Disassembly and Feassembly

{Rev.

7. 12/01)

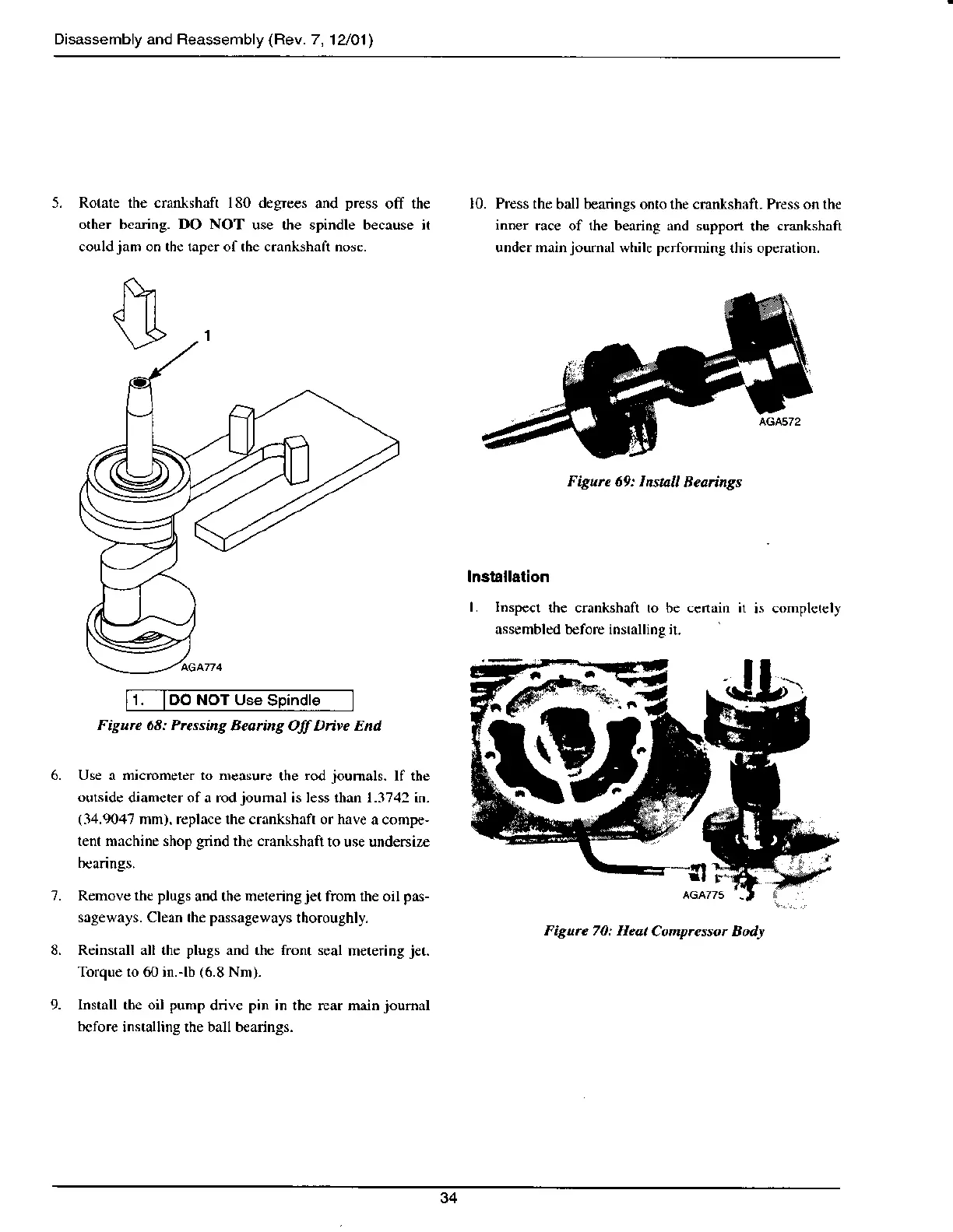

5. Rolate the cranlishaft l8O degrees

and

press

off the

other beeing. DO NOT

use the spindle because it

couldjam on th€ taperofthe crankshaft nose.

10. Press the

ball b€arings onto the cmnkshaft. Press on the

inner

race of the bearing and suppon

|he

cmkshafi

under mainjoumal while performing

this operation.

