35

1

2

3

5

4

7

6

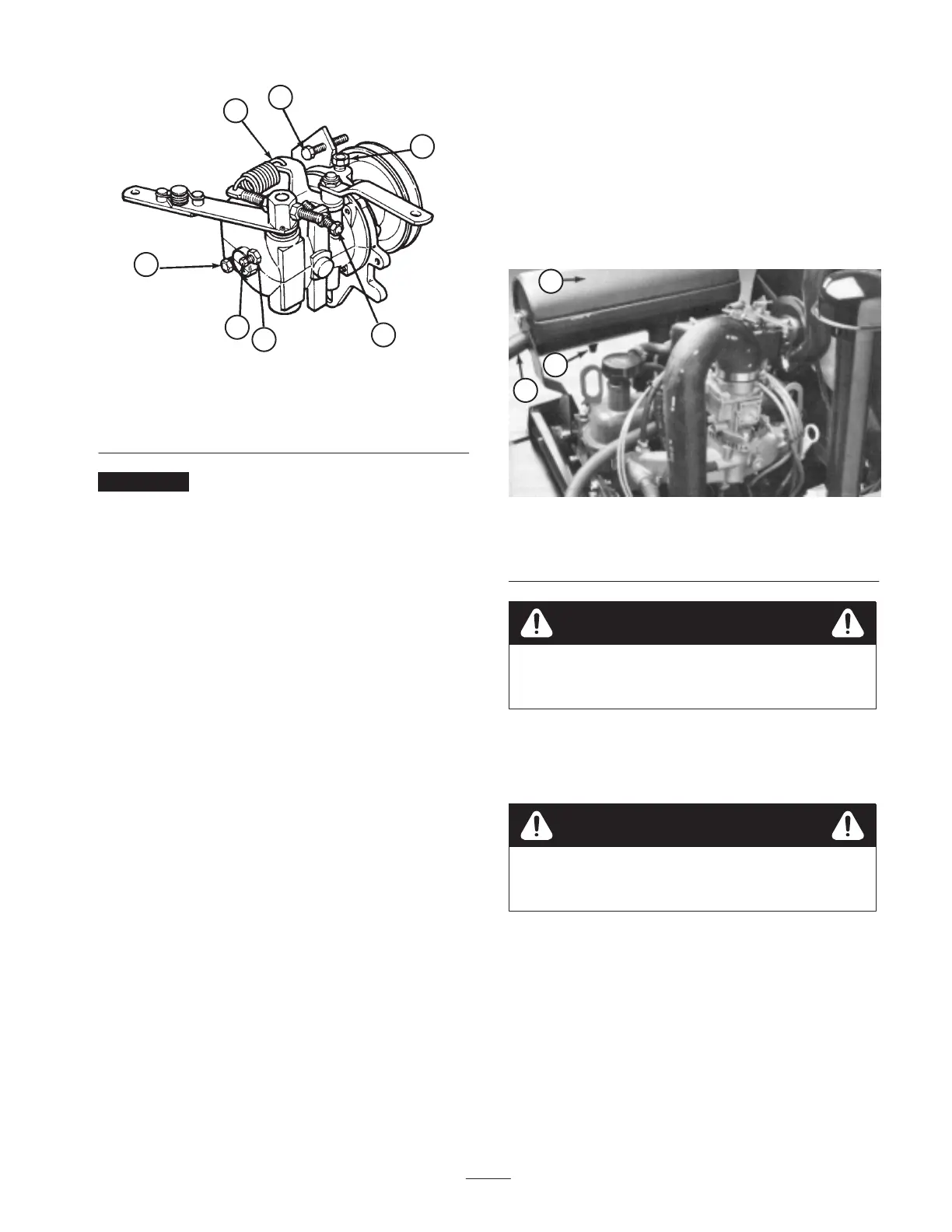

Figure 34

1. High idle stop screw

2. Speed control lever

3. Jam nut

4. Anti–surge screw

5. Oil check plug

6. low idle stop screw

Important Never rotate anti–surge screw in too far so

that speed of engine increases.

9. Bump the throttle lever with your hand so engine speeds

up momentarily. If governor is working properly,

engine speed should return to normal within one or two

surges of the governor. More than two surges of the

governor usually indicates than the anti–surge screw

must be turned in slightly more than it is. When

adjustment is correct, lock jam nut against governor

body.

10. Check low and high idle speed to be sure there is no

change from the initial setting. If high idle sped has

increased, anti–surge has been turned into the governor

too far and it must be backed out. Then repeat the entire

adjustment procedure.

Note: If the throttle control on the instrument panel will not

stay in the FAST position during operation, remove the

panel cover and tighten the nut and capscrew at base of

throttle lever assembly.

Checking Oil Level In Governor

The governor is shipped with oil in it, but the level of oil

must be checked after every 250 hours of operation.

