20

❏ ❏ 8. Mount the cowl ring to the cowl mounting

tabs with four 4-40 x 1/2" SHCS, #4 lock washers and

#4 fl at washers. Note that the top screw goes in from

the front, but the other three go in through the back. A

3/32" ball end hex wrench (GPMR8002) is virtually a

must from here on out. Once the cowl ring has been

fastened to all the tabs, go ahead and tighten up the

screws holding the tabs to the fi rewall.

❏ ❏ 9. Mount the engine mount and engine without

the muffl er. Trim the cowl ring as necessary until you

can get the muffl er to fi t.

❏ ❏ 10. Remove the muffl er from the engine. Get

ready to start cutting fi berglass and read the Hot Tip

below that lists recommended tools, working tips and

safety warnings for cutting fi berglass.

Tools For Cutting Fiberglass

There are several fi berglass parts on this model. A

few of them will require cutting and trimming to end up

with the best fi t. Follow these warnings and use the

suggested tools for working safely with fi berglass.

A. Do not be casual when working with fi berglass.

Always wear eye and respiratory protection.

B. Work in a well-ventilated area—working under an

exhaust fan that will draw fi berglass dust away is

best. If possible, cutting fi berglass outdoors may

also be a good idea.

C. Wear a long-sleeve shirt when cutting fi berglass.

D. If using a high-speed rotary tool, hearing

protection is recommended.

E. Following are the best tools for cutting fi berglass:

I. A rotary tool.

II. A fi ne-point, felt-tip pen for marking. (Afterward,

ink can be removed with a paper towel and

denatured alcohol.)

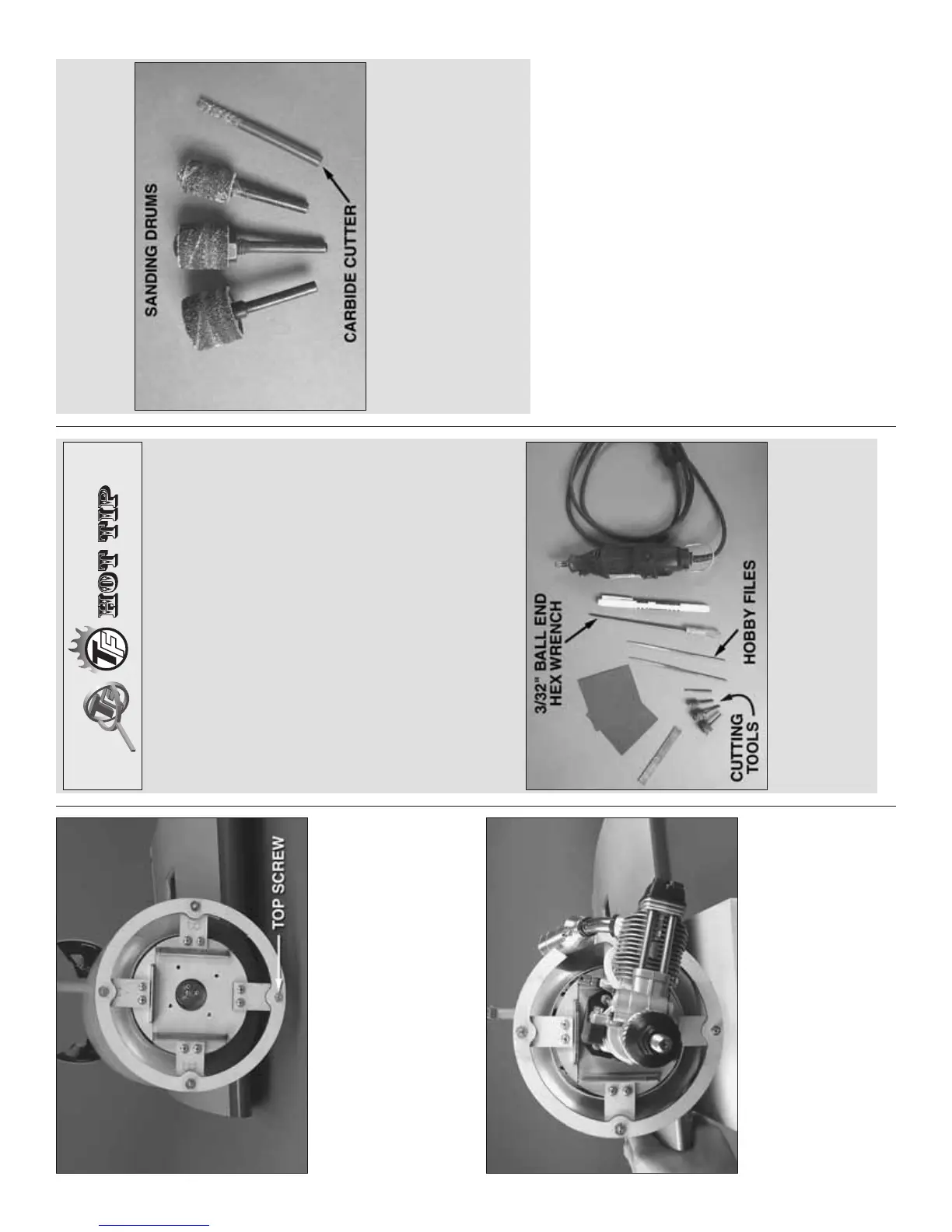

III. A 3/32" ball driver will be indispensable when

fi tting the cowl later.

