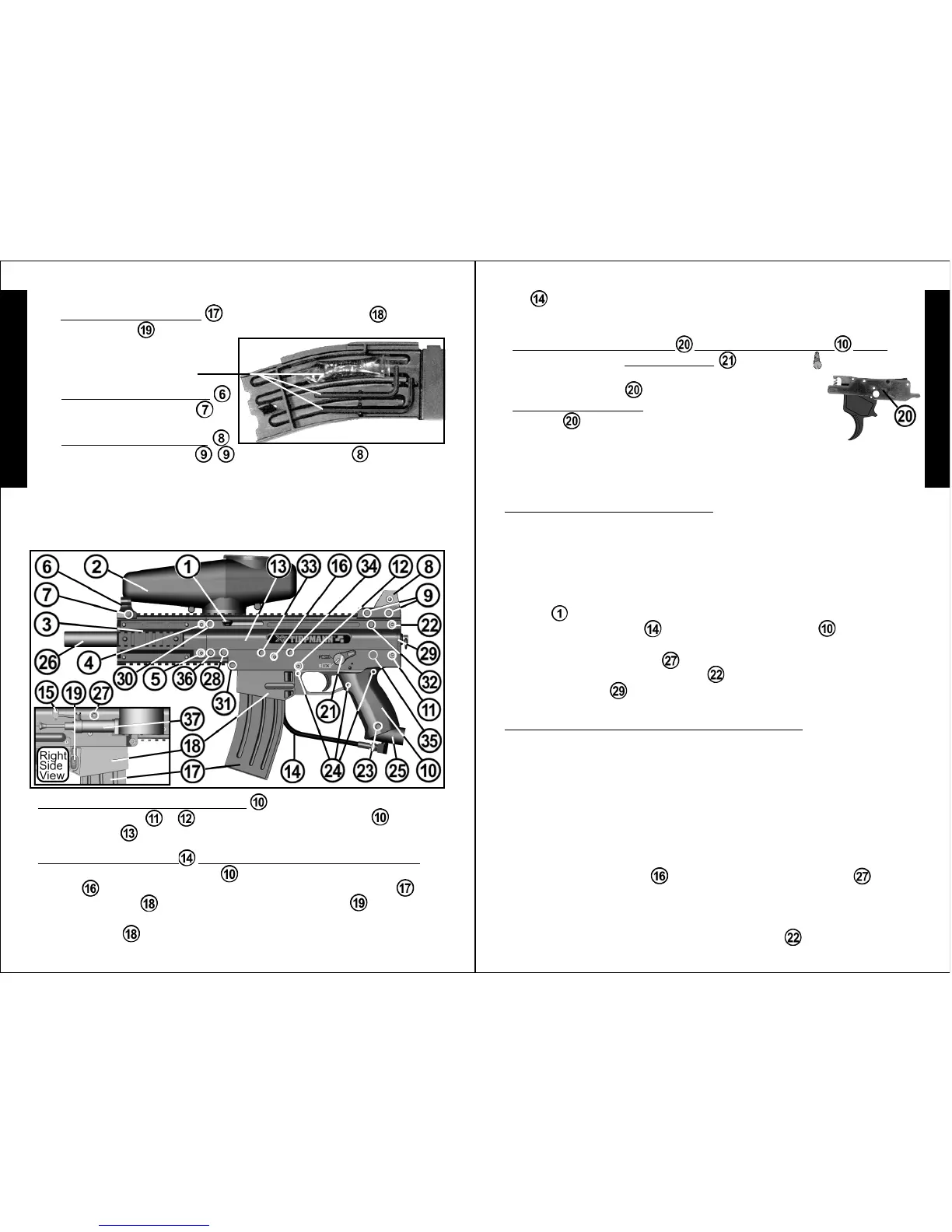

TOOLS: The magazine contains Tools and lubricating oil for your marker.

