24

How to Solder

A. Use denatured alcohol or other solvent to

thoroughly clean the pushrod. If necessary, cut

the pushrod wire to the correct length. Roughen

the end of the pushrod with coarse sandpaper

where it is to be soldered.

B. Apply a few drops of soldering fl ux to the end of

the pushrod. Then, use a soldering iron or a torch

to heat it. “Tin” the heated area with silver solder

(GPMR8070) by applying the solder to the end.

The heat of the pushrod should melt the solder—

not the fl ame of the torch or soldering iron—thus

allowing the solder to fl ow. The end of the wire

should be coated with solder all the way around.

C. Place the clevis on the end of the pushrod. Add

another drop of fl ux, and then heat and add

solder. The same as before, the heat of the

parts being soldered should melt the solder,

thus allowing it to fl ow. Allow the joint to cool

naturally without disturbing. Avoid excess

blobs, but make certain the joint is thoroughly

soldered. The solder should be shiny, not rough.

If necessary, reheat the joint and allow to cool.

D. Immediately after the solder has solidifi ed, but

while it is still hot, use a cloth to quickly wipe off

the fl ux before it hardens. Important: After the

joint cools, coat with oil to prevent rust. Note:

Do not use the acid fl ux that comes with silver

solder for electrical soldering.

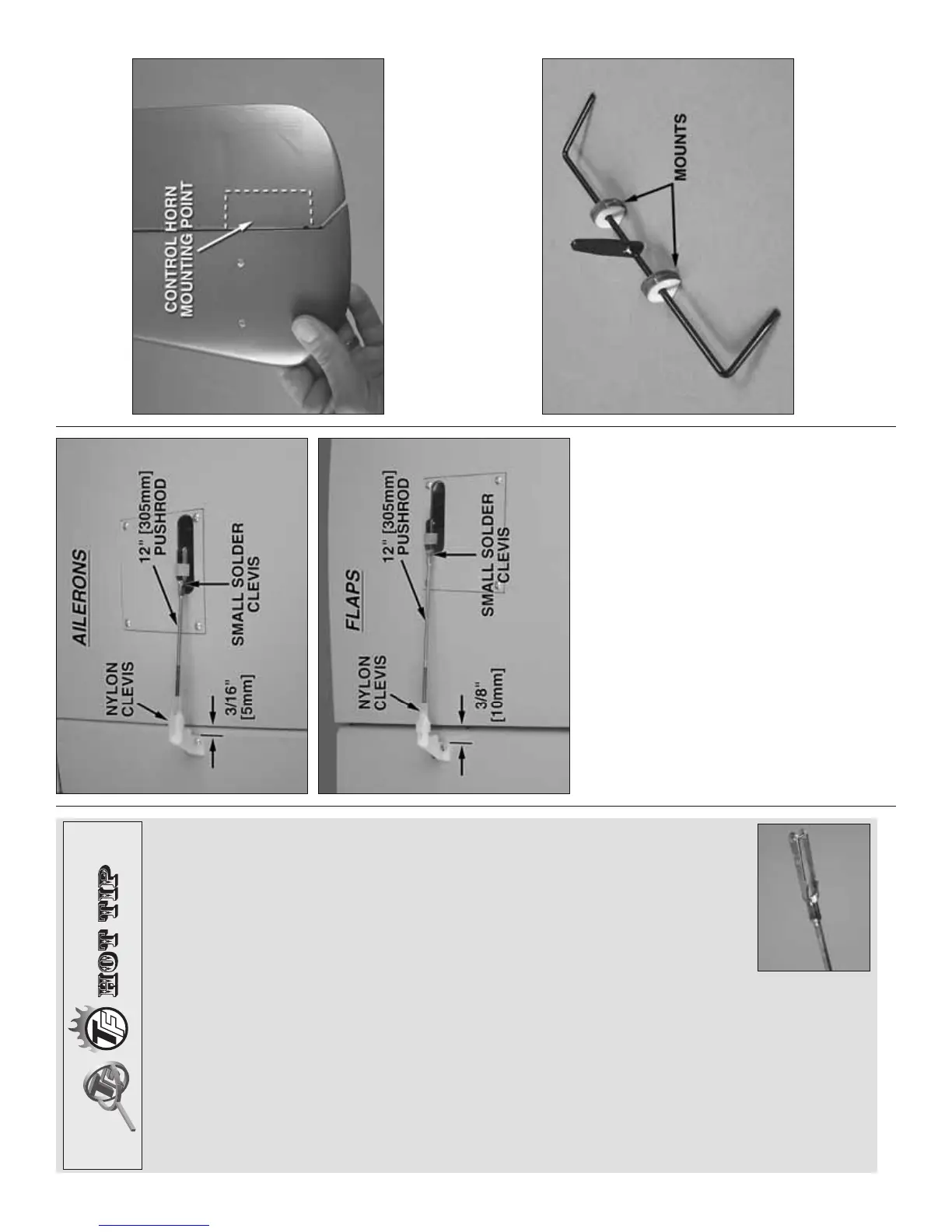

This is what a properly

soldered clevis looks like—

shiny solder with good fl ow,

no blobs, fl ux removed.

