Leak Testing,

Storage,

and Break In

LEAK TESTING

Leal test the compressor

silh

retiigerant

gas

such as

R-ll.h ar npproximately 70

psi

r483

kPa).

STORAGE

Thermo King compressors rcbuilt in the field should b€

prop.rly

sealed,

leak ch€cked.

evacuated and charg€d

with

20,t

5 psi

(

138 ! 34

kPr)

dry nitrogen to ensure that th€y do

nol b€cone conianrinaled if they are to be stored for nny

lcngfi of limc

rfrer

ovcrhauling.

Covcr

plates

are avail$lc

for all coDprcssors for rhis puryosc.

BREAK IN

The following proccdu(- nusl

b€

followcd for any com-

pressor

that

has

had an oil

punp

installed and/or

has

been

stored for any

length

oftinre.

CAUTIoN:

U

a no,t

Iactory

re'nsnufoctu.ed co'n-

prcssor is rebuilt

and

sto.ed

lor

anr anount

oI tine,

a brcak in

prcccdurc

must be donc *hen the com-

pressor

is instaled or the oil

ptnp

coau

fail.

II a

non

Iacto.r

rcbuilt conprcssot is sod

orar thc

countcr a tag describine thc brcak i

procedure

must accompant the conprcssor.

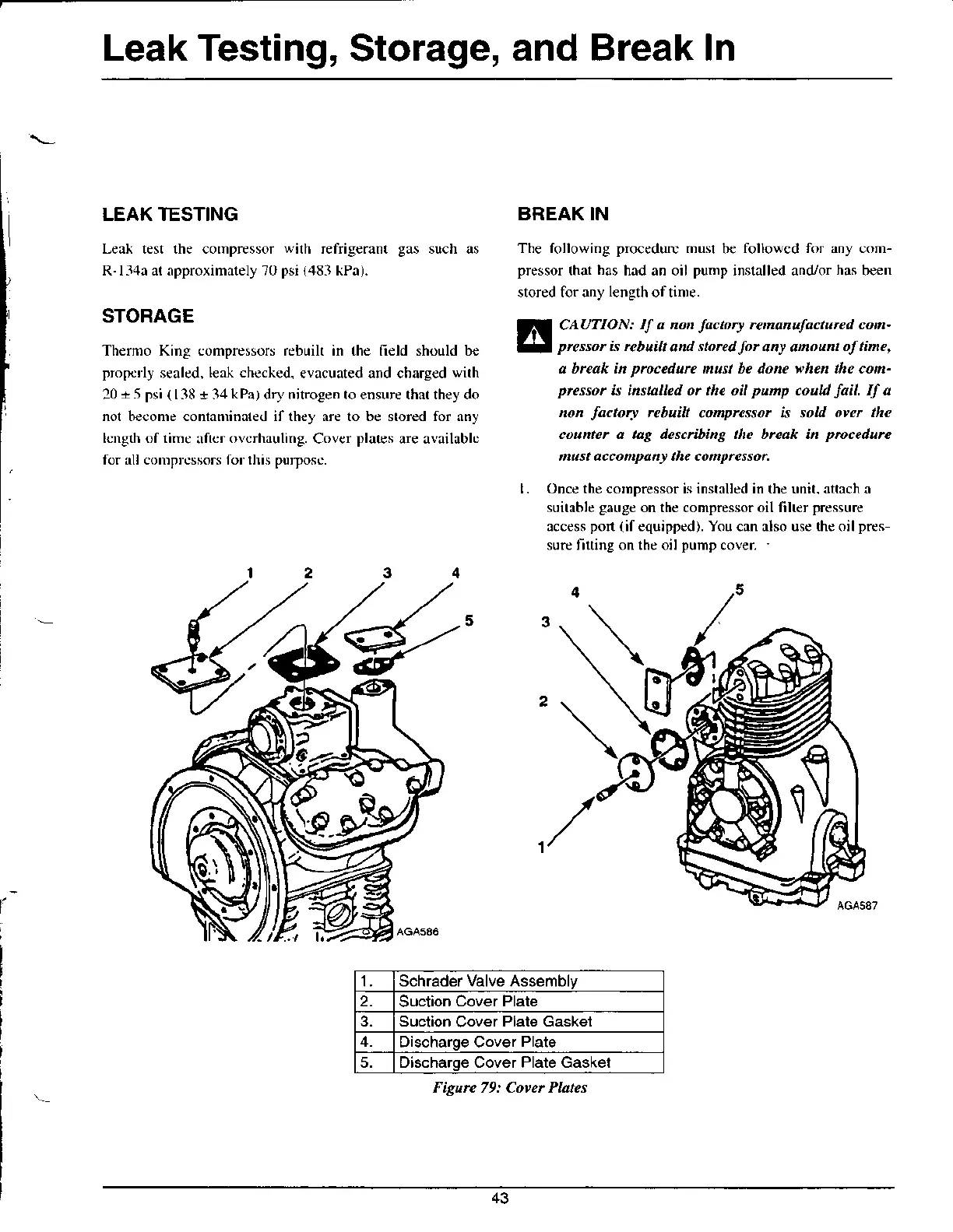

Once the compressor is installed in the unit. attach a

suitable

gaug€

on the compressoroil filter

pressure

access

pon

(ifequipped).

