10

side of each hinge. Then, insert the hinges into the

wing. When all the hinges are in, working quickly,

coat the other end of the hinges with epoxy. Then,

join both fl aps. Do your best to wipe away any excess

epoxy. Move the fl aps up and down several times to

align all the hinges. Set the wing panels aside and

allow the epoxy to harden.

❏ 6. Join the outboard fl aps and ailerons to the outboard

wing panels the same way using fresh batches of

epoxy. Note that the ailerons use small hinges.

❏ 7. After the epoxy on all the hinges has hardened,

move the fl aps and ailerons up and down several

times to get them moving smoothly and easily.

We’ll install the servos and hook up the fl aps and

ailerons later.

MOUNT THE ENGINES

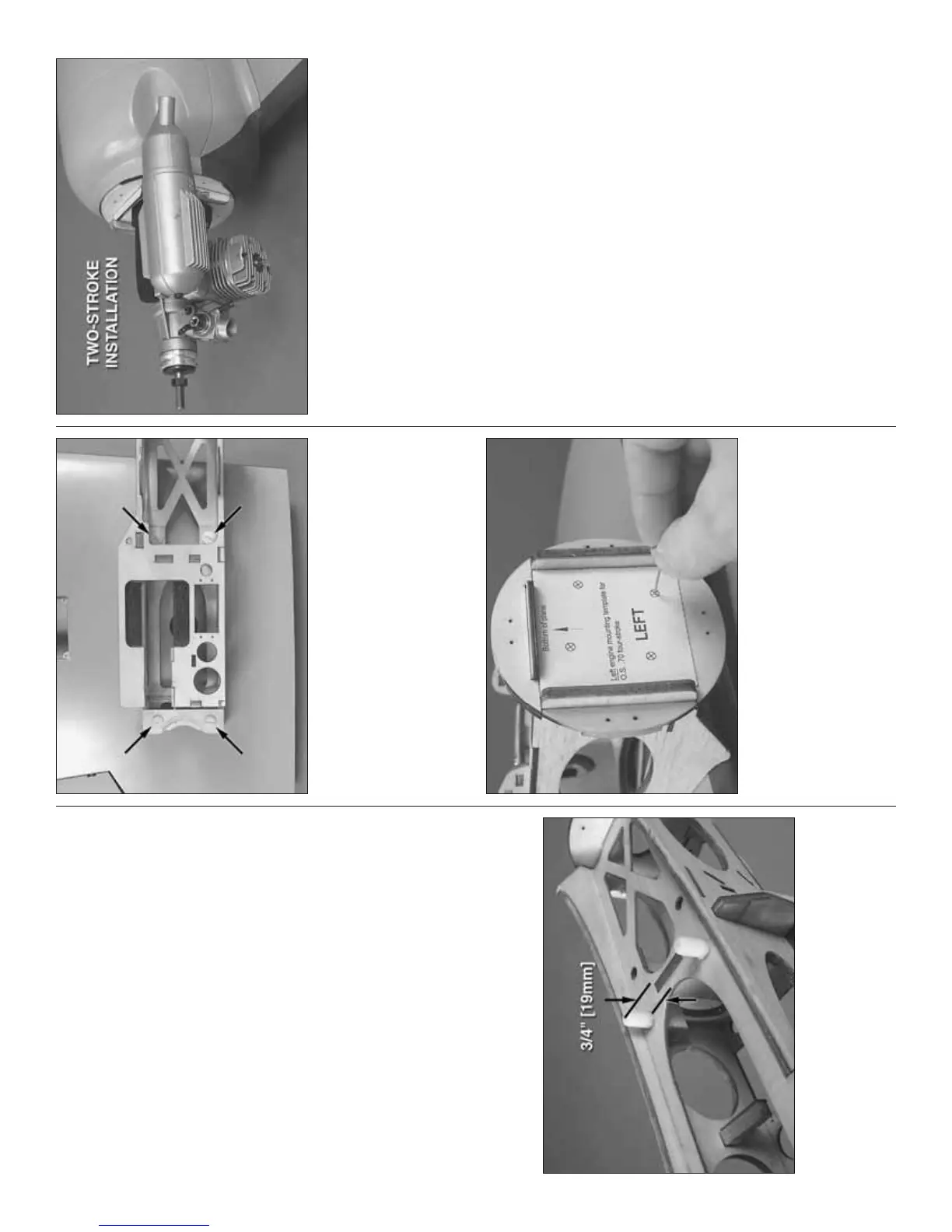

❏ 1. Use medium CA or epoxy to glue two 8 x 30mm

grooved nylon alignment pegs into the holes in

each engine nacelle. Be certain the peg indicated

protrudes above the base of the nacelle approximately

3/4" [19mm].

❏ ❏ 2. After the epoxy from the previous step has

hardened, use four 1/4-20 x 2" [50mm] nylon bolts

(indicated by the arrows in the photo) to mount the

left engine nacelle to the bottom of the left inboard

wing panel.