6)

❏

To remove the magazine from the magazine base press the

magazine button

(on right side of the magazine base), then slide

magazine down and out. Store

tools in magazine after use (shown

with 2 allen wrenches and oil.

To reinstall drive assembly parts and lower receiver:

1)

❏

Clean inside upper receiver and removed parts.

2)

❏

Inspect and replace any damaged parts. Lubricate

❏

the front bolt

o-ring,

❏

the rear bolt o-ring,

❏

the linkage arm and the drive spring/

guide pin with a few drops of Tippmann

®

paintball marker oil (or other

premium paintball marker oil) before reinstalling them.

3)

❏

Insert valve into power tube with Tombstone cutout aligned down to

match power tube cutout. (Insert tombstone adapter to check fit).

4)

❏

Insert reassembled parts - front bolt, power tube/valve, rear bolt/rear

bolt plug, with linkage arm facing up, until tombstone adapter can be

inserted, long push pin

replaced and velocity screw can be

accessed. You may need to jiggle marker while sliding parts in.

5)

❏

Insert the guide pin into the drive spring and

❏

drive spring into the

rear bolt plug.

❏

Insert the end cap, while keeping the guide pin centered

in it.

❏

Install the upper end cap short push pin .

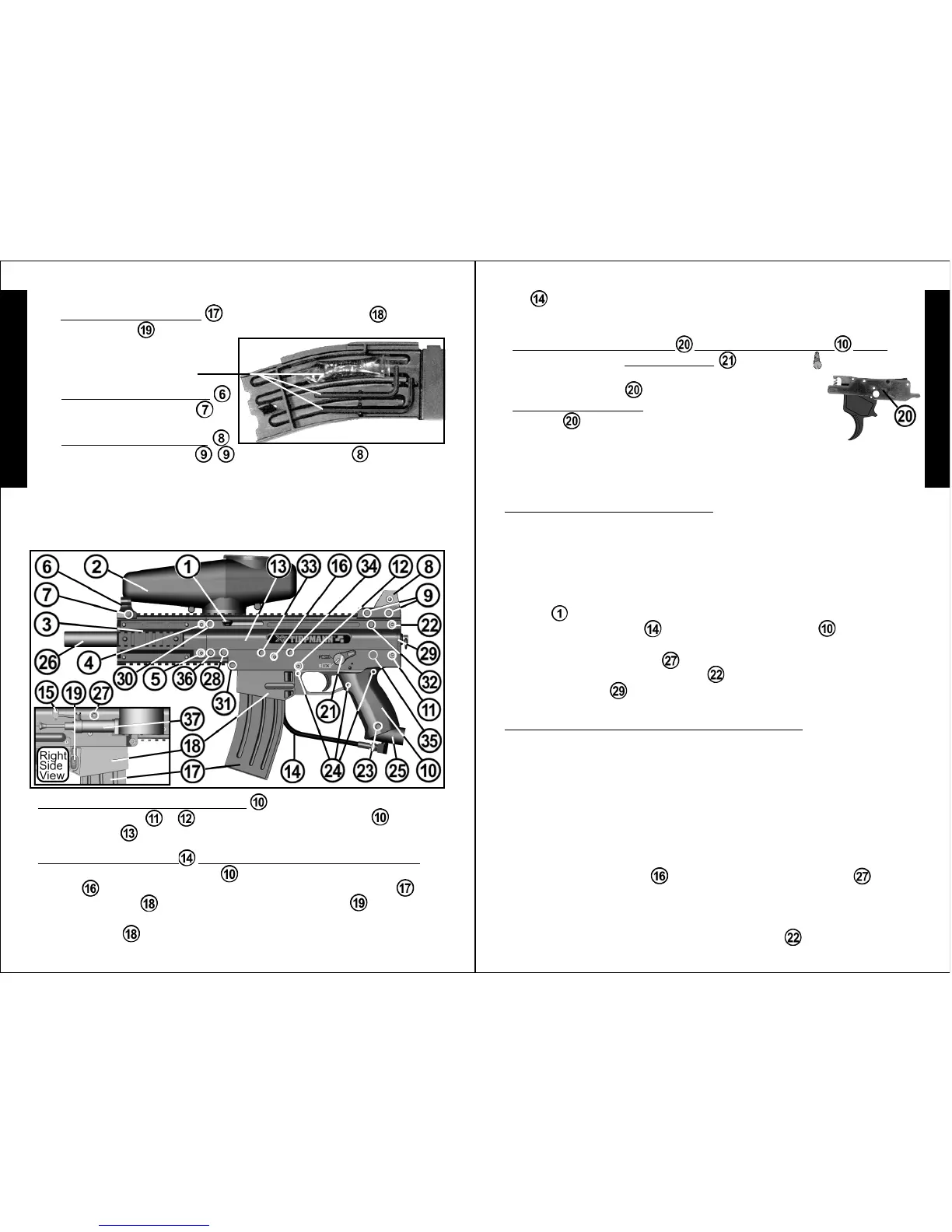

• To remove the lower receiver (grip) :

❏

Remove the 2 long lower

receiver push pins

/ and pull the lower receiver from the

upper receiver

.

Receiver Disassembly

❏

Eye protection designed for paintball use must be worn by the user and

any person within range.

•

To access trigger parts:

❏

Pull left plate off trigger

assembly

. Do not remove the 5 dowel pins from

the right plate. See trigger assembly on page 9.

•

To remove trigger assembly from the lower receiver (grip):

❏

Rotate the Safety Selector Switch straight up

and

❏

pull it out left side of lower receiver.

❏

Pull up on

the trigger assembly

keeping it intact.

•

To remove the gas line / Tombstone from the upper receiver:

❏

Remove the lower receiver see above.

❏

Remove the long

push pin

