themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmay

resultinnon-conformancewithsafetystandards.

WARNING

Contactwithasharpbladecancauseseriousinjury.

Wearglovesorwrapsharpedgesofthebladewith

arag.

1.Holdthebladeendusingaragorthickly-padded

glove.

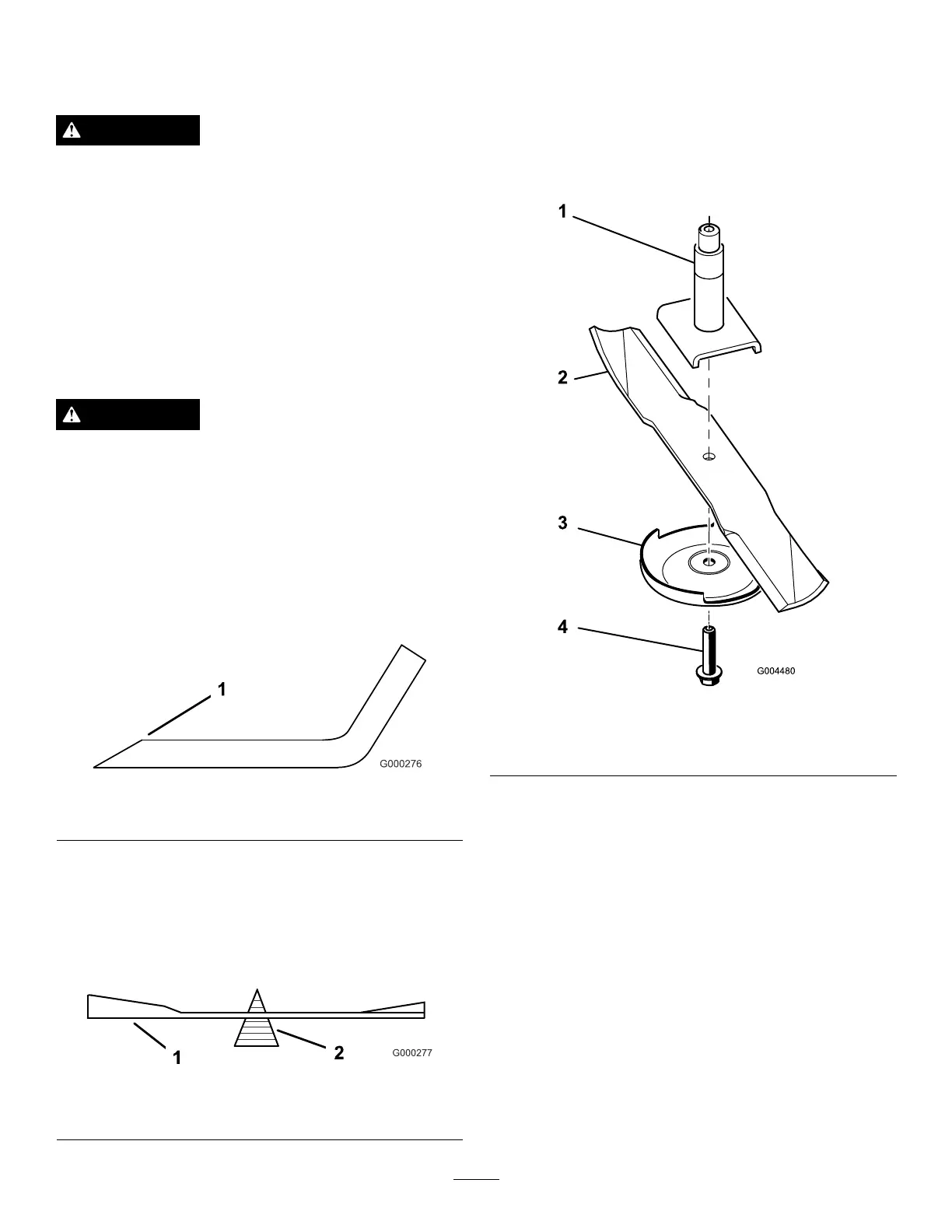

2.Removethebladebolt,anti-scalpplate,andblade

fromthespindleshaft(

Figure23).

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

1.Sharpenthecuttingedgeatbothendsoftheblade

(Figure21).Maintaintheoriginalangle.Theblade

retainsitsbalanceifthesameamountofmaterialis

removedfrombothcuttingedges.

Figure21

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure22).Ifthebladestaysina

horizontalposition,thebladeisbalancedandcanbe

used.Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(

Figure23).Repeatthis

procedureuntilthebladeisbalanced.

Figure22

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure23).

Important:Thecurvedpartoftheblademust

bepointingupwardtowardtheinsideofthe

mowertoensurepropercutting.

2.Installtheanti-scalpplateandbladebolt(

Figure23).

Figure23

1.Spindle

3.Anti-scalpplate

2.SailAreaofBlade

4.BladeBolt

3.Torquethebladeboltto85-110ft-lb(115-150N⋅m).

CorrectingMowerMismatch

Ifthecutisunevenacrossthemowerswath,correct

itasfollows:

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthecuttingunittothedesiredheightofcut,

movethethrottlelevertotheSlowposition,stop

theengine,settheparkingbrake,andremovethe

ignitionkey.

3.Checkandadjustfrontandreartractortirepressure;

refertoCheckingTirePressure.

4.Checkforbentblades.

20

Loading...

Loading...