22

Now it’s time to fi nalize the engine cutout and

make the cutout for the muffl er.

❏ ❏ 21. Mount the muffl er to the engine. Repeat

the cut-and-fi t procedure to cut out the cowl for the

muffl er. Proceed slowly, cutting a little at a time and

test fi tting the cowl often as you proceed.

❏ ❏ 22. Now that the cowl has been rough-cut to

fi t around the engine and muffl er, use a rotary tool

with a sanding drum to make any fi nal cuts so there

will be adequate clearance around the engine and

muffl er and so the cutouts look good with smooth

lines, straight edges and nicely-rounded corners. You

can also make additional cutouts for cooling air where

necessary. Final-sand all the openings with 320-grit

or 400-grit sandpaper.

❏ ❏ 23. Cut any other holes necessary for the needle

valve, low-speed needle adjustment screw, glow plug

igniter, fuel fi lling, etc.

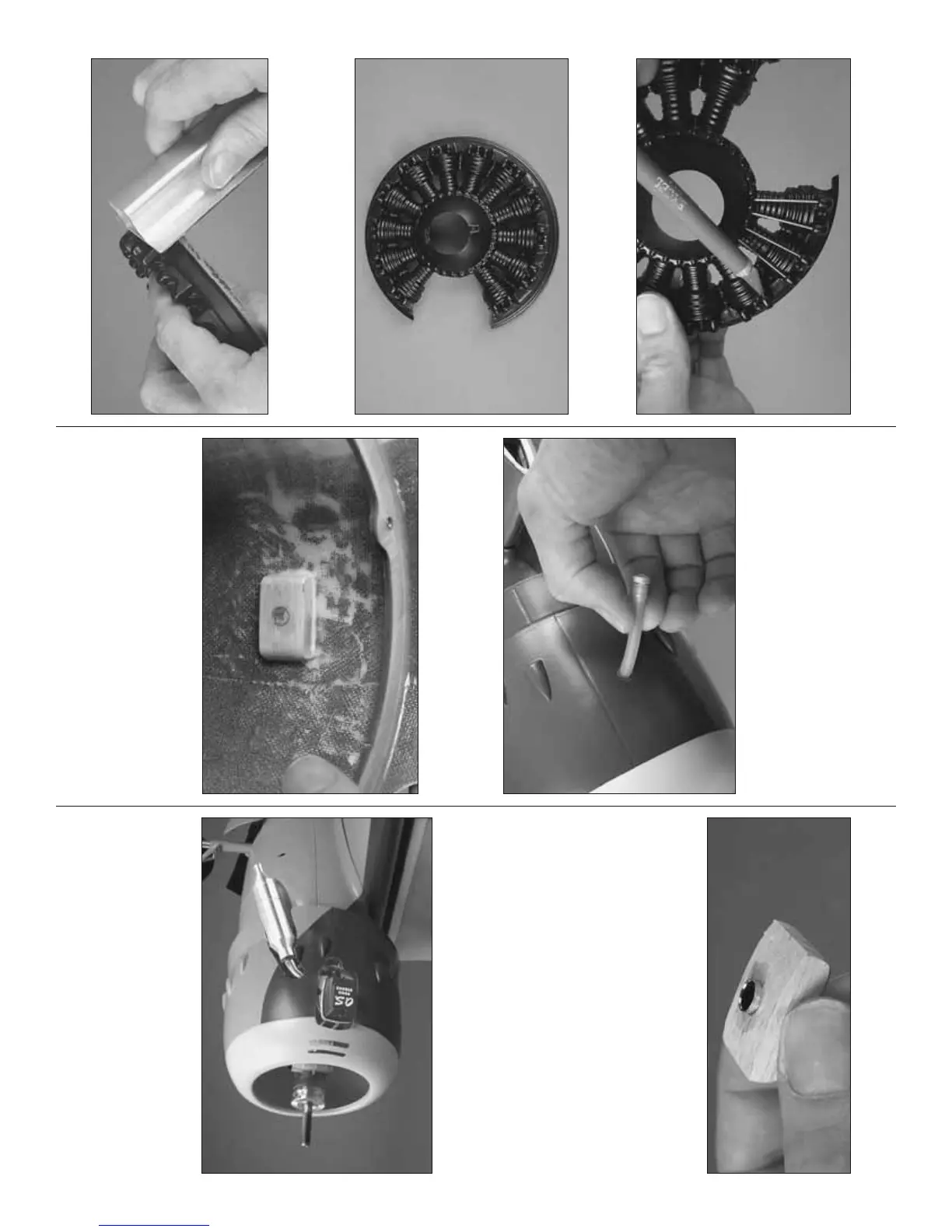

❏ ❏ 24. To duplicate the fueling system shown in this

manual, make a fuel line mount for the fuel fi lling line

from a balsa block (not supplied) and a 9/32" [7mm]

O.D. K+S brass tube. Sharpen the end of the tube,

and then use it to cut a hole through the balsa block.