from the upper receiver.

❏

Remove the magazine from

the magazine base by pressing the magazine button (on right side

of magazine base), then slide magazine down and out.

❏

Slide

magazine base

back until it stops, then down.

❏

Pull down on gas

13

12

Drive Assembly Removal and Installation

NOTE: It is not necessary to disassemble the upper receiver to access

and service the drive assembly internal parts.

To remove the drive assembly parts: front bolt, power tube, valve, rear

bolt/rear bolt plug, linkage arm, drive pin guide, drive spring and end cap

(parts shown on pages 8 and 9).

1)

❏

Remove air supply before any disassembly: Unload marker, remove

the air supply as outlined on page 10 and put the marker in the uncocked

position before beginning to disassemble it. To uncock the marker, hold

the bolt cocking handle back 3/4 - then pull the trigger and release handle

forward

which will uncock the marker.

2)

❏

Remove gas line and lower receiver (grip) see Receiver

Disassembly instructions on page 12.

3)

❏

Screw velocity screw in past receiver.

4)

❏

Remove last push pin (short) holding end cap in place.

5)

❏

Pull end cap out and tilt marker up, drive assembly parts should

slide out the back. You may need to jiggle marker while sliding parts out.

Receiver Disassembly / Assembly

(continued on page 13)

Receiver Disassembly / Assembly

(continued on page 14)

Receiver Disassembly / Assembly (continued from page 12)Receiver Disassembly / Assembly (continued from page 11)

7)

❏

To remove the Front Sight :

Remove Front Sight Screw

and slide the front sight off .

8)

❏

To remove the Rear Sight :

Remove 2 rear sight screws

/ and the Rear Sight .

❏

FIRST: perform steps 1), 2), 3), 4), 5), 6), 7) and 8) as outlined on

pages 11 and 12 before beginning Receiver Disassembly.

line to remove the gas line/Tombstone. NOTE: If you remove the

gasline from the Tombstone, when reinstalling, inspect and oil the o-ring

and be careful not to overtighten and strip threaded parts.

E

N

G

L

I

S

H

E

N

G

L

I

S

H

Loading...

Loading...