Page 26 @)1&/2:(+.:4=&A02'/.)+'B&6=24'2&:4==&CD###DE#FDFEC#, Item 57863 57864

GH@<IJ KHLMI<MHMN<OHGLN&P<QRLMS P<QRLMS&ILTGG<IUT

O01+DI(1)09(

O4'2&;4/21.4=&;2=/'&4*4XB&&

=24Y.+9&4&()=2&.+&/(2&*2=>,

TWGGLOQ<&NHUG<G&HMR&GWQUILWMG

1. P)1]6.2:2&)Y21(24/.+95&

Reduce current and/or wire feed speed.

2. I14Y2=&'622>&/))&'=)*5

Increase travel speed and ensure

that travel speed is kept steady.

3. <\:2''.Y2&;4/21.4=&4/&*2=>5&

Reduce wire feed speed.

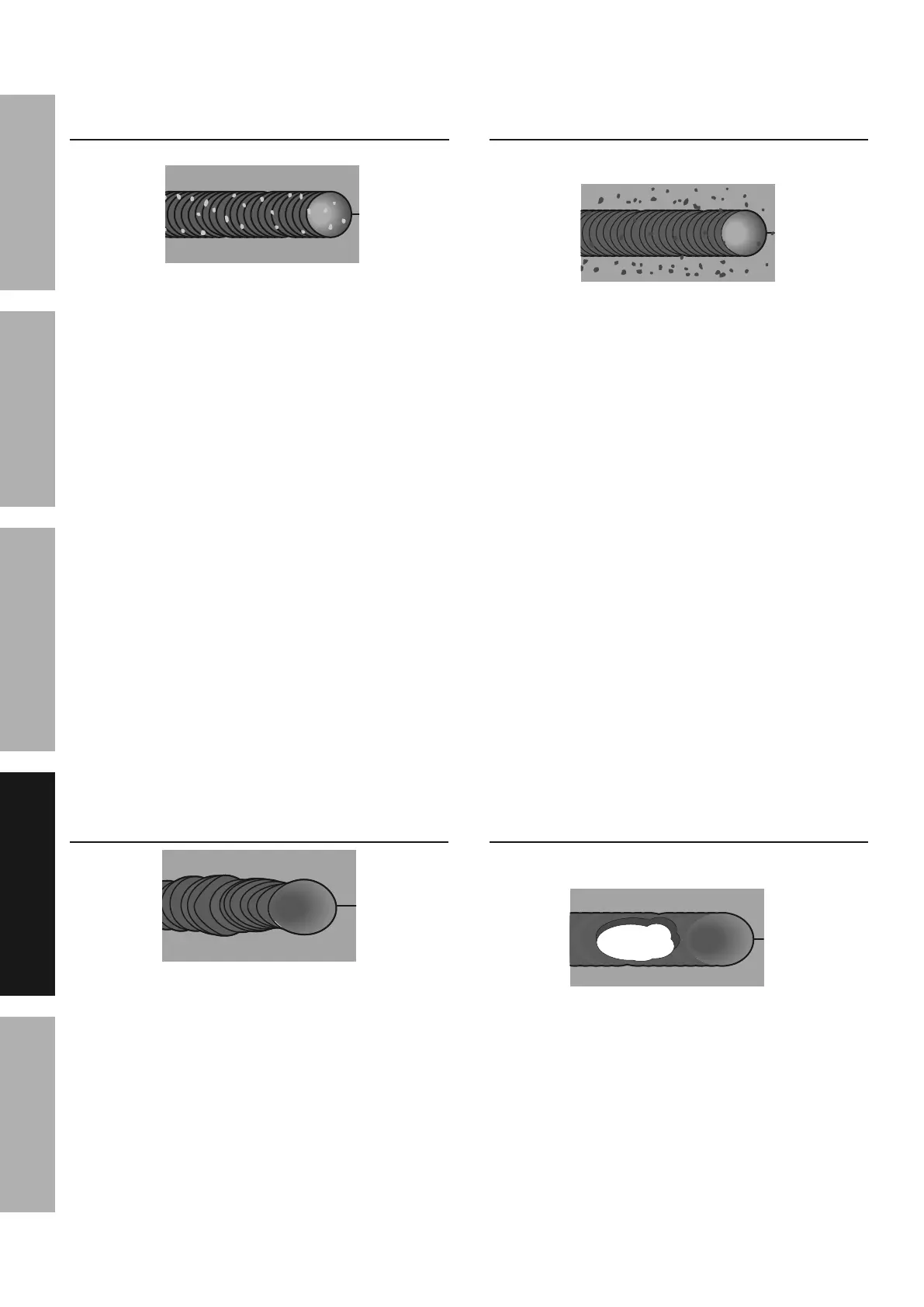

TOP

VIEW

N1))]2>7P4YX&O24>

TWGGLOQ<&NHUG<G&HMR&GWQUILWMG

1. L+4::014/2&*2=>.+95

Use two hands or rest hand on steady surface.

2. L+:)+'.'/2+/&/14Y2=&'622>5&

Maintain steady travel speed.

3. NIPR&/))&=)+95

Reduce CTWD.

