ENGLISH

V4-007 J EN

Originalbetriebsanleitung

37

9

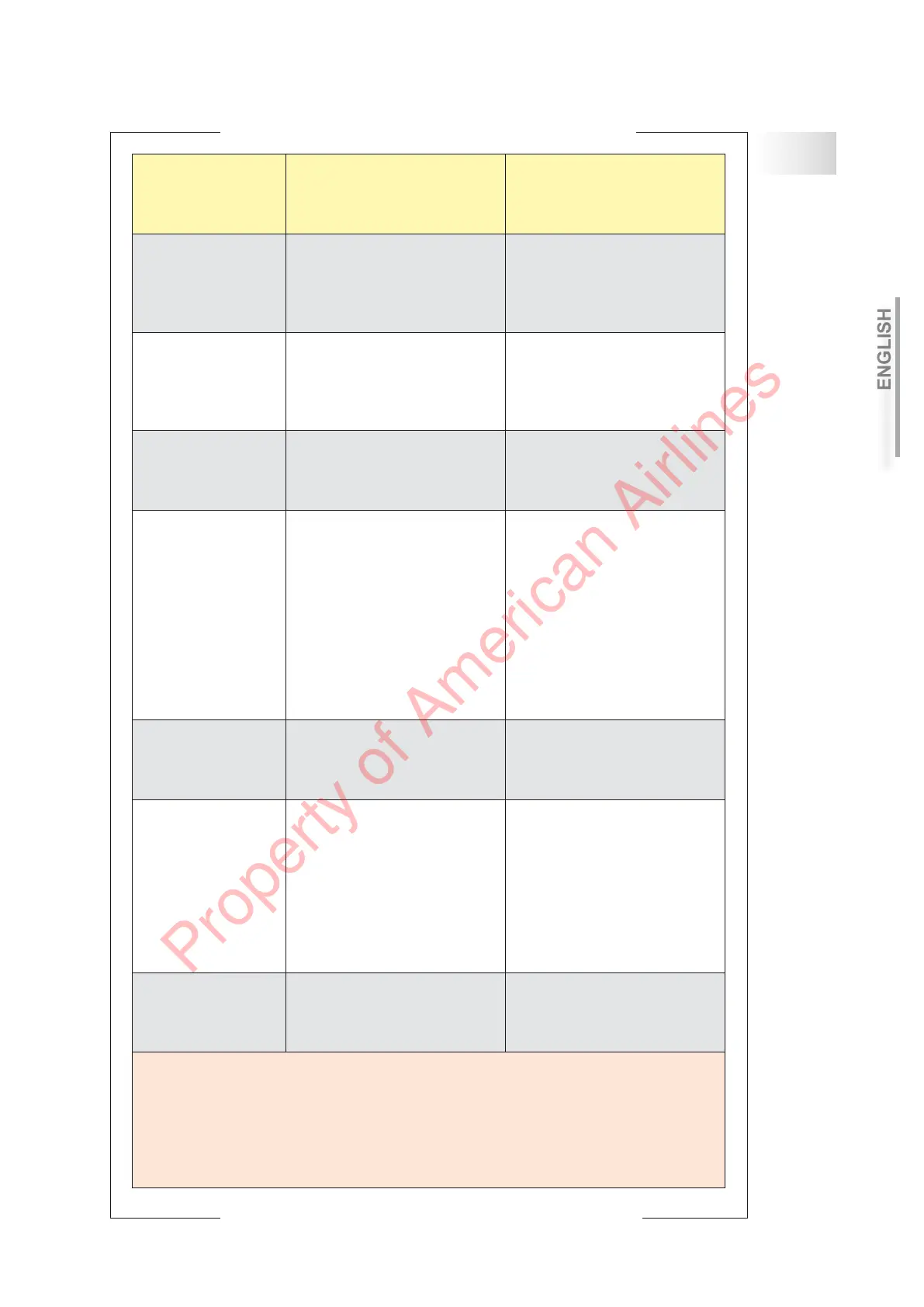

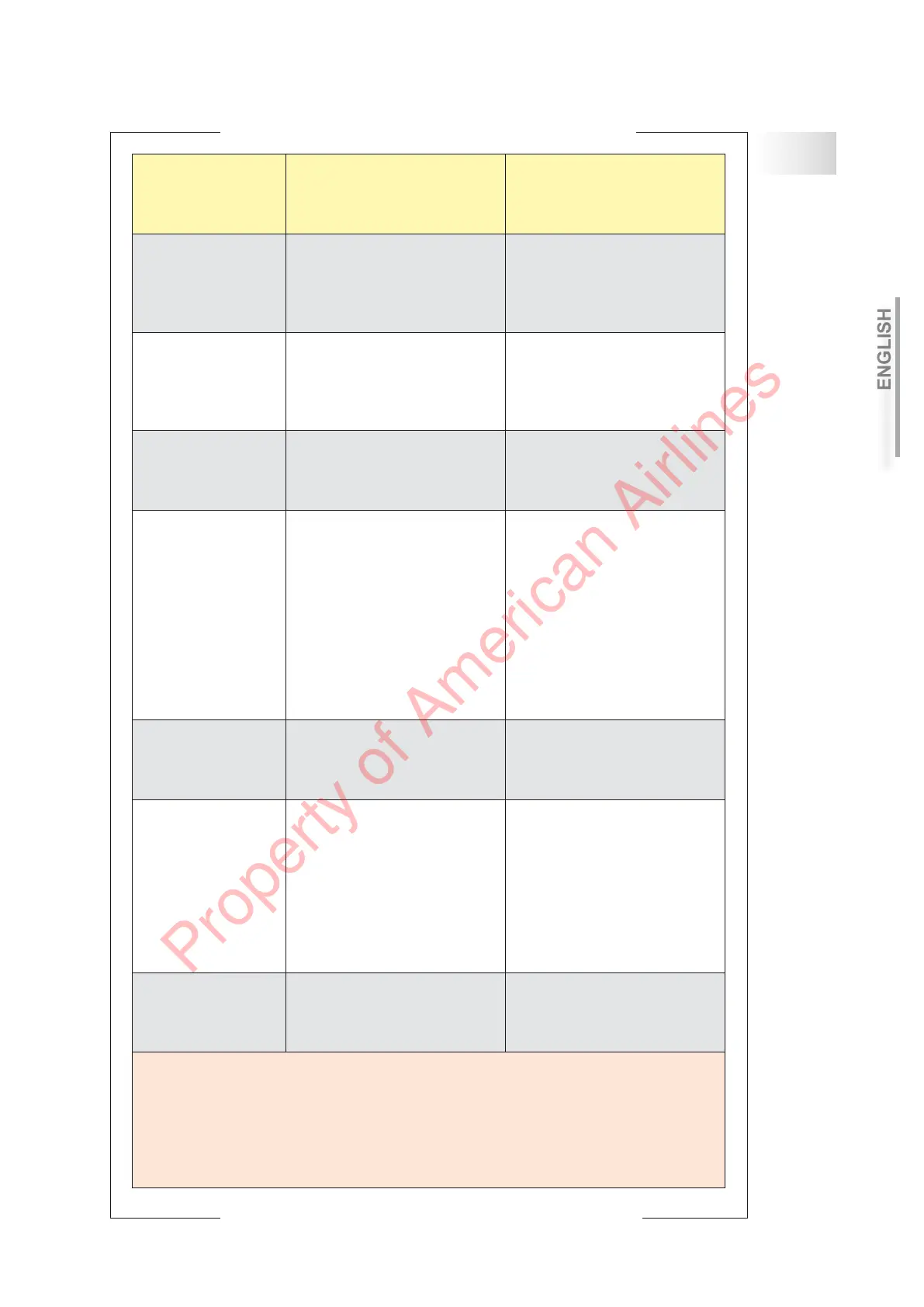

Error messages/

Faults

What do I do

if . . ?

Possible

causes . .

Remedy . .

...if damage to the

machine occurs as

a result of a faulty

supply point?

Motor and electr. control •

have been connected to

two different networks.

Connect motor and •

control voltage to a single

supply network.

Alternatively: Use a cur-•

rent monitoring relay.

...there is a break-

down due to "intake

pressure"?

Intake lter or starting •

strainer soiled

Slide valve in intake pipe •

closed

Blank tted•

Clean, replace •

Open slide valve •

Remove blank•

...a breakdown oc-

curs due to "com-

pression discharge

pressure"?

Overload at discharge side•

Closed discharge side•

Blank installed•

Performance limits•

Open slide valve•

Remove blank•

...there is a break-

down due to an

increased

"discharge tempera-

ture"?

Decrease in intake pressure•

Increase in discharge •

pressure

Deterioration in volumet-•

ric efciency

Increase in intake tem-•

perature

Too little exhaust air •

expelled

Acoustic hood exhaust air •

louvre soiled

Check intake pipe•

Check discharge pipe•

Check play setting, •

replace components if

necessary

Ensure there is sufcient •

inlet air

Ensure there is sufcient •

exhaust air

Clean•

...there is a break-

down due to an

increased oil tem-

perature?

Oil cooler soiled•

Oil cooler ventilator faulty•

Thermostat controller •

faulty

Clean•

Replace•

Replace•

...there is a break-

down due to insuf-

cient oil?

Oil lter contaminated•

Oil pump faulty•

Oil pump is taking in air•

Oil regulating valve faulty •

or stuck

Oil level too low•

Replace•

Replace•

Check intake pipe•

Move spindle; if there is •

a soft knocking on the

housing, replace

Rell oil; establish and •

eliminate reason for lack

of oil

...the compressor is

not oil-tight?

Oil demister has failed•

Oil chamber seal faulty•

Screwed connections in •

oil lines loose

Perform demister maintenance•

Replace seals•

Retighten; replace•

Whenever intervention has been necessary as a result of a fault occurring, the fol-

lowing must be checked:

Ease of running in rotary piston machine•

Non-contact rotation•

Lubricating oil level•

Correct functioning and connection•

Compliance with the safety and warning information•

Property of American Airlines

Loading...

Loading...