Do you have a question about the Titan PowrLiner 2850 and is the answer not in the manual?

Key steps to follow before operating the equipment.

Safety rules to follow during work interruptions.

Explains the meaning of safety symbols used in the manual.

Details potential dangers like injection injury and prevention.

Dangers associated with high pressure hoses and prevention measures.

Risks of flammable vapors igniting or exploding.

Dangers of inhaling or contacting paint/solvent vapors.

General warnings about potential injury or property damage.

Safe operation and handling of the gasoline engine.

Requirements for gasoline, including octane and alcohol content.

Describes the unit's use as a line striper for various applications.

Details the types of paints and materials that can be processed.

Explains the atomization process using high pressure without air.

Describes the technical construction and how the engine drives the pump.

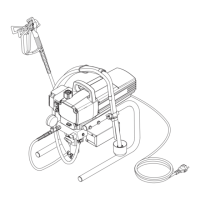

Labels and lists the numbered components of the sprayer system.

Details engine power, fuel capacity, pressure, volume, and viscosity.

Specifies operating temperature, humidity, altitude, and storage conditions.

Instructions for preparing the sprayer for use, including one/two gun setup.

Guidance on adjusting spray gun bar and vertical position for optimal spraying.

Specific safety and procedural advice for cleaning with flammable liquids.

General steps for cleaning the sprayer after use.

Instructions for wiping down the unit's outer surfaces.

How to clean or replace the suction filter for optimal performance.

Steps for cleaning the high-pressure filter to ensure proper spray patterns.

Procedure for rinsing and cleaning the spray gun after use.

How to clean or replace the intake filter in the spray gun.

Recommended annual check by technicians and national regulations.

Essential checks to perform before each use of the equipment.

Checks to be performed at regular intervals for wear and cleaning.

Recommendations for daily, first 20 hours, every 100 hours, and weekly engine checks.

Tips for efficient engine operation, air filter cleaning, and oil changes.

Procedure to adjust spring tension for proper spray gun trigger response.

Lists common problems, their causes, and solutions for the unit.

Step-by-step guide for replacing the relief valve.

Instructions for removing and installing a new power switch.

Procedure for removing and installing the transducer assembly.

Steps for servicing or replacing the gear and slider assembly.

Instructions for disassembling and inspecting gear housing and crankshaft.

Steps for removing, checking, and lubricating the slider assembly.

Procedure for removing and replacing the clutch armature assembly.

How to create the proper "set back" for the clutch armature assembly.

Steps to remove clutch rotor, field, and drive shaft components.

Procedure for sliding and securing the clutch field.

Steps for installing the drive shaft and pump housing assemblies.

Instructions for aligning and securing the gear and clutch housings.

How to check and adjust the gap between the clutch armature and rotor.

Procedures for cleaning, reversing, or replacing fluid section valves and seats.

Detailed steps for removing, cleaning, and installing fluid section packings.

Guidance on choosing the correct spray tip for optimal performance.

Instructions for cleaning and maintaining spray tips for durability.

List of compatible accessories for the sprayer unit.

| Type | Airless Paint Sprayer |

|---|---|

| Horsepower | 0.75 HP |

| Voltage | 120 V |

| Hose Length | 50 ft |

| Spray Tip Size | 0.021 in |