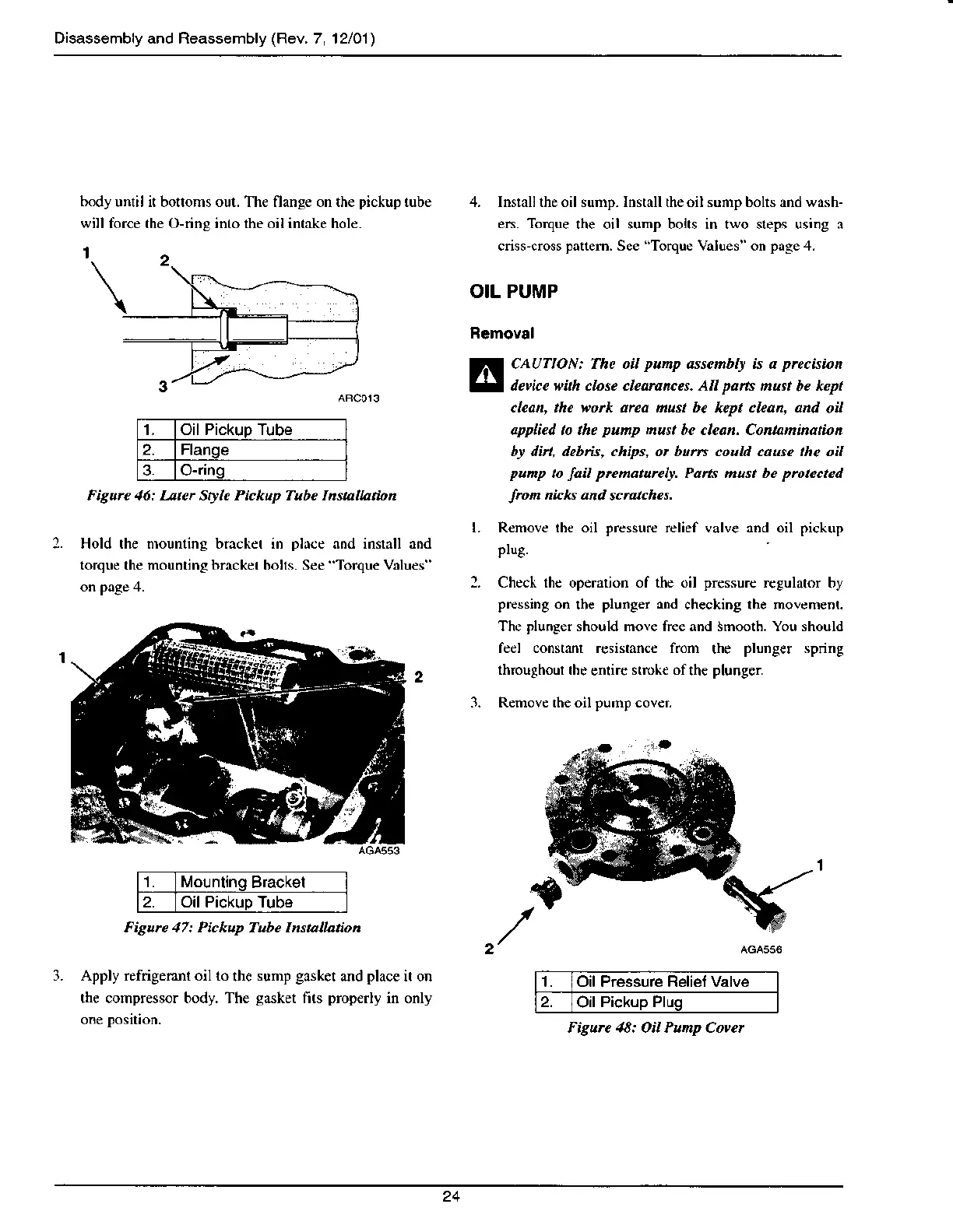

Oil Pickup Tube

Flange

3. O-ring

Figure 46: Iat.r Stylc Pickup Tubc Instalhtion

Hold the nrcunting bmcket in

plfte

nnd instill and

torqu€ the mounting bracker bolls. See Torque Values'

on

page

,1.

l. R€move ihe oil

pressure

relief valve and oil

pickup

pl,'C.

l. Checl lhc operation of the oil pressur€

rcgulator by

pressing

on

$e

plunger and

checking lhe molem€nt.

