23

the pushrods into the holes. Then, use medium CA to

glue the pushrods in.

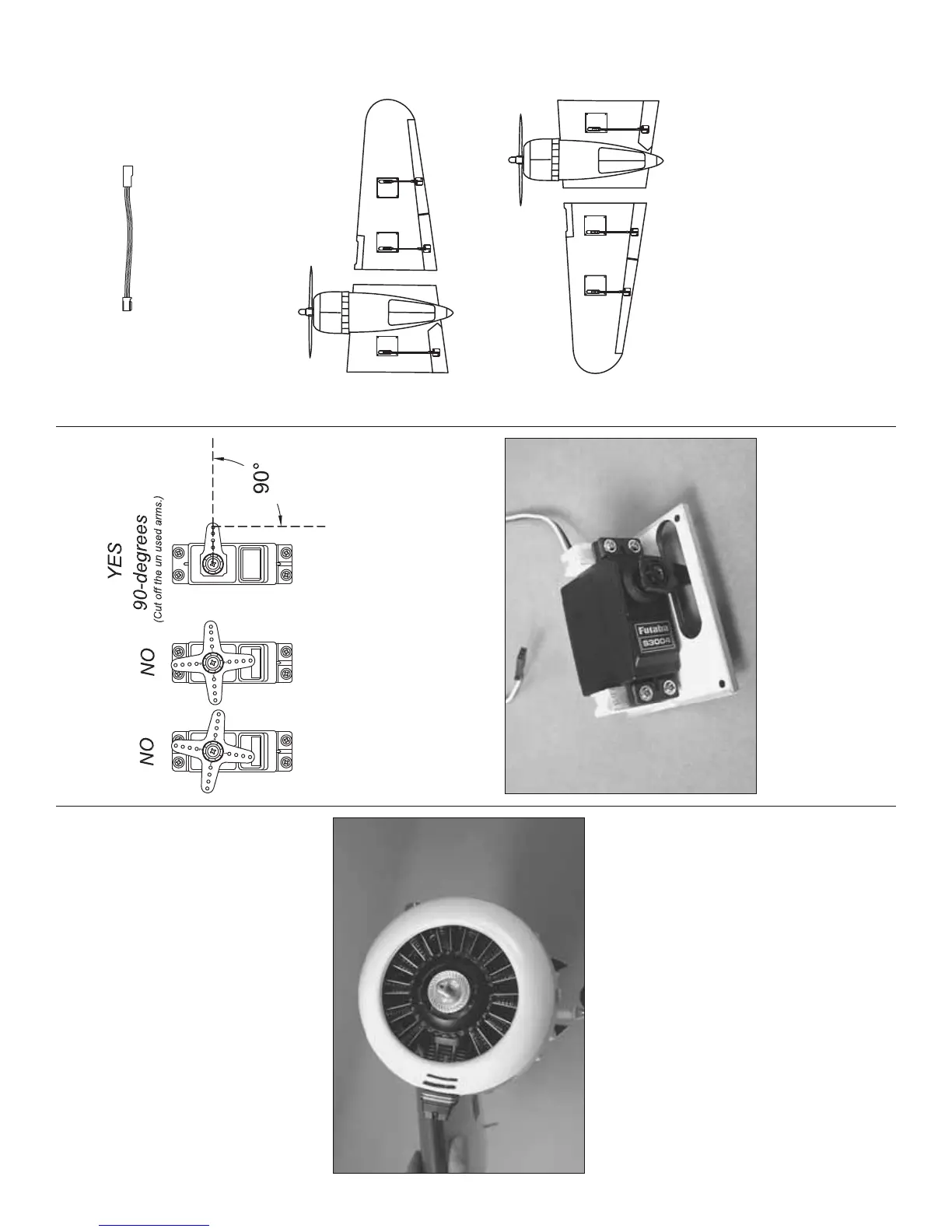

❏ ❏ 4. Fit the replica engine in the cowl and align the

two missing cylinders with the cutout for the engine.

Level the replica engine inside the front of the cowl,

double-check the alignment, and then use thin CA

to carefully glue the replica engine into position. Use

care not to use too much CA which could run onto the

outside of the cowl.

❏ ❏ 5. If necessary, cut a hole in the top of the

replica engine in alignment with the slot in the top of

the cowl for the 3/32" Allen wrench.

❏ ❏ 6. Take the drive washer off the engine. If

necessary, enlarge the hole in the front of the replica

engine so the cowl will go over the engine. Mount

the cowl to the nacelle and put the drive washer

back on. If you prefer not to remove the drive washer

for installing the cowl, the hole in the middle of the

replica engine will have to be enlarged even more.

Similarly, if you install the valve cover on the engine

after you install the cowl, the hole in the cowl for the

engine can remain small.

❏ 7. Mount the other replica engine in the other cowl

the same way.

