12

end and a brass screw-lock connector with a nylon

retainer and a 4-40 x 1/8" [3mm] socket-head cap

screw (SHCS) on the carburetor arm. Cut a slot in the

fi rewall for the throttle pushrod. Bend the pushrod as

necessary to connect to the carburetor arm.

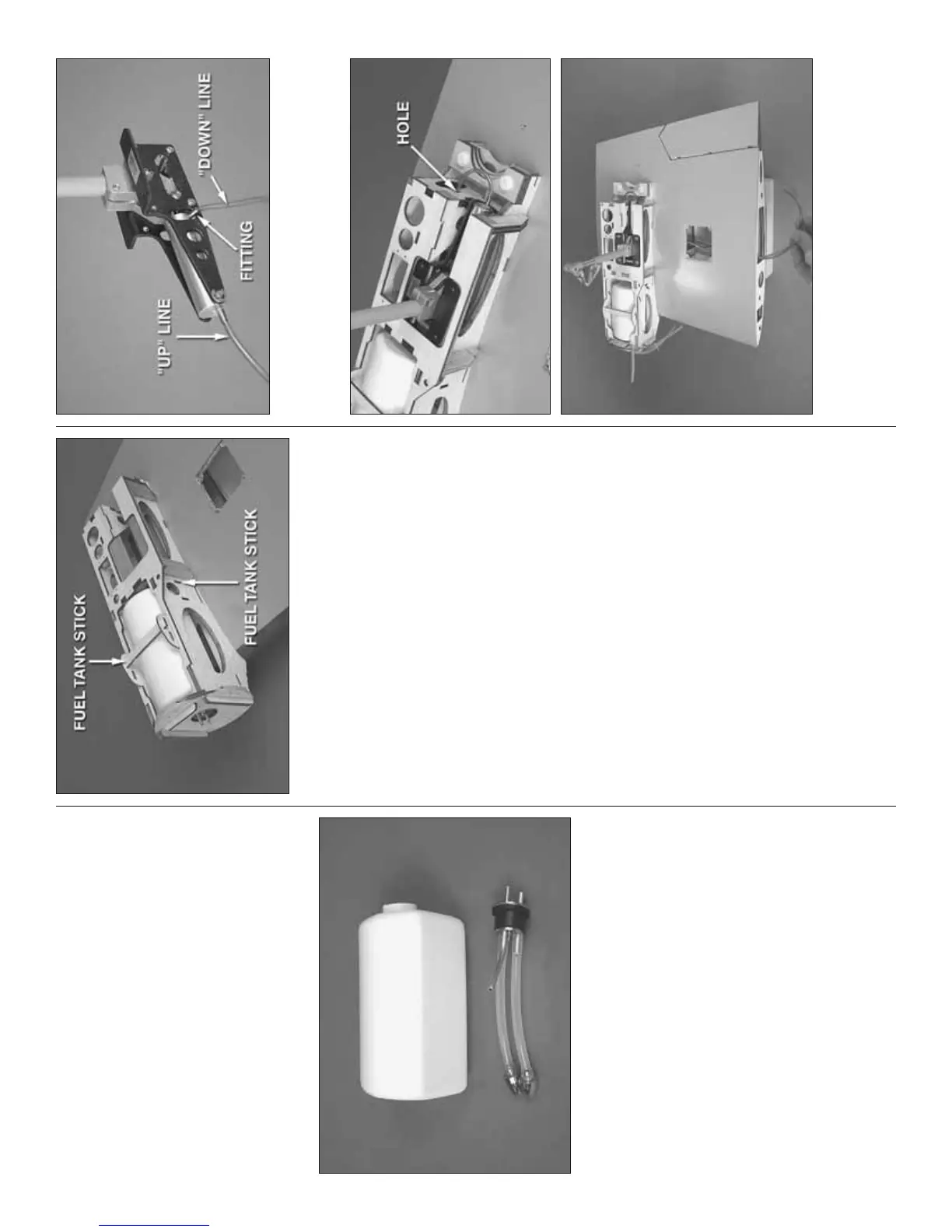

❏ ❏ 6. For installing the fuel tank, mounting the

fi berglass nacelle cover and mounting the landing

gear, it will be easier to have the engine out of the

way. Remove the engine mount from the fi rewall and

set the engine aside.

❏ ❏ 7. Assemble both fuel tanks—a three-line setup

is recommended—one for the vent/pressure line going

to the muffl er, one for fuel pickup to the carburetor and

a third line for fueling/defueling. This setup will allow

fueling and defueling without having to disconnect

any lines from the carburetor and without having to

turn the model upside-down. To set up the fuel tank

this way, cut two of the aluminum tubes to a length of

1-3/8" [35mm] and leave the other, longer tube as-is.

Assemble the stopper assembly with the aluminum

tubes, bend the longer vent tube upward so it will be

at the top of the tank, and then cut the silicone lines

to the correct length so the clunks will not contact the

rear of the tank. Connect the lines to the tubes in the

stopper and fi t the stopper into the tank and tighten

the screw. Make sure the clunks do not contact the

rear of the tank; otherwise, they could get stuck.

