11

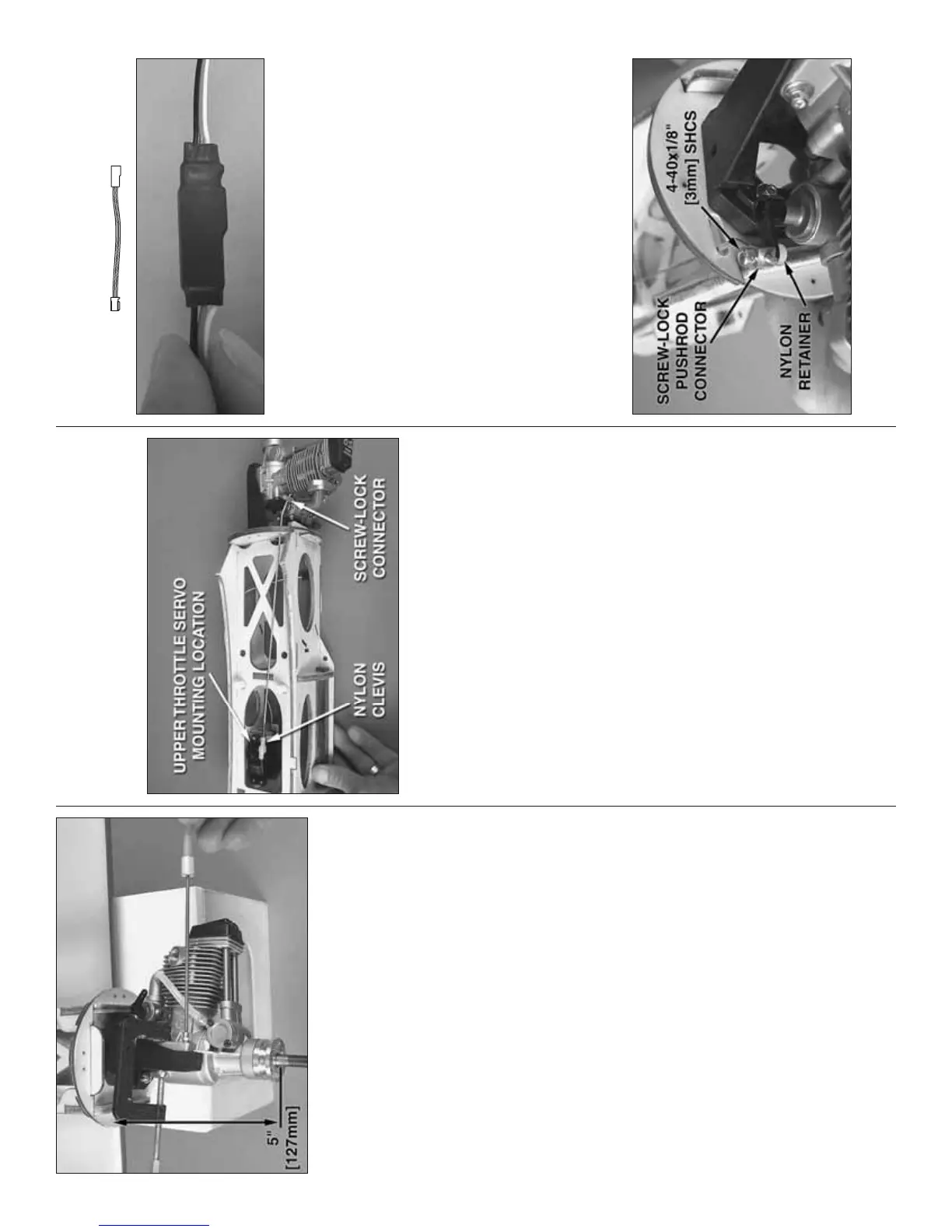

❏ ❏ 5. Loosely mount the engine mount to the fi rewall

with 4-40 x 3/4" [19mm] socket-head cap screws

(SHCS) and #4 fl at washers. Adjust the mount to fi t

your engine. Tighten the screws to pull the blind nuts all

the way into the back of the fi rewall. Temporarily clamp

the engine to the mount so the front of the drive washer

will be 5" [127mm] from fi rewall. Use a Dead Center

™

Engine Mount Hole Locator (GPMR8130) or another

method to mark the holes in the mount for the engine

mounting screws. NOTE: The 3/4" [19mm] screws

holding the mount to the fi rewall are intentionally short

so they do not cut into the front of the fuel tank. Later,

when mounting the engine for the fi nal time, you will

be instructed to add threadlocker to the threads of the

screws so they do not come loose.

❏ ❏ 6. Remove the engine from the mount and take

the mount off the fi rewall. Add a few drops of thin

CA to the edges of the blind nuts in the back of the

fi rewall so they won’t come out.

❏ ❏ 7. Drill #29 holes at the marks you made in the

engine mount halves for mounting the engine. Tap 4-

40 threads into the holes. Remount the mount to the

fi rewall and mount the engine to the mount with four

4-40 x 3/4" [19mm] SHCS, #4 lock washers and #4

fl at washers.

❏ 8. Mount the other engine to the right nacelle the

same way. Make sure you use the right engine mounting

template for marking the holes in the fi rewall.

HOOK UP THE THROTTLE AND

INSTALL THE FUEL TANK

Refer to this photo while hooking up the throttle.

The throttle servo may be mounted in either of two

locations depending on the location of the carburetor

arm on your engine. For most two-stroke engines, it

will be easiest to mount the throttle servo in the lower

location (the location in the bottom of the nacelle next

to the landing gear mount). For some four-stroke

engines (such as the O.S. Max .70 illustrated in this

manual), it will be easiest to mount the throttle in

the upper location (as shown in the photo). If using

the O.S. Max .70, the carburetor will also have to be

reversed to position the carburetor arm on the top.

If using the O.S. .70, remove the engine, reverse

the carburetor and carb arm, and then remount the

engine. However you decide to hook up the throttle,

make certain the pushrod will not interfere with the fuel

tank when it is in position later (you could temporarily

fi t the fuel tank while working on the throttle).

❏ ❏ 1. Center the throttle servo by temporarily

connecting it to the receiver with a battery and turning

on the radio with the throttle trim on the transmitter

centered. Cut off the unused servo arms so there is

one arm remaining.

6" [150 mm]

SERVO EXTENSION

❏ ❏ 2. Connect a 6" [150mm] servo extension to the

throttle servo. (There are diagrams on pages 48-49

that show all the servo extensions that were used.) Cut

a piece of the 3/8" x 3" [10 x 75mm] black heat shrink

tubing in half and fi t it over the connection between

the servo wire and the extension. Carefully shrink the

tubing with heat from a heat gun or a lighter.

❏ ❏ 3. Place the throttle servo in the mounting

location you will be using—if using the upper throttle

servo mounting location shown, the nacelle will have

to be removed from the wing. Use the mounting holes

in the servo as a guide to drill 1/16" [1.6mm] holes for

the servo mounting screws that came with the servo.

Temporarily mount the servo with the screws. Then,

remove the screws and servo. Add a few drops of

thin CA to each screw hole, allow to harden, and then

remount the servo.

❏ ❏ 4. Hook up throttle using a 2-56 x 17-1/2"

[445mm] pushrod and a nylon clevis on the servo

Loading...

Loading...