33

Servicing Belts

Check tension of all belts initially after the first day of

operation and every 100 hours thereafter.

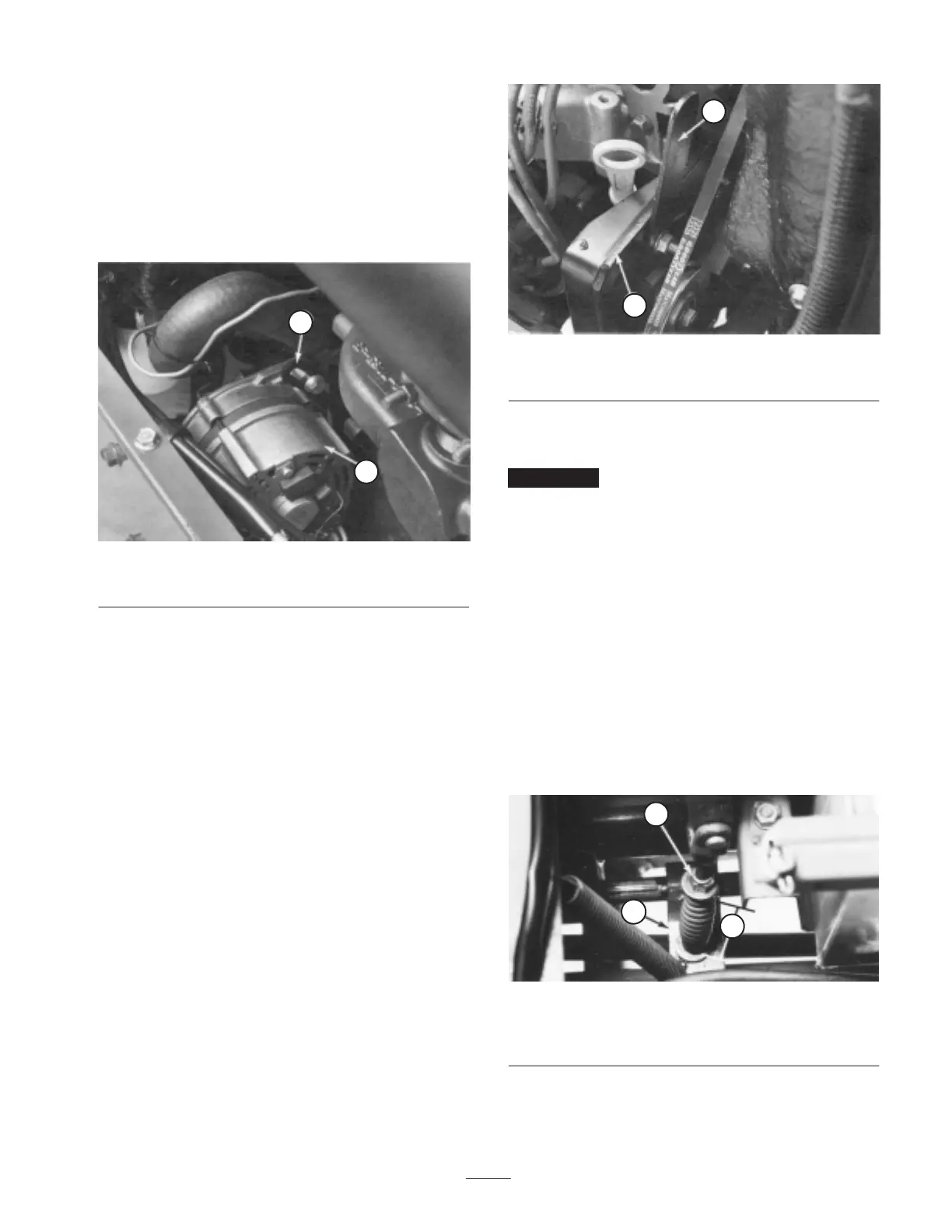

Alternator Belt

A new alternator belt (Fig. 30) is to be tensioned to 65 lbs.

A used belt is to be tensioned to 40 lbs.

1

2

Figure 30

1. Alternator 2. Brace

1. To adjust belt tension, loosen bolt securing brace to

engine, bolt securing alternator to brace and alternator

mounting bolt (Fig. 30).

2. Insert pry bar between alternator and engine and pry out

on alternator (Fig. 30).

3. Hold alternator in position after proper belt tension

setting is achieved and tighten alternator and brace bolts

to secure adjustment.

