- 22 -

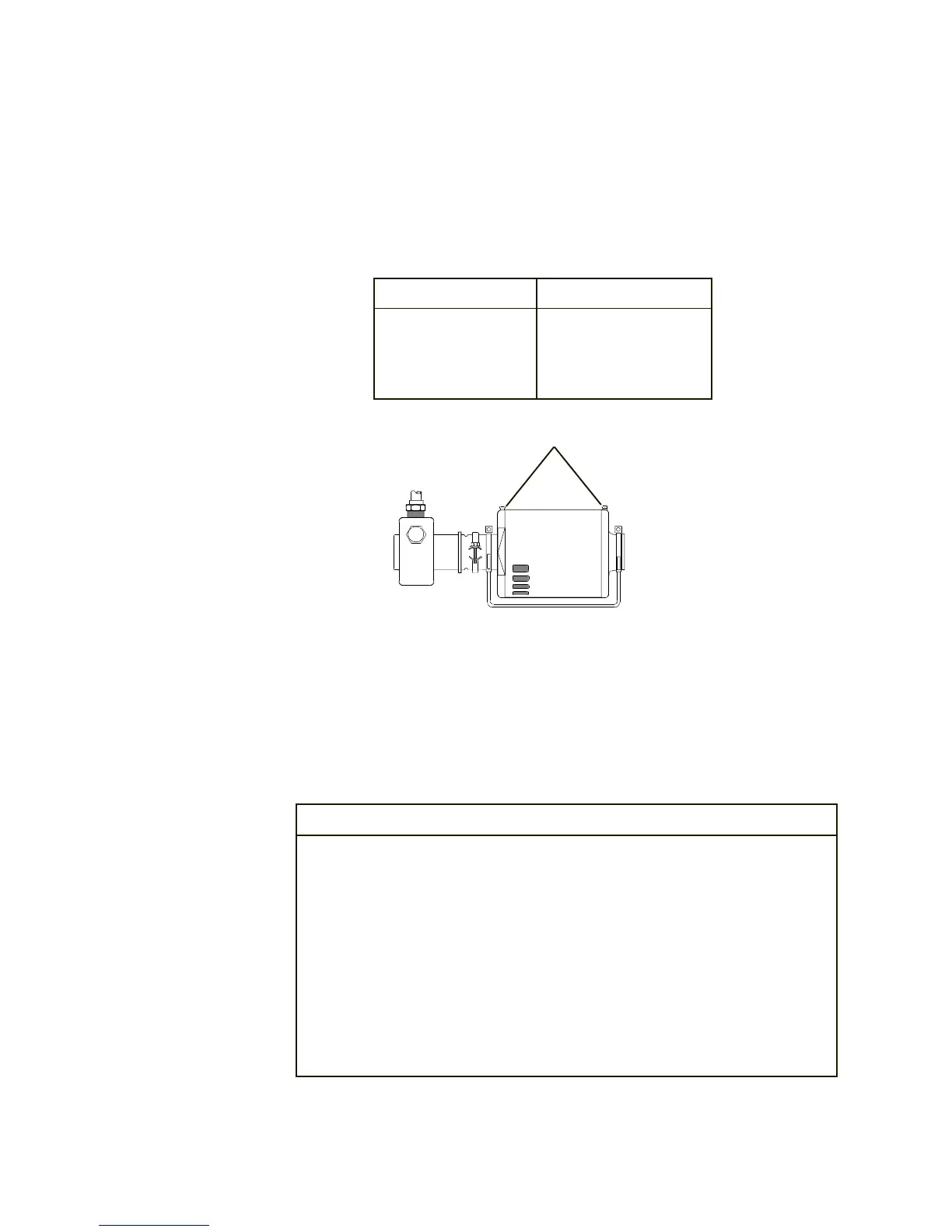

Duty Cycle Oiling Frequency

Continuous Once every year

Intermittent Once every 2 years

Occasional Once every 5 years

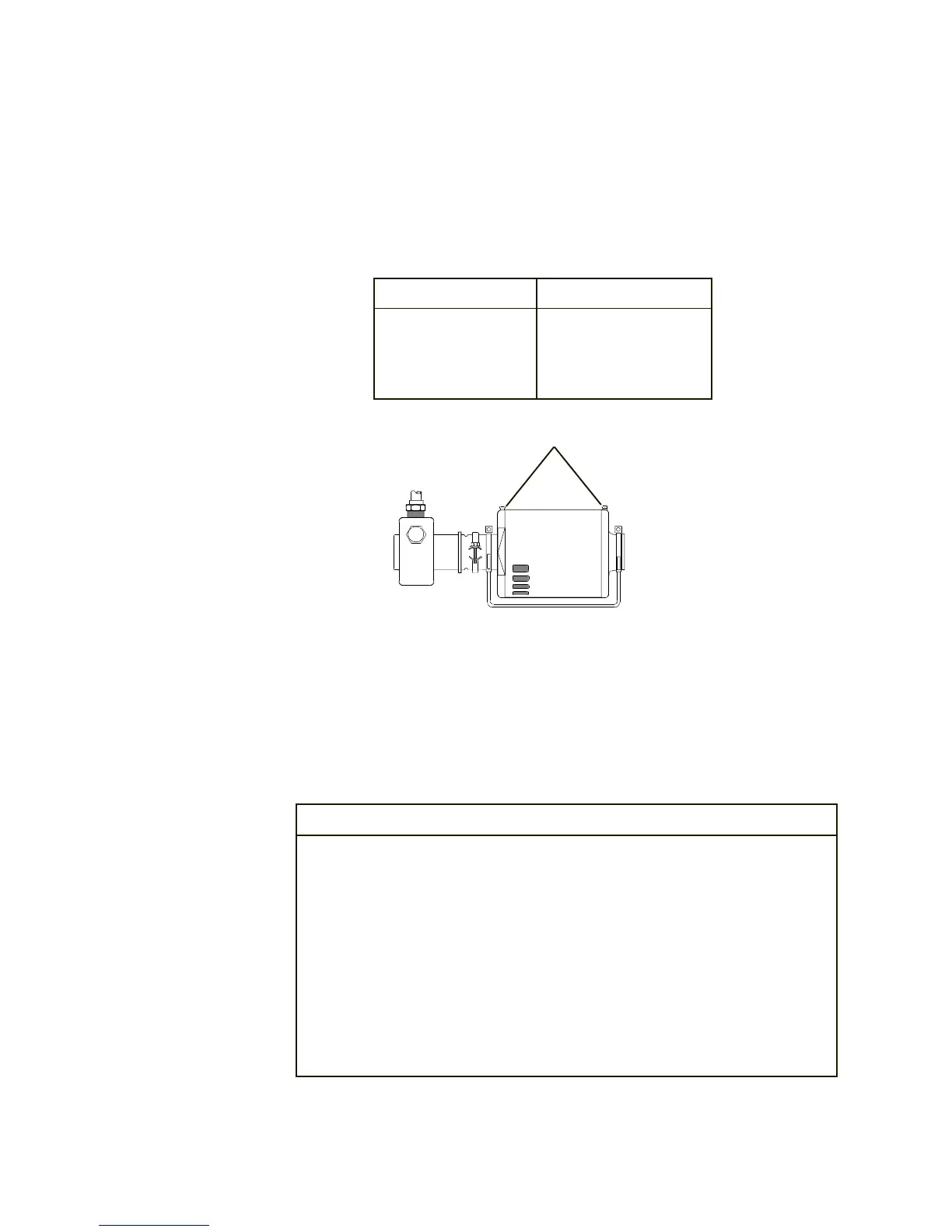

Fill Holes (Typical)

Hoses

The unit's internal and external hoses and clamps should be inspected and

tightened on at least a semiannual basis.

Suction Discharge Pressure

Speed Check

Unit Pump Refrigerant Suction PSIG Discharge PSIG Speed °C/Min

CFT-25 PD-1 R134a 36 -38 160 - 170 4.8

CFT-25 MD-30 R134a 25 - 28 145 -160 4.0

CFT-33 PD1/2 R134a 42 - 45 180 - 200 3.0

CFT-75 PD1/2 R134a 37 - 41 170 -185 4.6

CFT-150 PD2 R22 70 270 2.8

CFT-300 PD2 R22 88 - 94 265 - 280 6.8

CFT-300 CP-55 R22 85 - 90 268 - 280 6.8

Standard temperature 60 Hertz units, derate 17% for 50 Hertz Units. +20°C fluid temperature,

unit in the COOL mode, +20°C ambient. 100% water in the reservoir. Wrapper removed.

Pump Motor Lubrication

Some PD pump motors require periodic lubrication. Refer to the pump label on

the rear of the unit to identify the type of pump in your unit.

PD pumps use sleeve type bearings with large reservoirs. Oiling instructions

are generally posted on each motor. In the absence of instructions, add

approximately 30 to 35 drops of SAE 20 non-detergent oil to each bearing on

the following schedule (SAE 20 = 142 CS viscosity):

Loading...

Loading...