You can also use the oilpres

sure filting on the oilpump cover.

l.

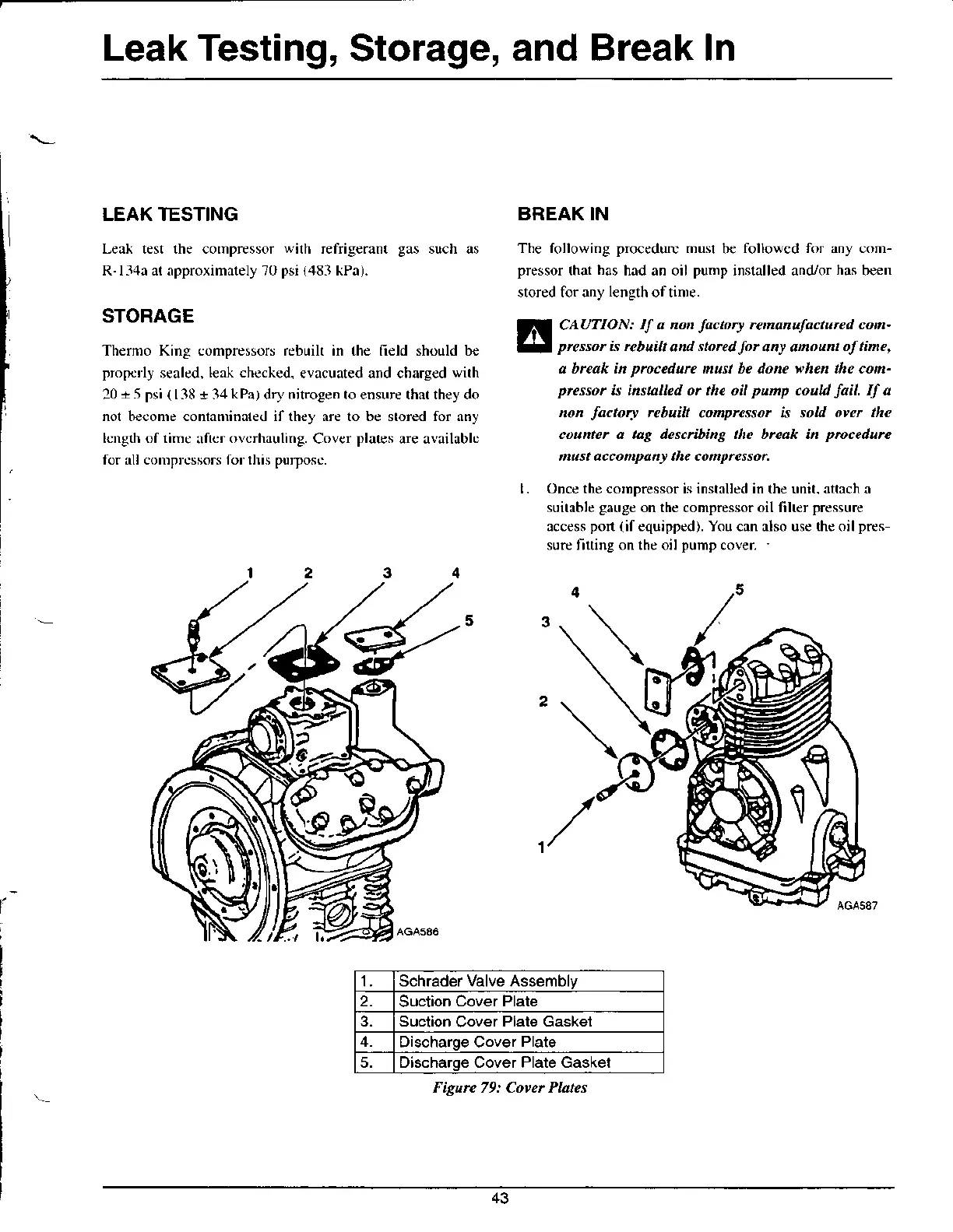

Schrader Valve Assemblv

2.

Suction

Cover Plate

3. Suction Cover Plate Gasket

4.

Discharoe Cover

Plate

5. Discharge Cover

Plate

Gasket

Figun 79: Cover Plates

43

Loading...

Loading...