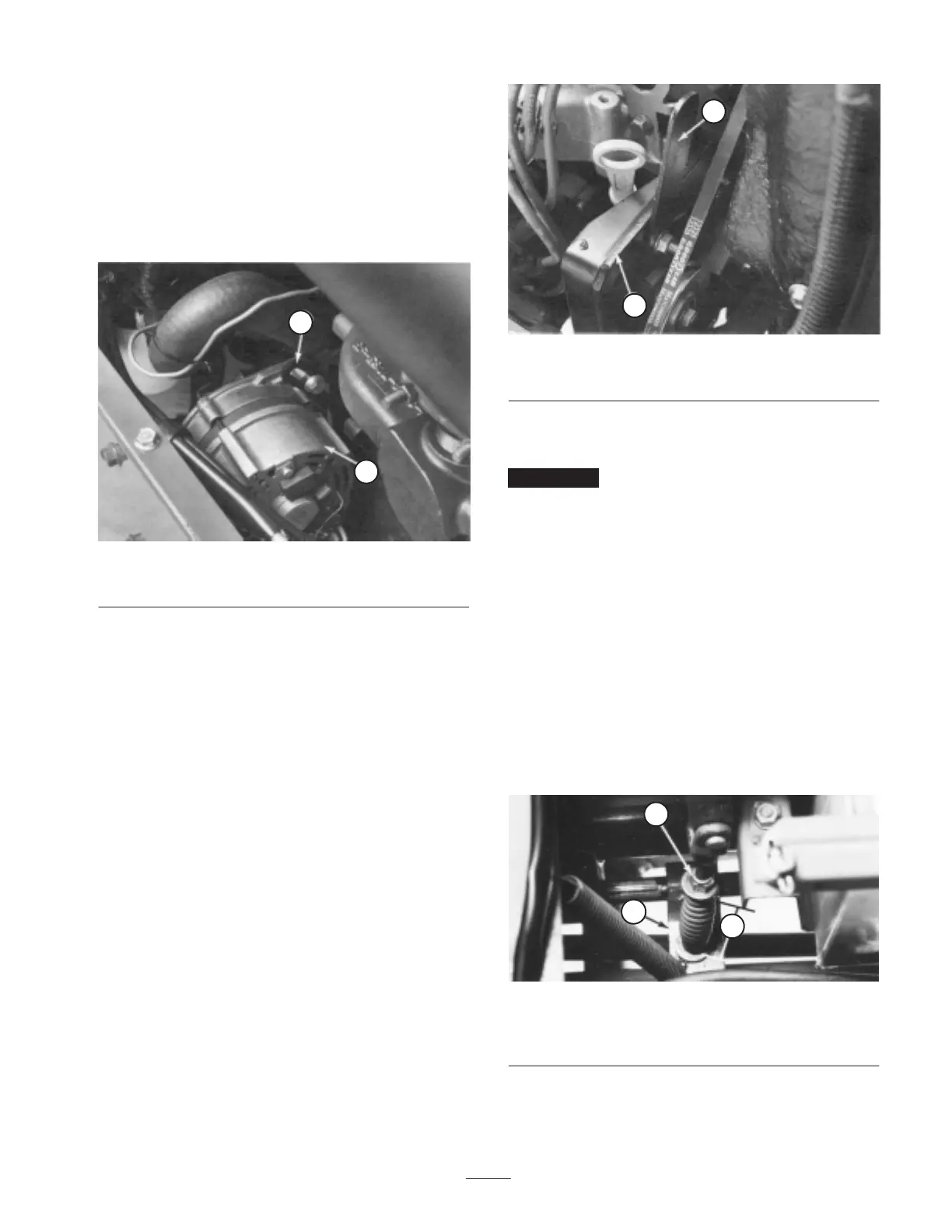

Cooling Fan Belt

A new cooling fan belt (Fig. 31) is to be tensioned to 65

lbs. A used belt is to be tensioned to 40 lbs.

1. To adjust belt tension, loosen upper and lower nuts

securing idler arm to front engine mount (Fig. 31).

2. Pull out on idler arm until desired belt tension is

achieved.

3. Tighten mounting nuts to secure adjustment.

1

2

Figure 31

1. Idler arm 2. Engine mount

Adjusting PTO Drive Belt Tension

Important Check PTO belt tension initially after first

10 hours and 50 hours of operation and after every 100

hours of operation thereafter.

If belt begins to slip because it has stretched or because of

worn linkage adjust as follows:

1. Unlatch and remove instrument cover.

2. Move PTO control lever to ON position.

3. Measure length of PTO spring between flat–washers

(Fig. 32). There should be a spring length of 3-3/16 in.

(81 mm).

4. To adjust, hold head of adjusting screw with wrench

(under PTO actuating arm) and turn locknut (Fig. 32).

5. Move PTO lever to OFF position and install instrument

cover.

1

2

3

Figure 32

1. 3-3/16 in. (81 mm)

2. PTO actuating arm

3. Locknut

Loading...

Loading...