IV. Curved and fl at hobby fi les.

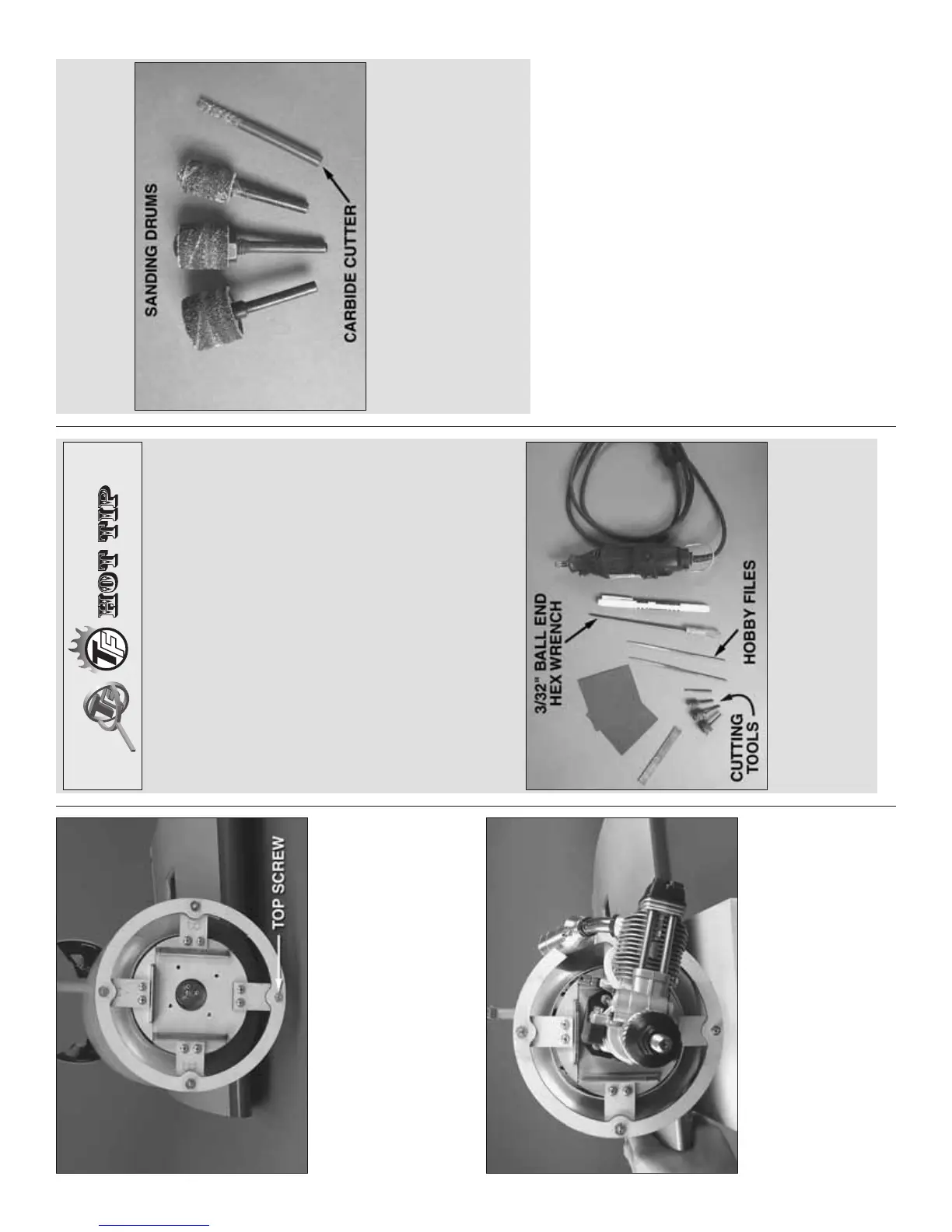

V. Various cutting bits for your rotary tool—the

carbide cutter is best for making initial cuts.

Abrasive drum sanders work well for “fi ne-

tuning.”

VI. A small sanding board made from a piece of

plywood with sandpaper glued on.

VII. Small sheets of medium-grit sandpaper to

smooth rough edges.

❏ ❏ 11. Retrieve your fi berglass cutting tools and

safety equipment. Cut one of the fi berglass engine

cowls to fi t over the engine—it doesn’t matter which

of the two cowls you choose because they are both

the same. Cutting the hole is basically a trial-and-error

process where you cut-and-fi t and cut-and-fi t the cowl

until it goes over the engine. If using a 4-stroke, the

cowl fi tting procedure will be easier if the valve cover

is temporarily removed. If using a 2-stroke the cowl

will be easier to fi t if the head is temporarily removed.

This will allow the cowl to fi t without having to fi nalize

the exact size, shape and location of the cutout until

after the cowl has been permanently mounted. Start

by trying to fi t the cowl over the engine as far as it

will go. Use a fi ne-point felt-tip pen or a lead pencil

to mark the inside of the cowl in the approximate

location where the engine will stick out.

Loading...

Loading...