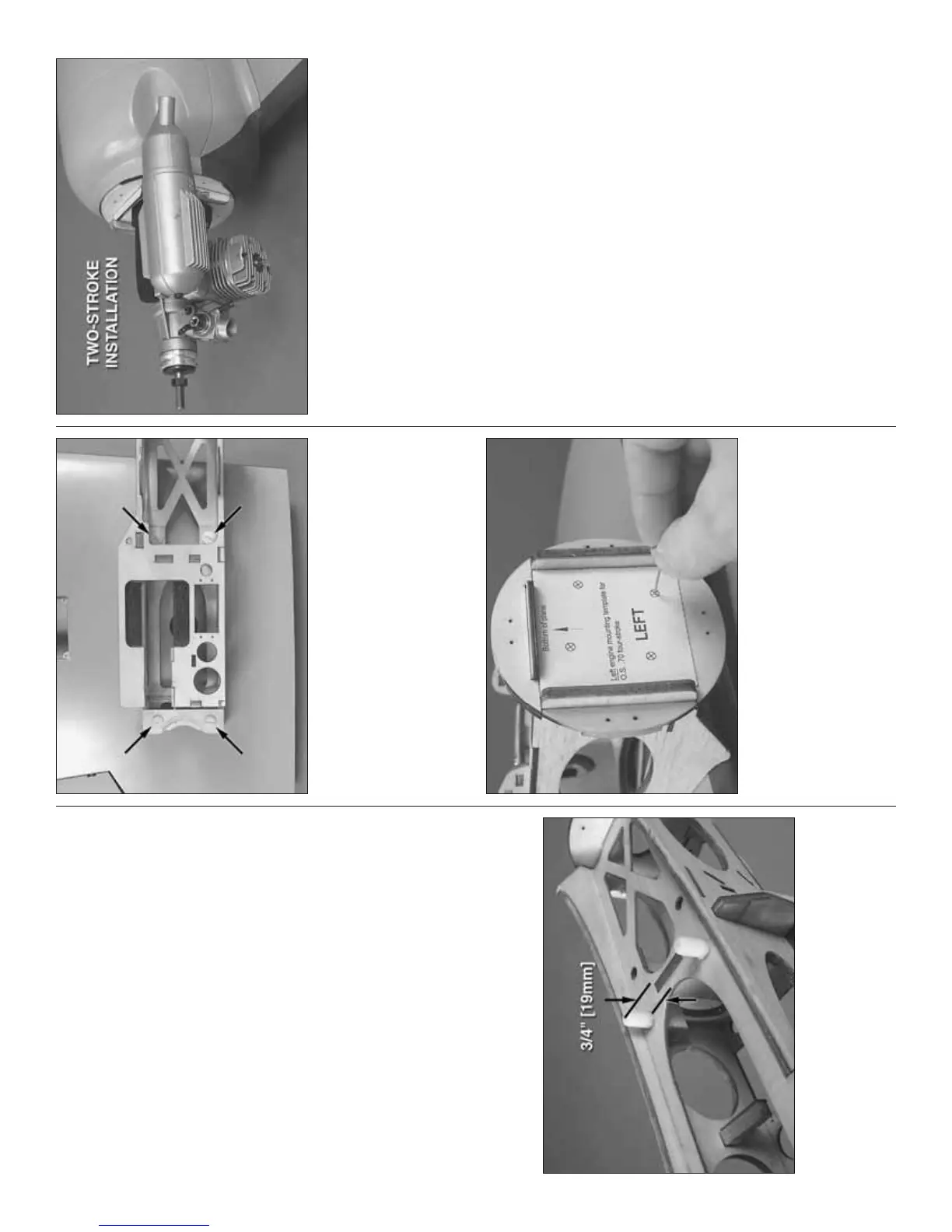

❏ ❏ 3. Read the note following this step. Then, cut

out the left Engine Mounting Template (since we’re

doing the left nacelle fi rst) from the back of the manual

for the type of engine you will be using—two-stroke

or four-stroke. Use tape or spray adhesive to hold the

template to the fi rewall. Then use a sharpened piece

of wire or a large T-pin to mark the center of the holes

in the template into the fi rewall.

Note: The four-stroke template is for the O.S. Max .70

Surpass and the two-stroke template is for an O.S.

Max .40 or .50 two-stroke. Since the engine mounts

are adjustable, they should fi t other engines in the

size range, but if you are using engines different than

O.S. the positioning of the mounts may have to be

rotated slightly to align the muffl er with the muffl er

cutout in the fi berglass nacelle cover. If this is the

case, you’ll have to mount your engine to the mount

before marking the holes in the fi rewall. Then, place

the nacelle cover over the nacelle on the wing panel

and position the mount (with the engine) so the

muffl er fi ts in the muffl er cutout.

❏ ❏ 4. Once the engine mount holes have been

marked, drill 5/32" [4mm] holes through the fi rewall

at each mark. Remove the template. Push 4-40 blind

nuts into the holes in the back of the fi rewall—if

necessary, trim away any plywood that interferes with

the blind nuts.

Loading...

Loading...