The

plunger

should move free and Smooth. You should

f<l consrrnr rrsisrrn(d from

th(

plune€r

\pnnE

throughour the

enlire

stroke of

th€

plunger

3. Remove the oil

pump

cover.

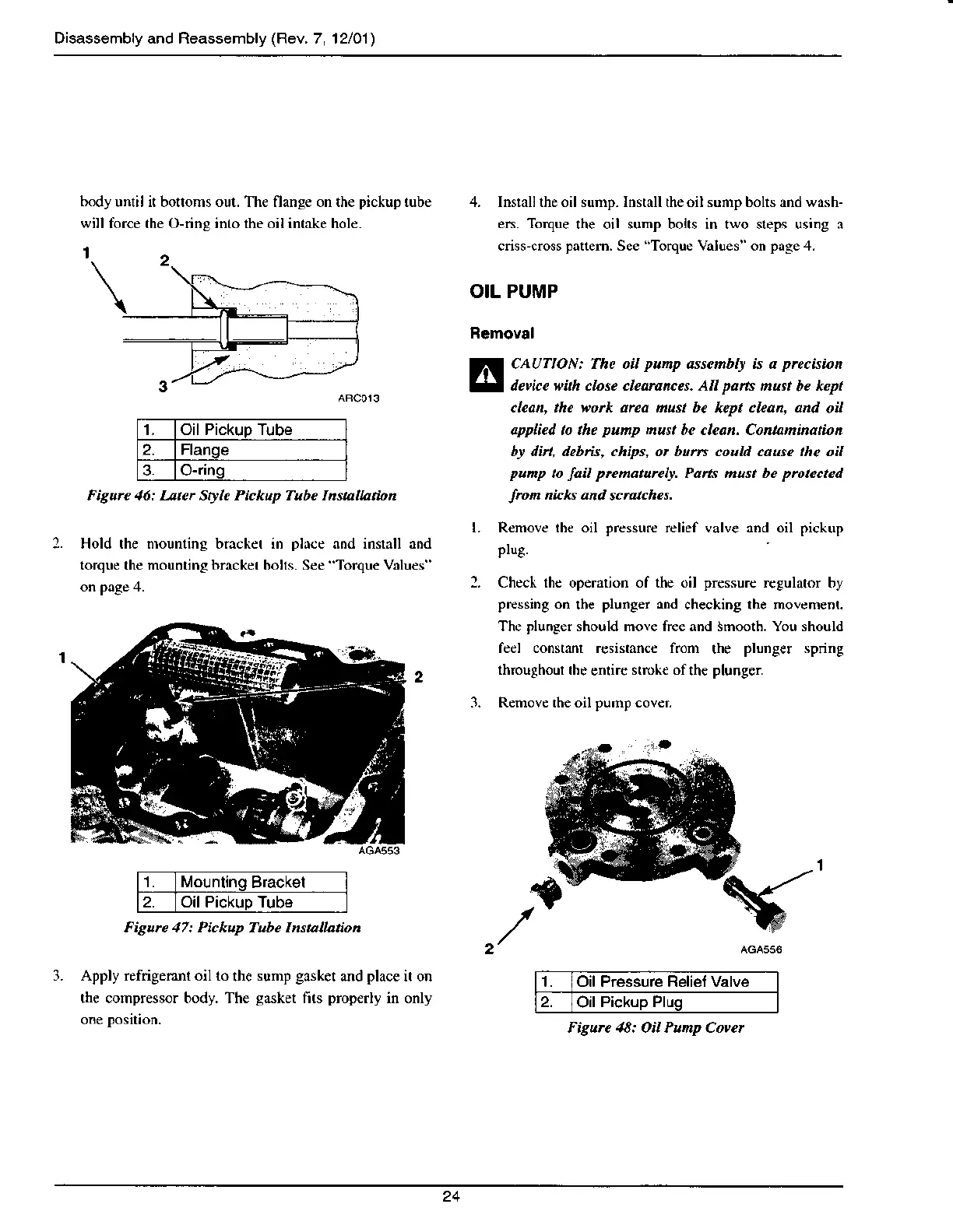

Mounlinq

Brackel

2. Oil Pickup Tube

Ficure 47: Pickup Tube Install^rion

Apply refrigeranl oil 1()

the

sump

gasket

and

place

it on

the comprelsor body. The

gasket

fits

properly

in only

1 Oil Pressure Relief Valve

2.

Oil

Pickuo Pluo

Fisurc 18: Oil Punp Cover

24

Loading...

Loading...