❏ ❏ 8. Mount the left nacelle to the wing with the nylon

bolts. Fit the fuel tank into the nacelle. Then, install and

glue two 3/8" x 3-1/16" [10 x 78mm] plywood fuel tank

sticks from the laser-cut plywood sheet into the slots

to hold the fuel tank in position. Note: Even though fuel

lines appear in a few of the following photos, there’s

no need to connect them until later after the cowl has

been mounted—the manual will instruct you later.

❏ 9. Return to step 1 and mount the engine, hook up

the throttle and install the fuel tank in the right nacelle

the same way.

MOUNT THE MAIN LANDING GEAR

RETRACT INSTALLATION

(If not mounting retracts, skip to “Fixed Gear

Installation” on the next page.)

Same as we’ve been doing so far, start with the left,

inboard wing panel.

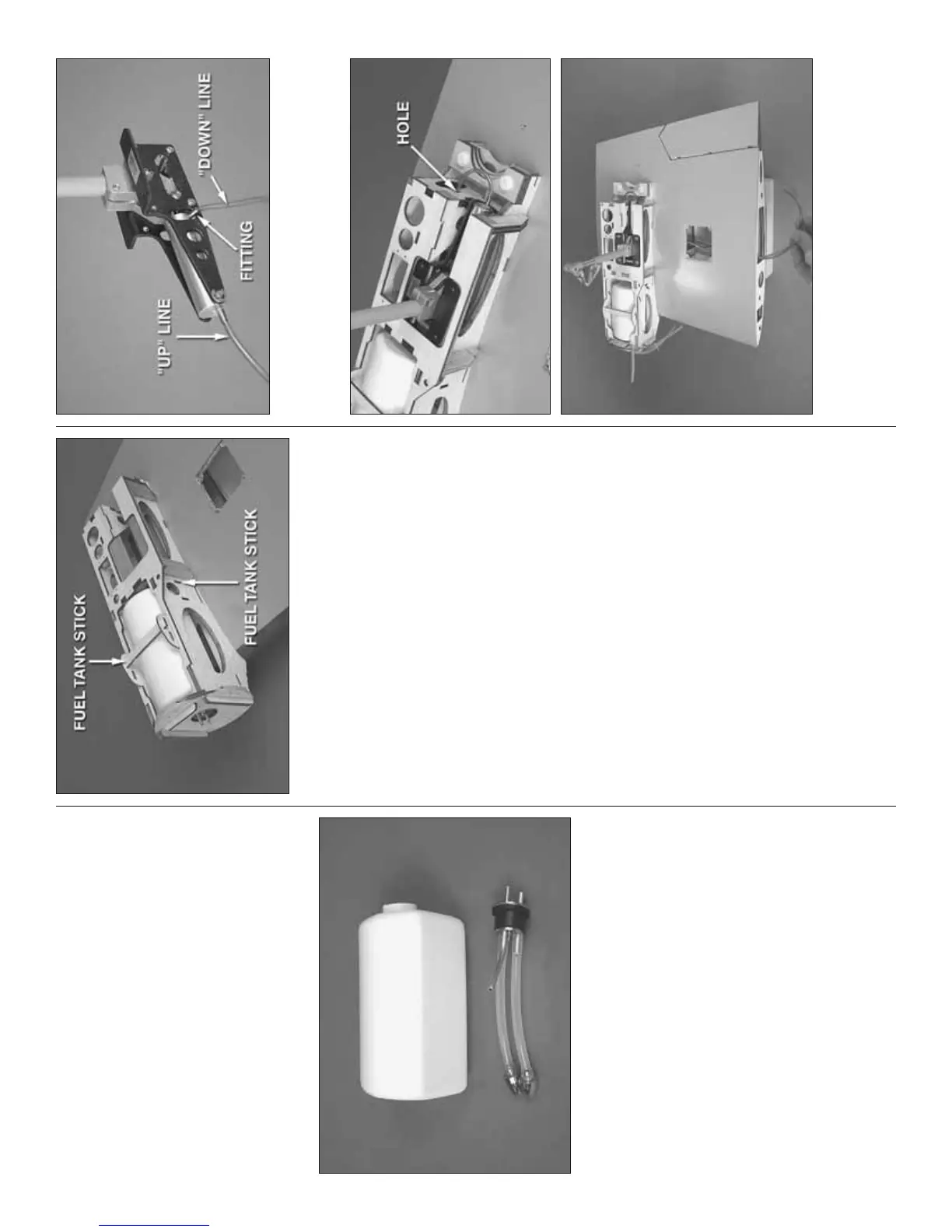

❏ ❏ 1. Determine which color of air line you will be

using for the “up” line and which color you will be

using for the “down” line—the up line connects to the

fi tting on the back end of the air cylinder and the down

line connects to the fi tting on the front of the cylinder

that comes out of the side. Cut the up line to a length

of 21" [530mm] and cut the down line to a length of

18" [460mm].

❏ ❏ 2. Connect the lines to the air cylinder. Rotate

the fi tting on the down line as shown so it will be

easier to fi t the gear between the rails.

❏ ❏ 3. Install the retract and guide the air lines through

the hole in the bottom of the panel, past the fl ap servo

hatch and out root end of the panel—note that the up line

goes through the hole in the back of the nacelle fi rst.

Loading...

Loading...