1. Position machine on level surface and shut engine off.

2. Disengage hood latch and open the hood.

3. Clean area around check plug on governor (Fig. 34)

4. Remove check plug. Oil level must be up to bottom of

filler hole. If oil level is low, remove oil fill plug and

add same oil that is being used in engine. When oil is at

point of overflowing out of check plug hole, install the

check plug and fill plug.

Servicing Spark Arrestor

Muffler

Every 200 hours operation, clear the muffler of carbon

buildup.

1. Unlatch and raise hood assembly.

2. Remove pipe plug from clean–out port at lower side of

muffler (Fig. 35).

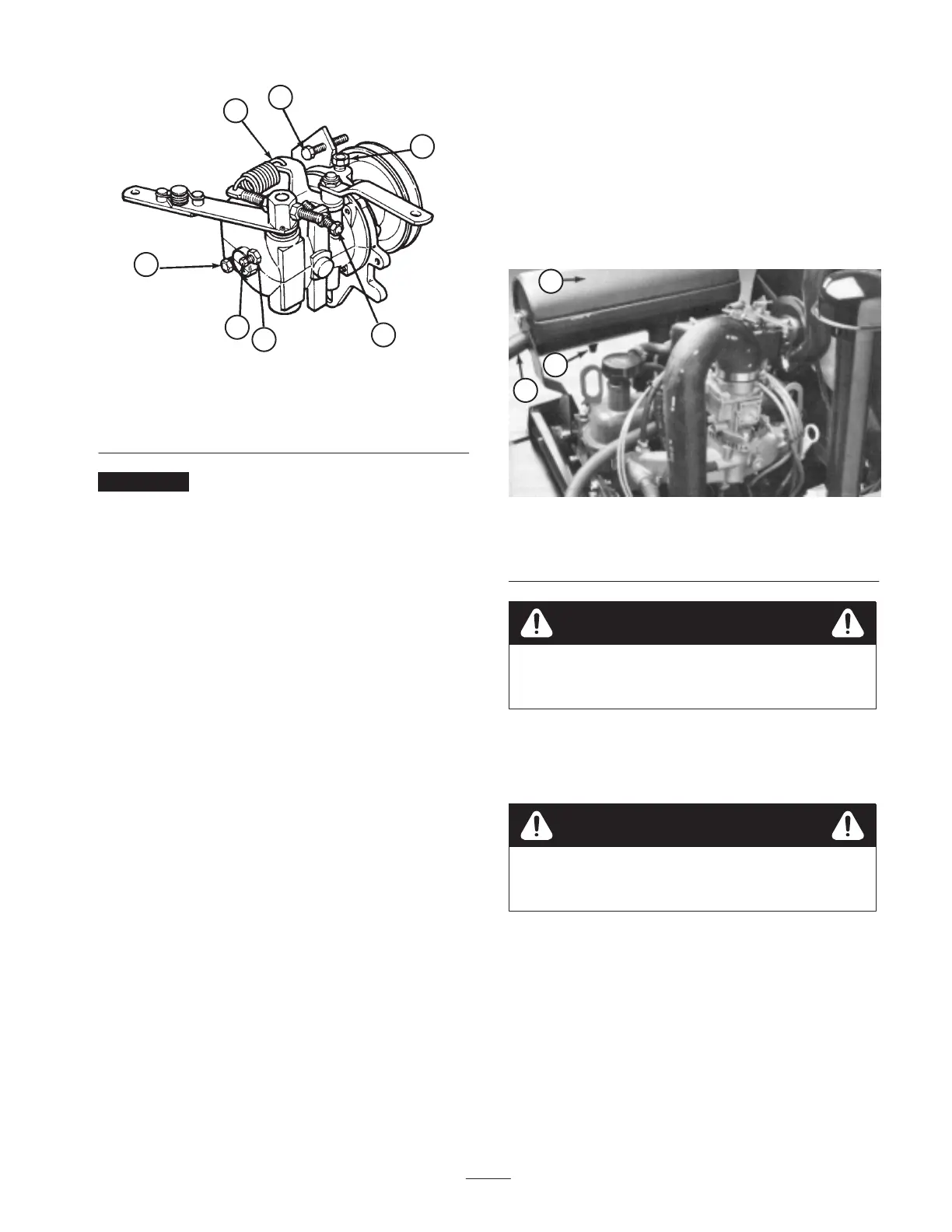

1

2

3

Figure 35

1. Muffler

2. Pipe plug

3. Outlet port

Be careful while working around muffler as it may

be hot and could cause injury.

Caution

3. Start engine. Plug the normal muffler exit with block of

wood or metal plate so exhaust flow will be forced out

of the clean–out port (Fig. 53). Continue to block exit

until carbon deposits cease coming out port.

Do not stand in line with the clean–out port.

Always wear safety glasses.

Caution

4. Stop engine, replace pipe plug, and lower and latch

hood.

Loading...

Loading...