Disassembly and Reassembly

(Bev.

7, 12/01)

beforc adenpting to llrosen thc sel

Installation

ot Spring Loaded Neoprene

Bellows Type Seal

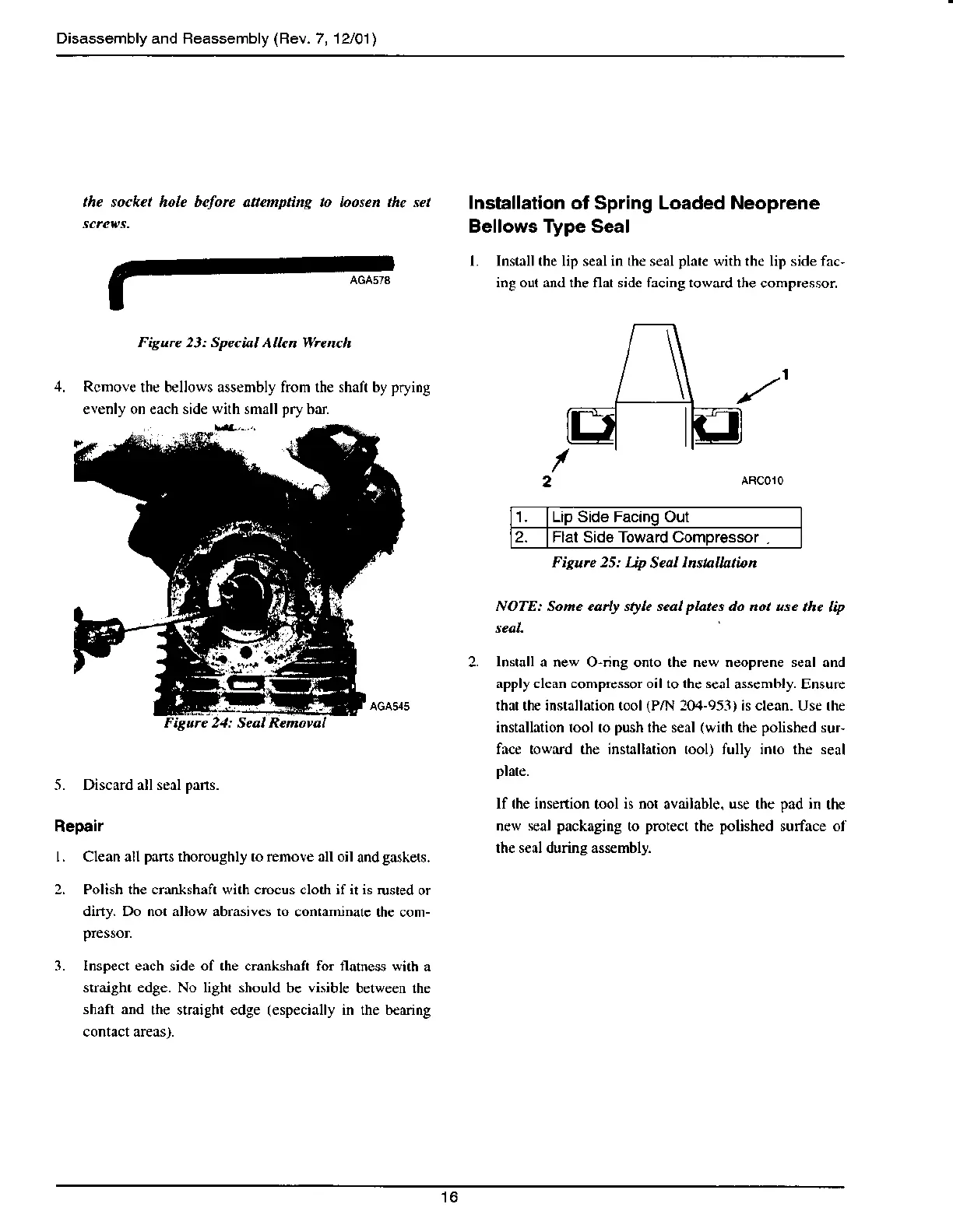

L lnshll lhe lip seal in the senl

plnte

with the lip side fac,

ing out and the flat sidc facing toward

the compressor.

t"t

Lip Side Facing Out

2. Flat Sid€ Toward Compressor

Figutu 25: Lip

SeaI

Insta

ltion

Fisu.e 23: Special

A enWrcnch

Rcmove

thc bellows assernbly from the shaft by

prying

evenly on each side with small

pry

bar.

5. Discard all seal

pans.

Repair

L Clean all

pans

thomughly to remove all oil

and

garkets.

2. Polish the crankshaft with crocus cloth if it is rusted

or

dirty. Do not allow abrasives to

conramitrale the com-

3. lnspect ench side of rhe crankshafr for flatness wirh

a

sraight edge. No lighr should

be

visible

between the

shafi and

the straighl edge

(especially

in the bcaring

NOTE: Sone carly stlle seal

plates

do not se

the lip

seal.

lnstall

a new O-riog onlo the new neopr€ne seal and

apply clean compressor oillorhe s€al

assembly. Ensure

rhat the installation tool(PAl 204-953) is clean. Use rhe

installation rool to

push

ihe seal

(with

the

polished

sur,

frc€ toward the installation tool) fully inro the seal

lf the insenion

tool

is nor

available.

use

thc

p.d

in

the

new

seal packaging

to

protect

the

polished

surface of

rh€ seal during assembly.

16

Loading...

Loading...