ENGLISH

V4-007 J EN

Originalbetriebsanleitung

36

9

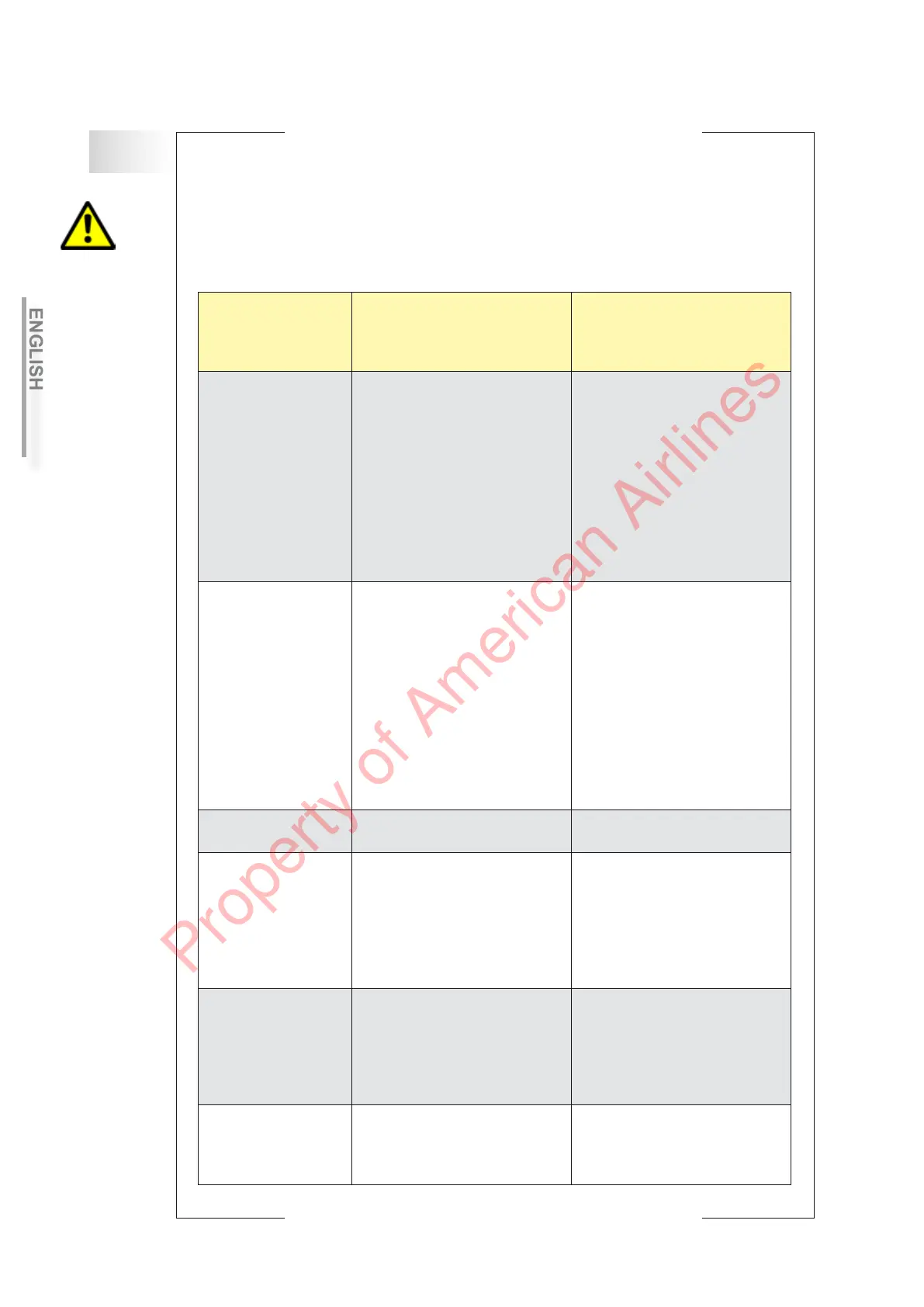

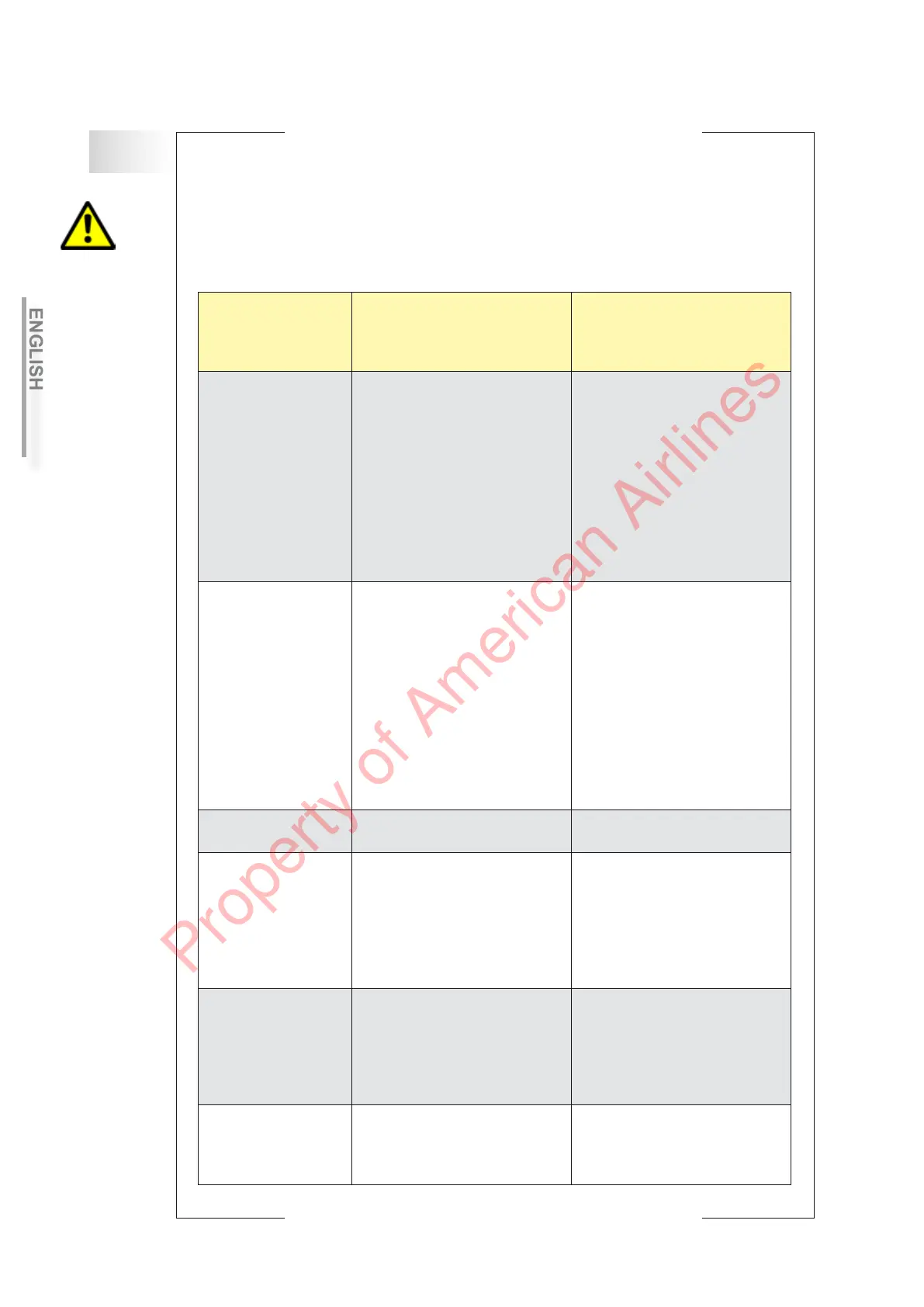

Error messages/

Faults

What do I do

if . . ?

Possible

causes . .

Remedy . .

...abnormal running

noises occur?

Damaged bearings•

Rotors coming into con-•

tact with one another or at

the conveying chamber

Rotors coming into con-•

tact due to soiling

Foreign bodies in •

gear wheels

Shaft deection•

Replace bearings•

Check play settings, •

check cylinder for cracks

Clean conveying chamber •

Check, clean and, if neces-•

sary, replace gear wheels

Measure shaft deection, •

replace rotary pistons if

necessary

...the compressor

becomes too hot?

Intake lter soiled•

Ambient temperature too •

high

Hood inlet openings •

blocked

Hood fan faulty•

Oil level or oil viscosity •

too high

Rotor play too great •

Overloaded•

Replace lter•

Ensure that there is ad-•

equate ventilation

Clean •

acoustic hood inlet

Replace fan•

Correct oil level, note the •

viscosity

Replace damaged com-•

ponents

Check and comply with •

operating data

...there is oil in the ma-

terial to be conveyed?

Oil level too high•

Worn seal•

Correct oil level•

Replace seals•

...the intake volume

is too low?

Starting strainer/intake •

lter soiled

Lines leaking•

Compressor incorrectly •

dimensioned

Damaged rotors/cylinder•

Clean, replace if neces-•

sary

Seal lines•

Check design •

Replace damaged com-•

ponents

...the motor takes

up too much power?

Operating data does not •

concur with ordering data

Mechanical damage to •

compressor or motor

Decline in motor voltage•

Check and comply with •

operating data

Replace damaged com-•

ponents

Adjust power; see motor •

instructions

...the compressor

turns in reverse

after

shutdown?

Non-return valve faulty or •

not tight

Replace valve•

Error diagnostics/Troubleshooting/Maintenance

Repairs to rotary piston machines may only be performed by authorised and

trained personnel. Improper repairs may present considerable risks to the user/

personnel.

Property of American Airlines

Loading...

Loading...