Round the top of the block to fi t the inside of the cowl.

Glue a 1/4" [6mm] piece of the brass tube into the

balsa block so it sticks out the rounded side of the

block 1/32" [.5mm].

❏ ❏ 25. Cut a 9/32" [7mm] hole in the cowl where you

want the fueling line to come out. Use epoxy mixed

with microballoons to glue the block into position.

❏ ❏ 26. Connect 8" [200mm] of silicone fuel tubing

(not included) to the fi ll line coming from the fuel tank.

When mounting the cowl later, guide the fi lling line

through the brass tube in the cowl. After fueling the

model at the fi eld, close the line with an aluminum

fuel line plug. Then, push the line back into the tube.

❏ 27. Mount the right cowl the same way.

MOUNT THE REPLICA ENGINE

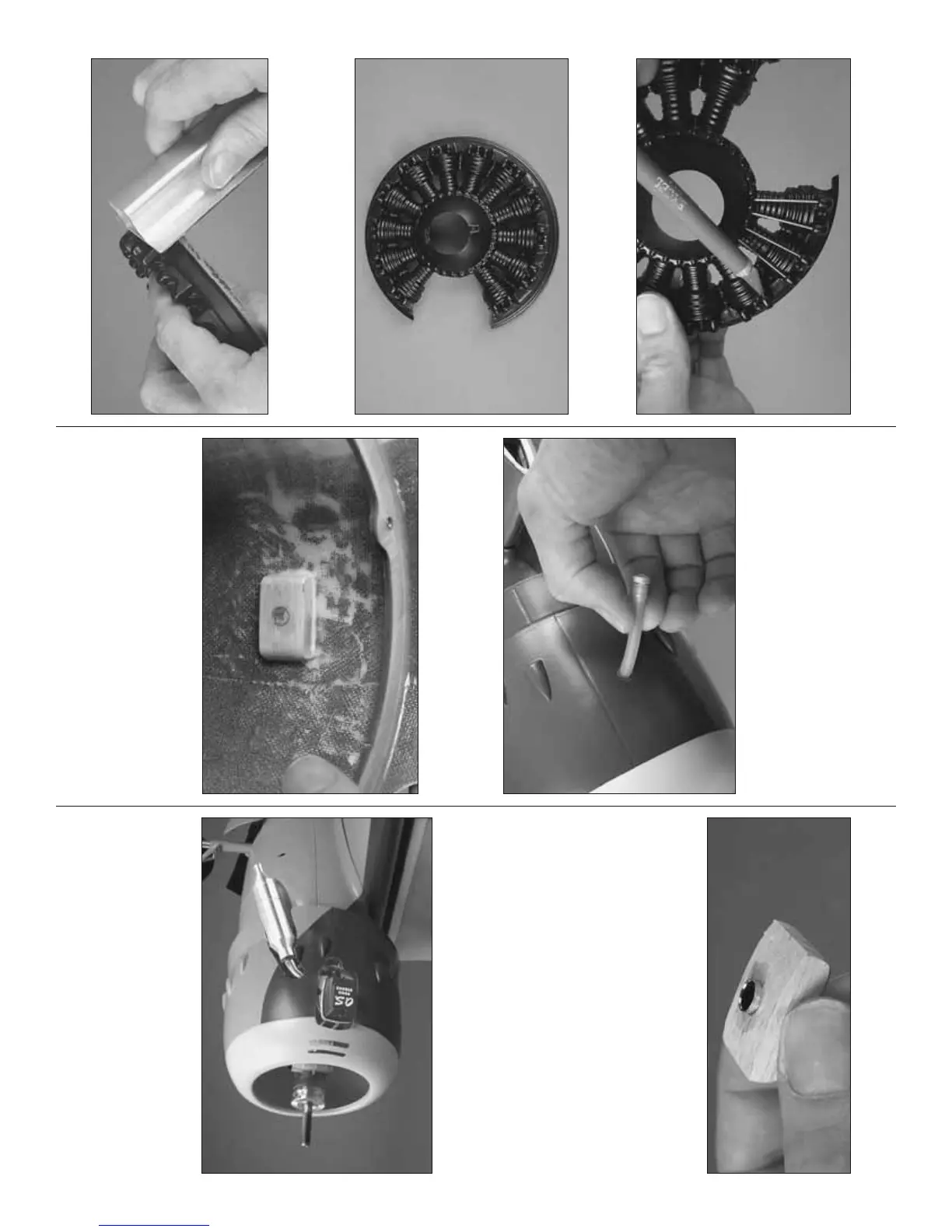

❏ ❏ 1. Sand all the way around the edge of one of the

replica engines so glue will adhere. Sand the inside of

the cowl where the engine will be glued as well.

❏ ❏ 2. Use curved-tip plastic-cutting scissors or your

rotary tool to cut out two cylinders of the replica engine.

❏ ❏ 3. Carefully twist a hobby knife into the plastic

making small holes for the wire replica pushrods. Fit

Loading...

Loading...