TOP

VIEW

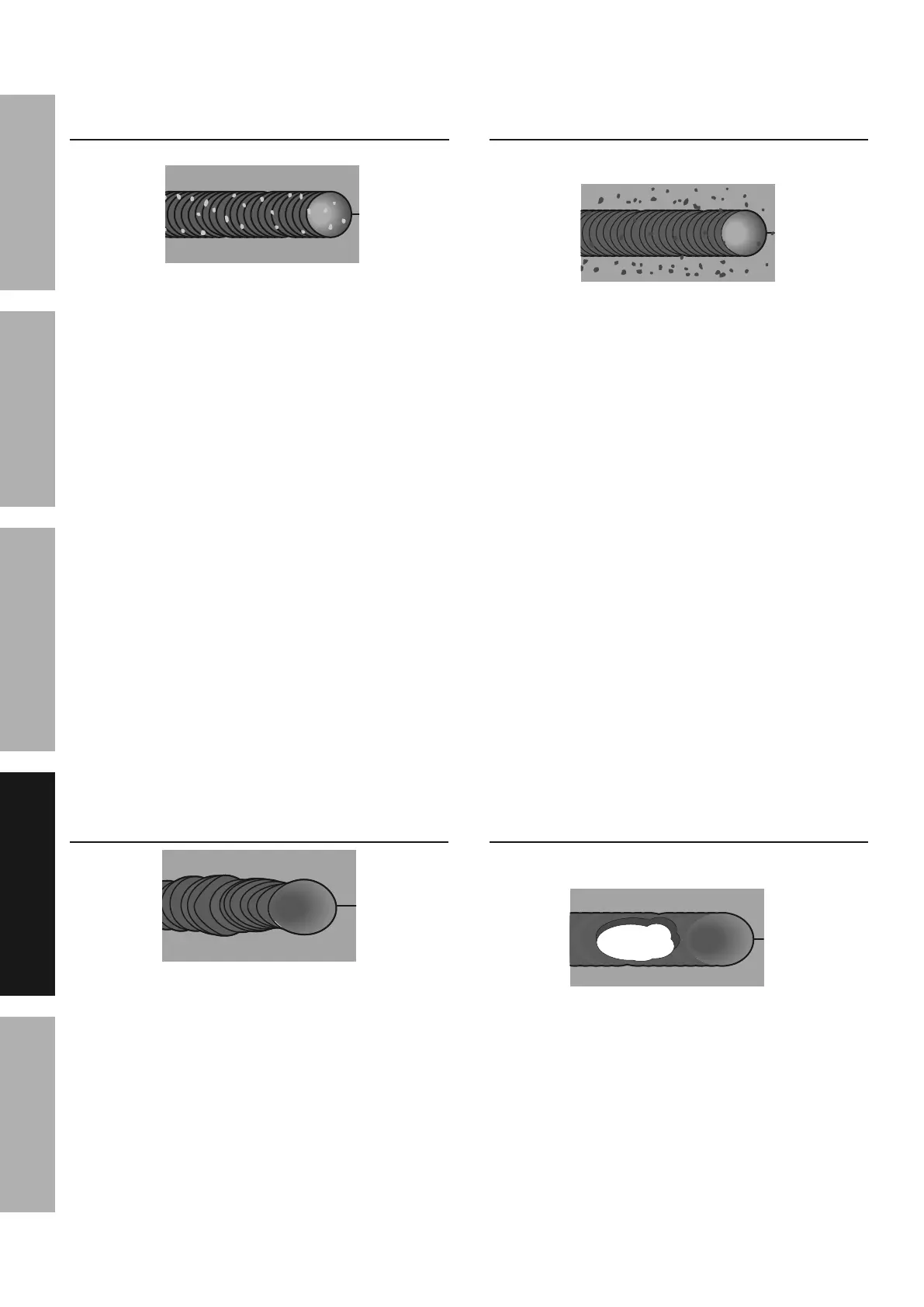

T)1)'./X

G;4==&:4Y./.2'&)1&()=2'&.+&/(2&324>,

TWGGLOQ<&NHUG<G&HMR&GWQUILWMG

1. L+:)112:/&6)=41./X5

Check that polarity is set correctly

for type of welding.

2. Insufficient shielding gas (MIG only):

Increase flow of gas.

Clean nozzle.

Maintain proper CTWD.

3. Incorrect shielding gas (MIG only):

Use shielding gas recommended by wire supplier.

4. R.1/X&*)1]6.2:2&)1&*2=>.+9&*.125

Clean workpiece down to bare metal.

Make certain that wire is clean and free

from oil, coatings, and other residues.

5. L+:)+'.'/2+/&/14Y2=&'622>5&

Maintain steady travel speed.

6. NIPR&/))&=)+95

Reduce CTWD.

TOP

VIEW

<\:2''.Y2&G64//21

@.+2&'64//21&.'&+)1;4=,&

G64//21&/(4/&.'&914.+X&4+>&=4192&.'&4&61)3=2;,

TWGGLOQ<&NHUG<G&HMR&GWQUILWMG

1. R.1/X&*)1]6.2:2&)1&*2=>.+9&*.125

Clean workpiece down to bare metal.

Make certain that wire is clean and free

from oil, coatings, and other residues.

2. L+:)112:/&6)=41./X5

Check that polarity is set correctly

for type of welding.

3. Insufficient shielding gas (MIG only):

Increase flow of gas.

Clean nozzle.

Maintain proper CTWD.

4. P.12&822>.+9&/))&84'/5&

Reduce wire feed speed.

5. NIPR&/))&=)+95

Reduce CTWD.

TOP

VIEW

Loading...

Loading...