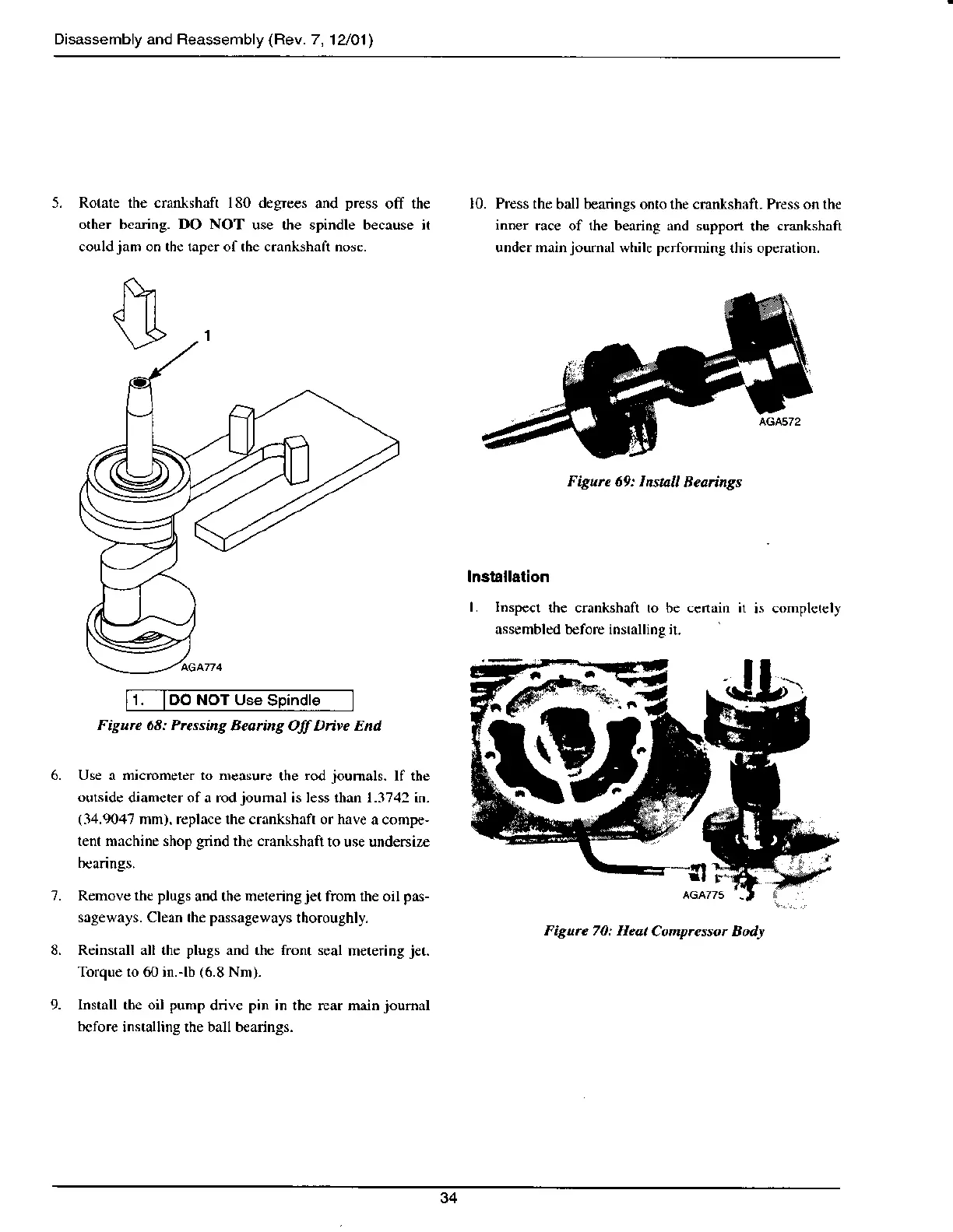

Figure 69: Ins.a

Bearings

lnsiallation

L Insp€cl

the crankshft to be

assembled before instdling it.

1.

IOO

NOT Use

SDindl€

6.

1.

Figun 68: Prcssins

Beotins OJJ D^,e End

Use a micrometer to nr€asurc

the

rod

joumals.

lf the

oulside

diamcter of a rod

joumal

is less than 1.3742 in-

(34.9047

rnrn). replace the crankshaft or have

a compe,

tenl mrchine shop

grind

the cnnkshaft

to use undenize

Remove rhe plugs

and the meleringjet fmn the oil

pas-

sageways. Clem the passageways

lhoroughly.

Reinsrall all the

plugs

and the front seal

metering

jet.

Torque 1o 60 in.-lb

(6.8

Nrn)-

lnstall tbe oil pump

drive

pin

in the rear rnain

joumil

bcfore

installing the ball b€arings.

Figure 70: Hcat

Conprcssor Rody

9.

34

Loading...

Loading...