40

TTBPP52

In more detail . . .

Troubleshooting

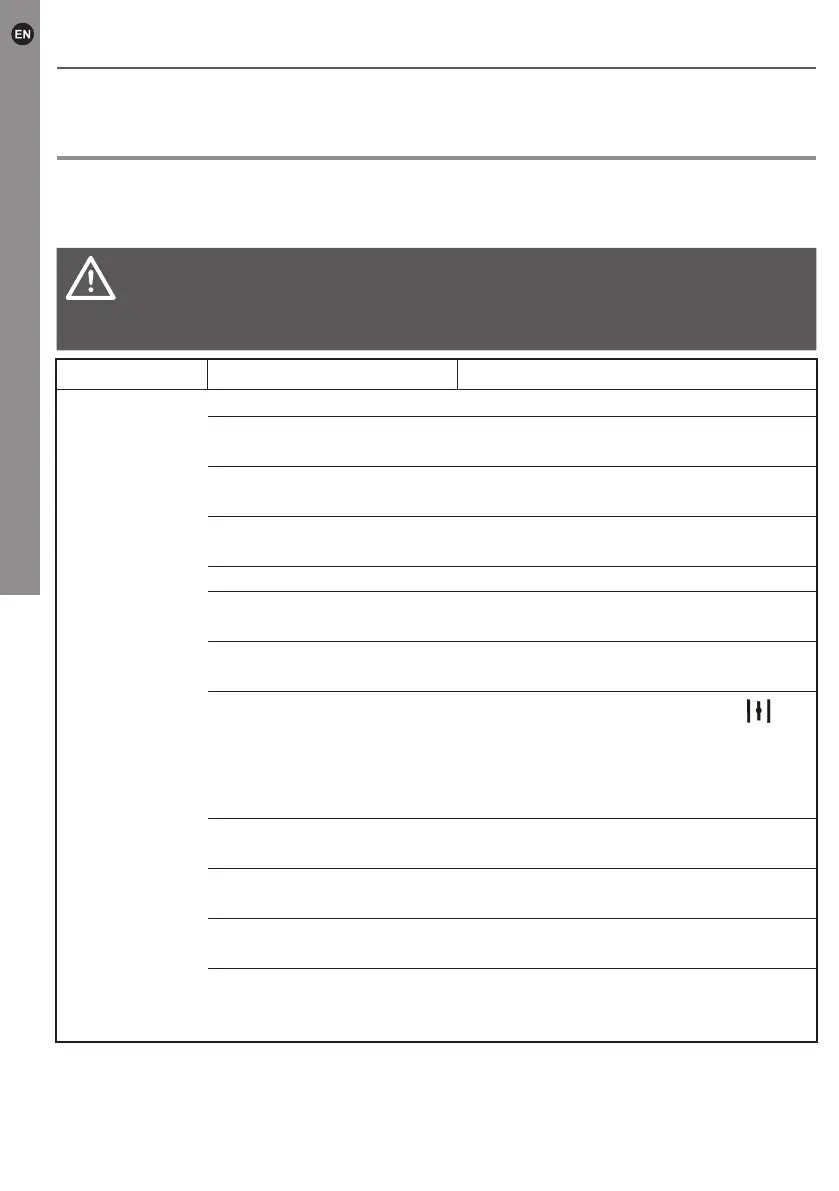

Suspected malfunctions are often due to causes that the operators can x themselves.

Therefore check the machine using this section. In most cases, the problem can be

solved quickly.

WARNING! Only perform the steps described in these instructions! All further

inspection, maintenance and repair work must be performed by an authorised

service centre or a similarly qualied specialist if you cannot solve the problem

yourself!

Problem Possible cause Solution

Engine does

not start

Fuel tank empty? Fill the fuel tank.

Stop lever at STOP

position?

Set the lever to idle position. Follow the

engine starting procedure.

Incorrect starting

procedure?

Follow the engine starting procedure.

Spark plug connector not

rmly attached?

Attach the spark plug connector rmly.

Spark plug is wet? Dry the spark plug.

Spark plug connector is

dirty?

Clean the spark plug connector.

Mufer is dirty? Clean the spark arrestor screen on the

mufer.

Excess fuel in the

combustion chamber?

Set the choke lever to the RUN

position and pull the recoil starter

handle several times.

If the engine does not start: remove

spark plug and dry the electrodes.

Spark plug is soiled (tip is

rusted)?

Clean or replace the spark plug.

Primer has been pressed

at cold start?

Press the primer 7 times and restart.

Follow the engine starting procedure.

Gap between electrodes is

too large?

Set gap between electrodes between

0.6-0.7 mm0.6-0.7 mm.

Incorrect fuel or incorrect

mixture?

Stop the engine, empty tank, then ll

up with the correct mixture of fuel to oil

(40:1).

Troubleshooting

Loading...

Loading...