Page 11@)1&/2:(+.:4=&A02'/.)+'B&6=24'2&:4==&CD###DE#FDFEC#,Item 57863 57864

GH@<IJKHLMI<MHMN< OHGLN&P<QRLMSP<QRLMS&ILTG G<IUT

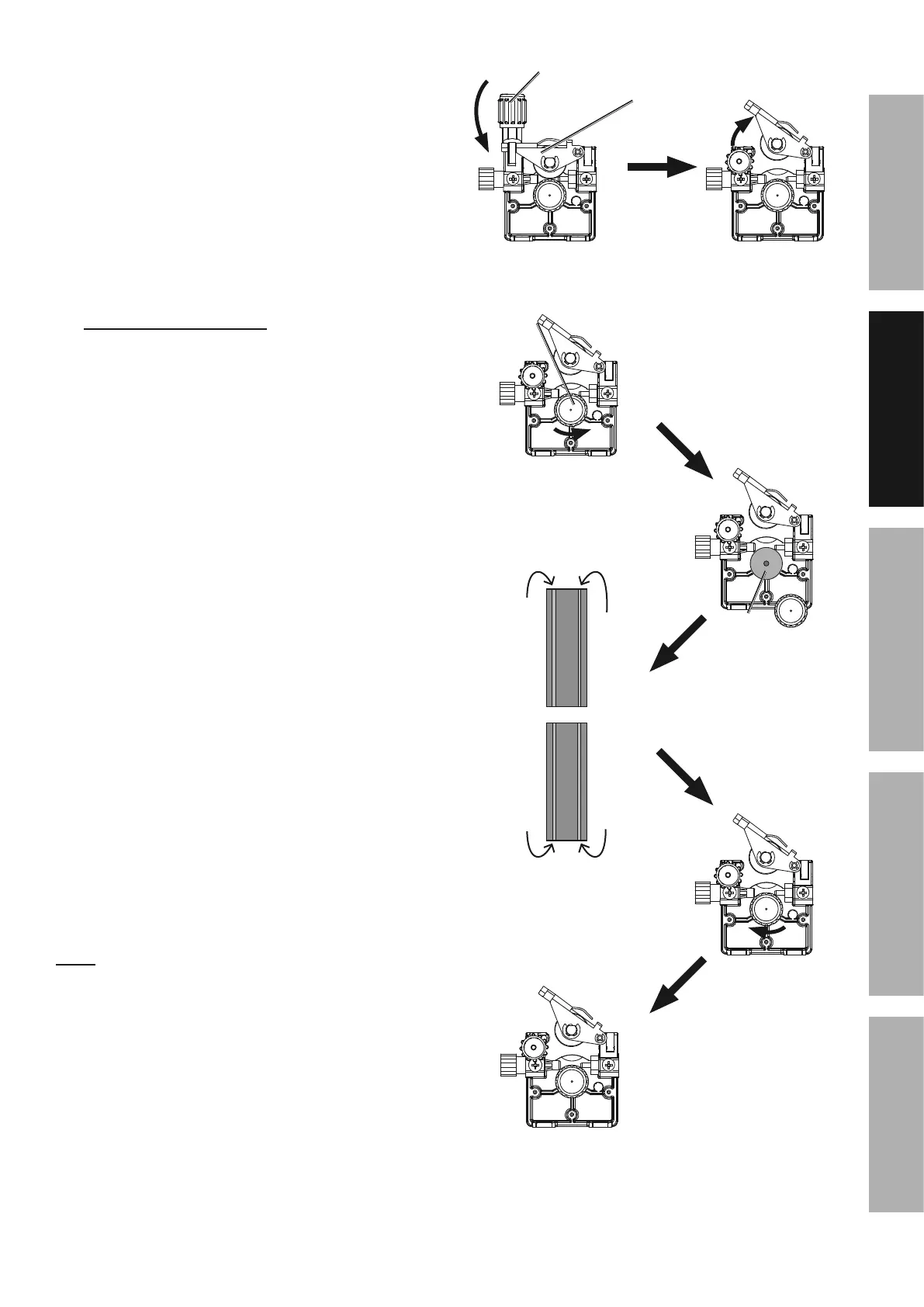

13. Turn the Feed Tensioner knob counterclockwise to

loosen it enough to pull it down to remove tension.

The spring-loaded Idler Arm will move up as shown.

