Part No.

Part Designation

Part No.

Part Designation

Part No.

Part Designation

1060

Suction casing

4120.2

O-ring

9021

Gland bolt

1070

Discharge casing

4520

Stuffing box gland

9050

Tie bolt

1080

Stage casing

4580

Lantern ring

9200.1

Hex. nut

1711

Final stage diffuser

4610

Stuffing box packing

9200.2

Hex. nut

2100

Shaft

5040.1

Spacer ring

9201

Threaded plug

2300

Impeller

5040.2

Spacer ring

9320.1

Circlip

3210

Deep groove ball bearing

5070

Thrower

9320.2

Circlip

3500

Bearing housing

5240

Shaft protecting sleeve

9400.1

Key

3600

Bearing cover

5251.1

Spacer sleeve

9400.2

Key

3610

Bearing end cover

9010

Hex. head bolt

9400.3

Key

4120.1

0-ring

9020

Stud

9400.4

Key

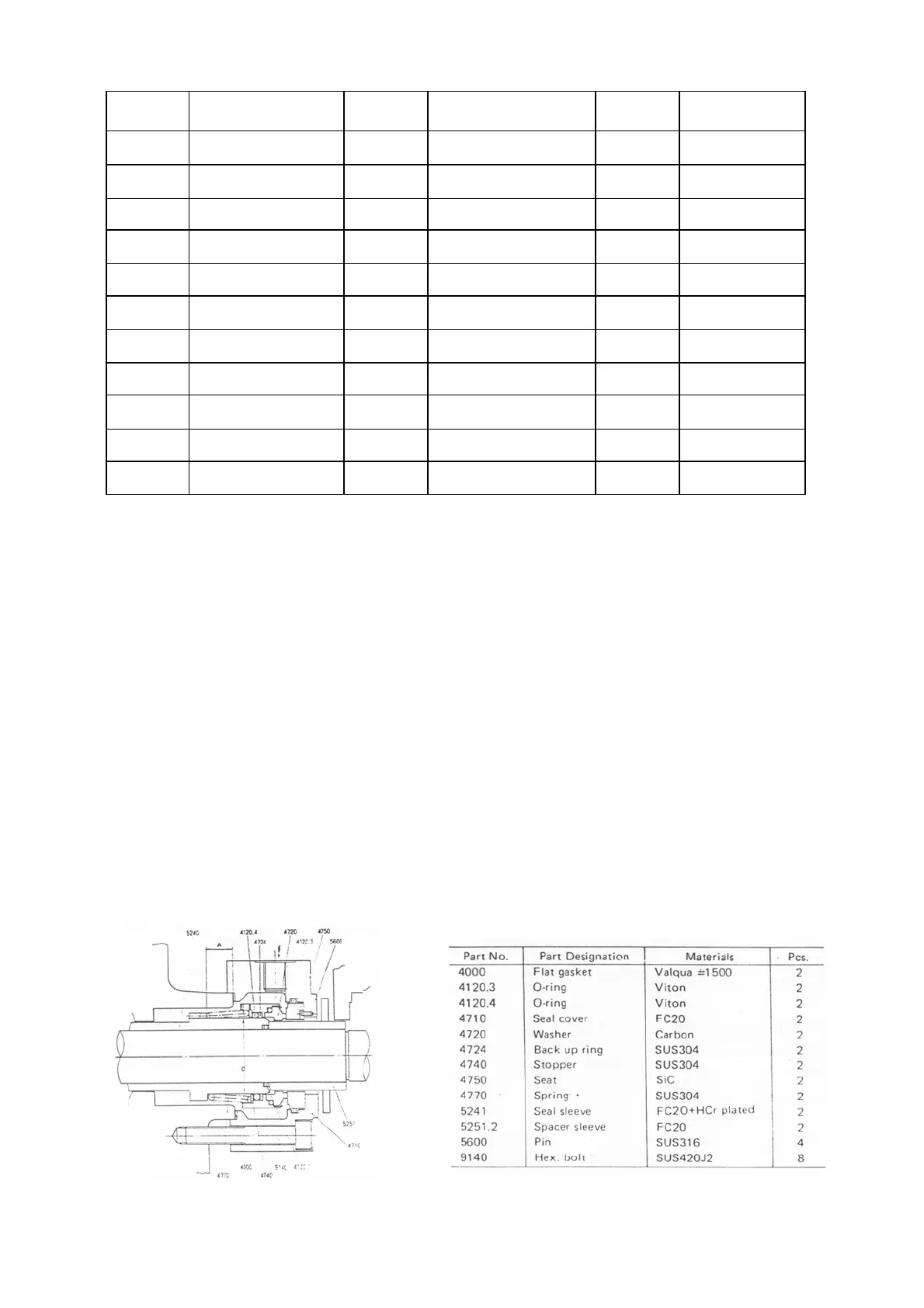

4. Mechanical Seal

4. 1. General Caution

(1) The mechanical seal service life is significantly shortened by impurities if included therein. Therefore,

clean the mechanical seal and the pump internals when reassembling and prevent invasion of such

impurities into the mechanical seal from the flushing line during pump running.

(2) Absolutely avoid dry-running (including the running at seal chamber pressure less than the atmospheric

pressure). Dry-running would cause seizure and damage of the mechanical seal and occasional damage

of the pump.

(3) The sliding end face of the mechanical seal is finished very accurately by lapping. So, it must be handled

with good care neither to flaw nor break the sliding end face.

(4) Once overhauled, replace the sliding end face of the mechanical seal with new one or repair it by lapping

as a rule.

4. 2. Construction

Fig. 7 Illustrates the mechanical seal construction. Fig. 7 Construction of Mechanical Seal

Loading...

Loading...