HOOK UP THE FLAPS AND AILERONS

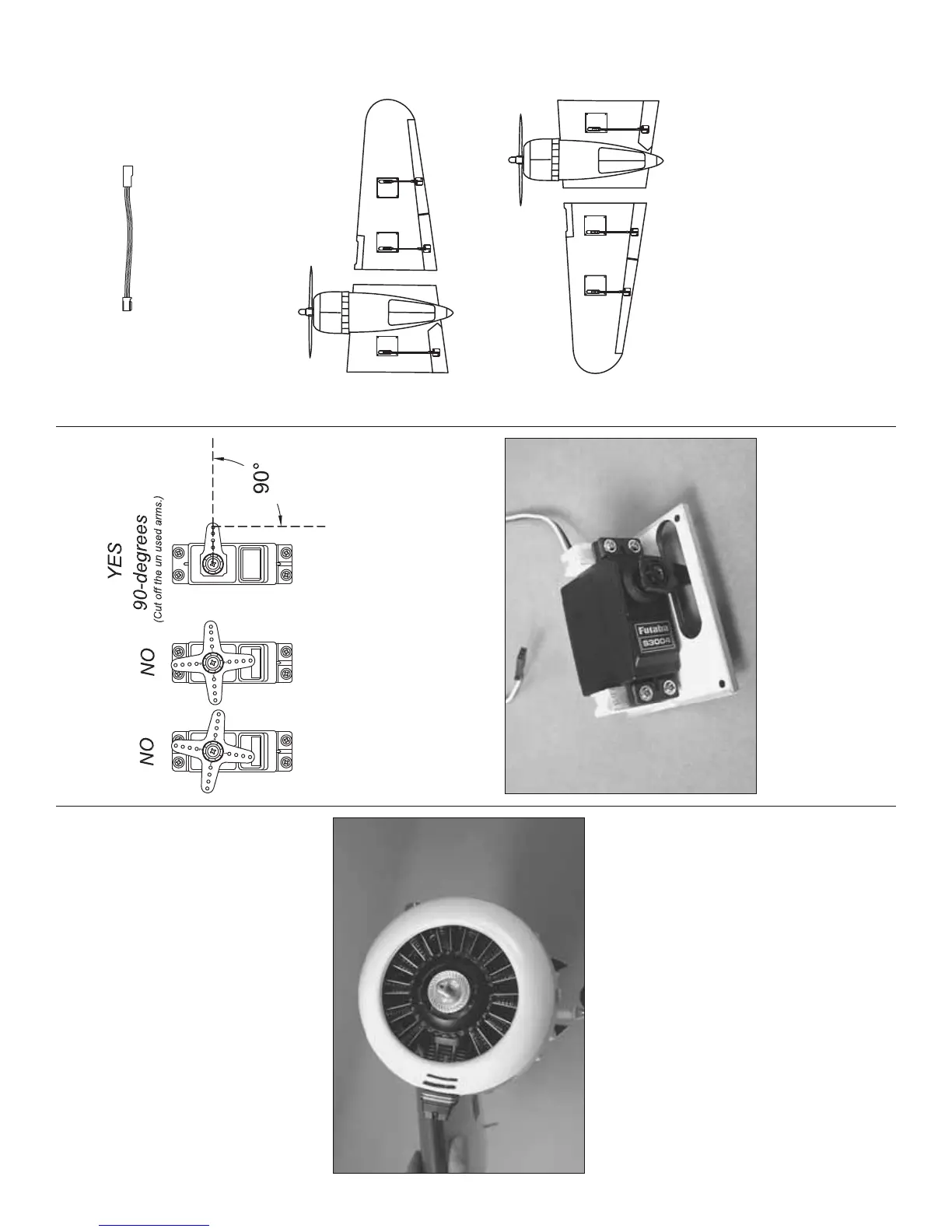

❏ 1. Retrieve your fl ap and aileron servos. Center

each servo by connecting it to the receiver, centering

the trims on the transmitter, and then turning on the

transmitter and receiver. Once you fi nd the servo arm

that’s 90-degrees, cut off the rest.

❏ 2. Mount the servos to the mounting blocks on each

of the six hatches by using the holes in the servos as

guides for drilling 1/16" [1.6mm] holes into the servo

blocks. Temporarily mount the servos with the screws

that came with them, remove the screws and servos,

and then harden each hole with a few drops of thin CA.

Allow the CA to harden. Then, remount the servos.

6" [150 mm]

SERVO EXTENSION

❏ 3. Connect a 6" [150mm] servo extension to

each aileron servo. (Refer to the “Servo Extensions”

sketches in the back of the manual for full diagrams

of what servo extensions and Y-harnesses are used.)

Same as the throttle servos, secure the connection

with 1-1/2" [40mm] pieces of heat shrink tubing.

The hatches have been

enlarged for clarity.

LEFT WING

RIGHT WING

❏ 4. Noting the orientation of the servo hatches in the

bottom of the wing, place the servo hatches with the

servos in the respective wing panels—be certain the

screws that hold on the servo arms are in all the servos!

Use the strings in the wings to guide the servo wires

out the ends of the panels—or just drop them down

through the holes while holding the wings on-end.

❏ 5. Prepare for making the fl ap and aileron pushrods

by reading the following “Hot Tip” on how to solder.

Then, gather your soldering equipment.

Loading...

Loading...