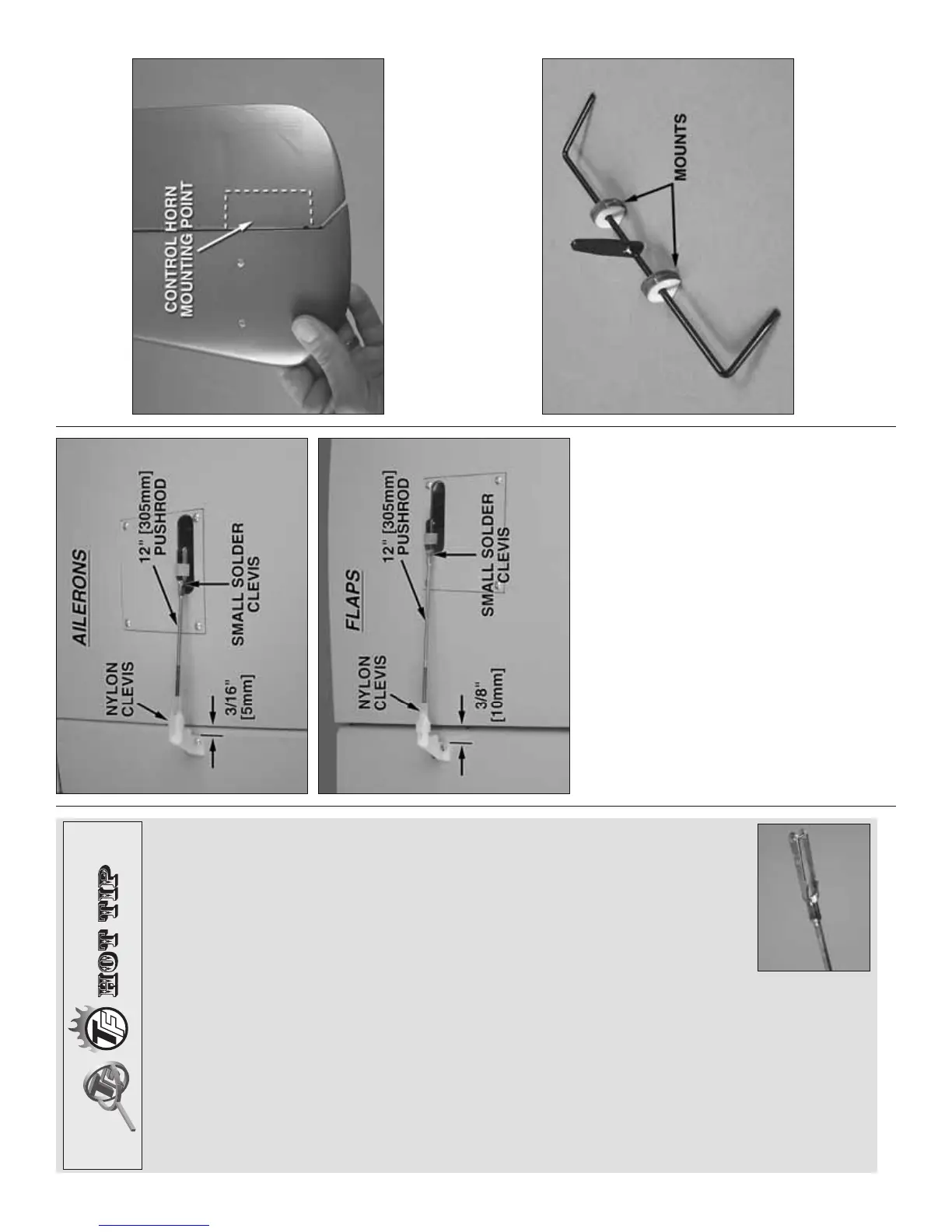

❏ 6. Hook up the fl aps and ailerons using the

hardware shown. For the fl aps, note that when the

fl aps are fully retracted (“up”) the servo arms should

be back and when the fl aps are extended the servo

arms should be forward. Also note that the front edge

of the fl ap control horns is set back 3/8" [10mm] from

the TE of the wing and the front edge of the aileron

control horns is 3/16" [5mm] from the TE of the

wing. Drill 1/16" [1.6mm] holes for the control horn

mounting screws. Mount the horns with #2 x 3/8"

[9.5mm] Phillips screws and mount the hatches with

#2 x 3/8" button-head Allen screws. After installing

all the wood screws, temporarily remove the screws,

add a few drops of thin CA to each hole, allow the CA

to harden and then reinstall all the screws.

ASSEMBLE THE TAIL

HINGE THE ELEVATORS AND RUDDERS

❏ 1. Use 30-minute epoxy to hinge the rudders to the

vertical stabilizers. Be certain the mounting points in

the rudders for mounting the control horns are on the

bottom and also make sure the rudders aren’t pushed

too close up to the vertical stabilizers. Otherwise,

control throw may be limited. Set the rudders aside

while working on the elevators.

❏ 2. Use coarse sandpaper to roughen the torque

arm portions of the elevator joiner wire so glue will

adhere. Slide two plywood elevator joiner mounts

over both ends of the elevator joiner wire. Then, glue

the two sets of mounts together.

Loading...

Loading...