14. @22>&V)==21&L+'/10:/.)+'5&

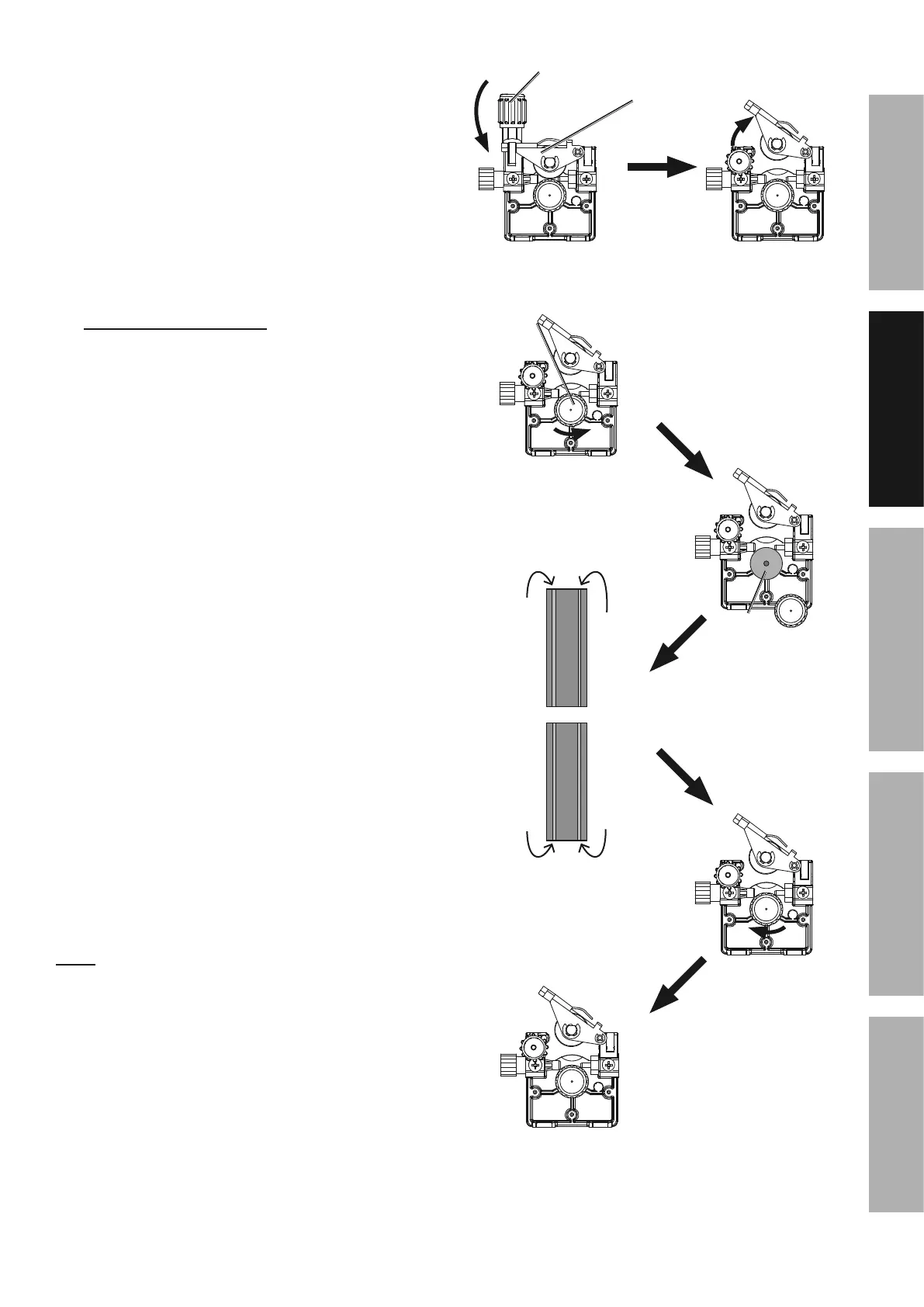

Check that the Feed Roller is correct for the

type of wire being used (solid core or flux-

cored) and that it is turned to properly match

the wire size marked on the Wire Spool:

a. Unscrew the Feed Roller Knob counterclockwise.

b. Remove the Feed Roller Knob to

expose the Feed Roller.

c. Flip or replace the Feed Roller as needed and

confirm that it is the correct Roller for the type of

wire being used and that /(2&+0;321&'()*.+9&

.'&/(2&'4;2&4'&/(2&*.12&>.4;2/21&)+&/(2&G6))=,

M)/25 The knurled groove is used for flux-cored wire.

The V-grooves are used for solid / MIG wire.

d. Screw the Feed Roller Knob back into

place to secure the Feed Roller.

L>=21&H1;

@22>&I2+'.)+21

@22>&V)==21&

Z+)3

@22>&

V)==21&

HH

OO

NN

RR

F,FEF&

-D91))Y2

F,Fb!&&

-D91))Y2&

G)=.>&N)12&

-DS1))Y2

F,FE!&

-D91))Y2

F,FEF&7&F,FE!&

]+01=2>&91))Y2

Loading...

Loading...