(a) Apply oil coating in small quantity to O-ring ( 4120. 4 ).

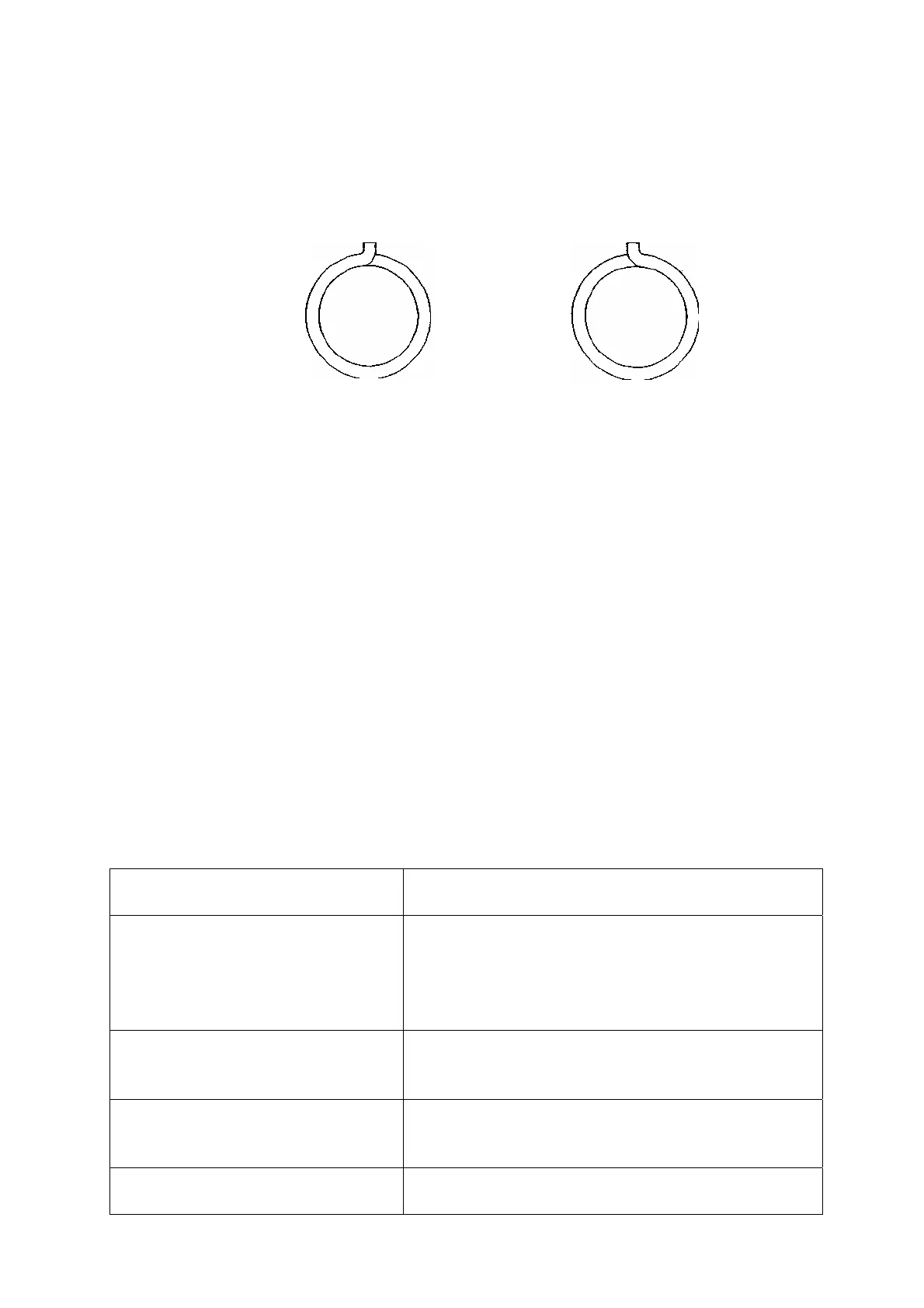

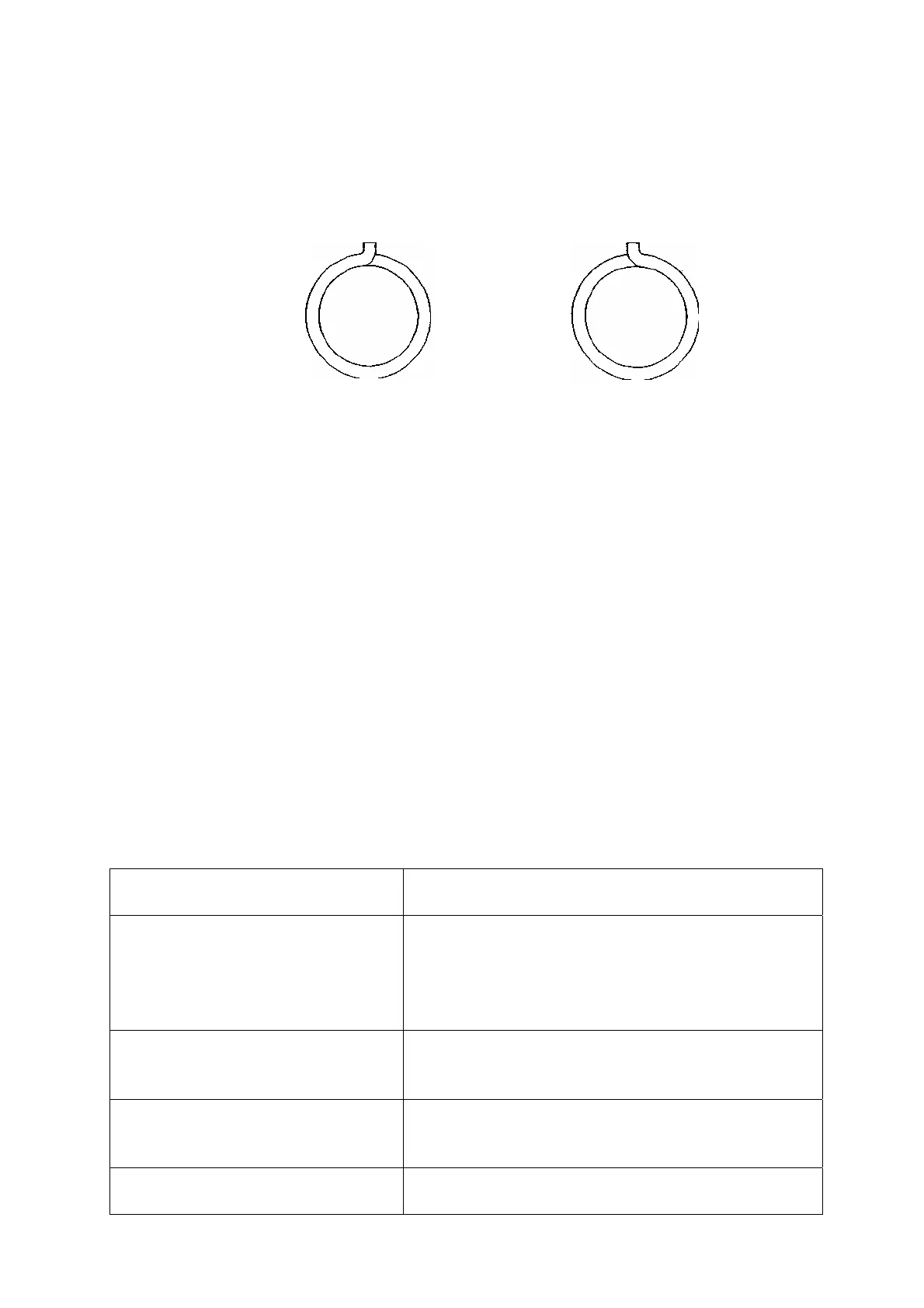

(b) Pay attention to the coiling direction of spring ( 4770 ). Viewing from the suction side, the right-

hand coiled spring is for the suction side use and the left hand coiled one for the discharge side

use. ( Refer to Fig. 9 ) Reverse fitting of these springs would cause them to break during the pump

running. Therefore, fit them at the specified side without fail.

Right-hand coiled spring Left-hand coiled spring

Fig. 9

(3) Insert seal sleeve ( 5240 ) in the shaft and then insert O-ring ( 4120. 1 ) in the seal sleeve after thin oil

coating applied thereto.

(4) After applying oil coating to the seal sleeve, insert the rotating portion of the mechanical seal on the seal

sleeve in alignment of the spring rear projection with the notched hole of the seal sleeve. And push the

sliding surface of the washer in the spring compression direction two or three times to check the O-ring

followability.

(5) Insert the spacer sleeve ( 5241. 2 ) in the shaft.

(6) Wipe off the sealing end face of the seat and the washer in finger for complete removal of dust. After that,

joint the seal cover with gasket ( 4000 ) to the casing by tightening hexagon socket head bolts ( 9140 ) with

uniform tightening torque.

This completes the mechanical seal reassembling.

5. Trouble Shooting

When repair is required to eliminate fault or defect, the portion to be repaired must be checked using a proper

instrument. Accordingly, inspect and calibrate the instrument before the use.

5. 1. Discharge capacity down

Possible Cause

Remedy / Corrective Action

1. Too high back pressure.

The actual required head is to high as compared with the initial

design head. Accordingly, consider of the increase in no. of

revolutions, the use of larger impeller, or the increase in no. of

stages.

2. Insufficient exhaust from pump or piping.

Exhaust carefully once more. Repair the piping when deemed as

necessary and add an exhaust valve and an exhaust pipe.

3. Blocked suction pipe or blocked impeller.

Clean the pipe and take out the impeller for inspection and cleaning

when deemed as necessary.

4. Too low suction head.

Check the water level in feed water tank. Also, be sure to check that

Loading...

Loading...