Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

5.CoatbothbatteryconnectionswithGrafo112X

(skin-over)grease,ToroPartNo.505-47,petroleum

jelly,orlightgreasetopreventcorrosion.Slidethe

rubberbootoverthepositiveterminal.

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

6.Installthebatterycover.

Batteryterminalsormetaltoolscouldshort

againstmetalcomponentscausingsparks.

Sparkscancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

BatteryCare

ServiceInterval:Every50hours

Important:Beforeweldingonthemachine,

disconnectthecablefromthenegativebatterypost

topreventdamagetotheelectricalsystem.

Note:Checkthebatteryconditionweeklyorafter

every50hoursofoperation.Keeptheterminalsand

theentirebatterycasecleanbecauseadirtybatterywill

dischargeslowly.Tocleanthebattery,removeitfrom

themachine,washtheentirecasewithasolutionof

bakingsodaandwater.Rinsewithclearwater.Coatthe

batterypostsandcableconnectorswithGrafo112X

(skin-over)grease(ToroPartNo.505-47)orpetroleum

jellytopreventcorrosion.

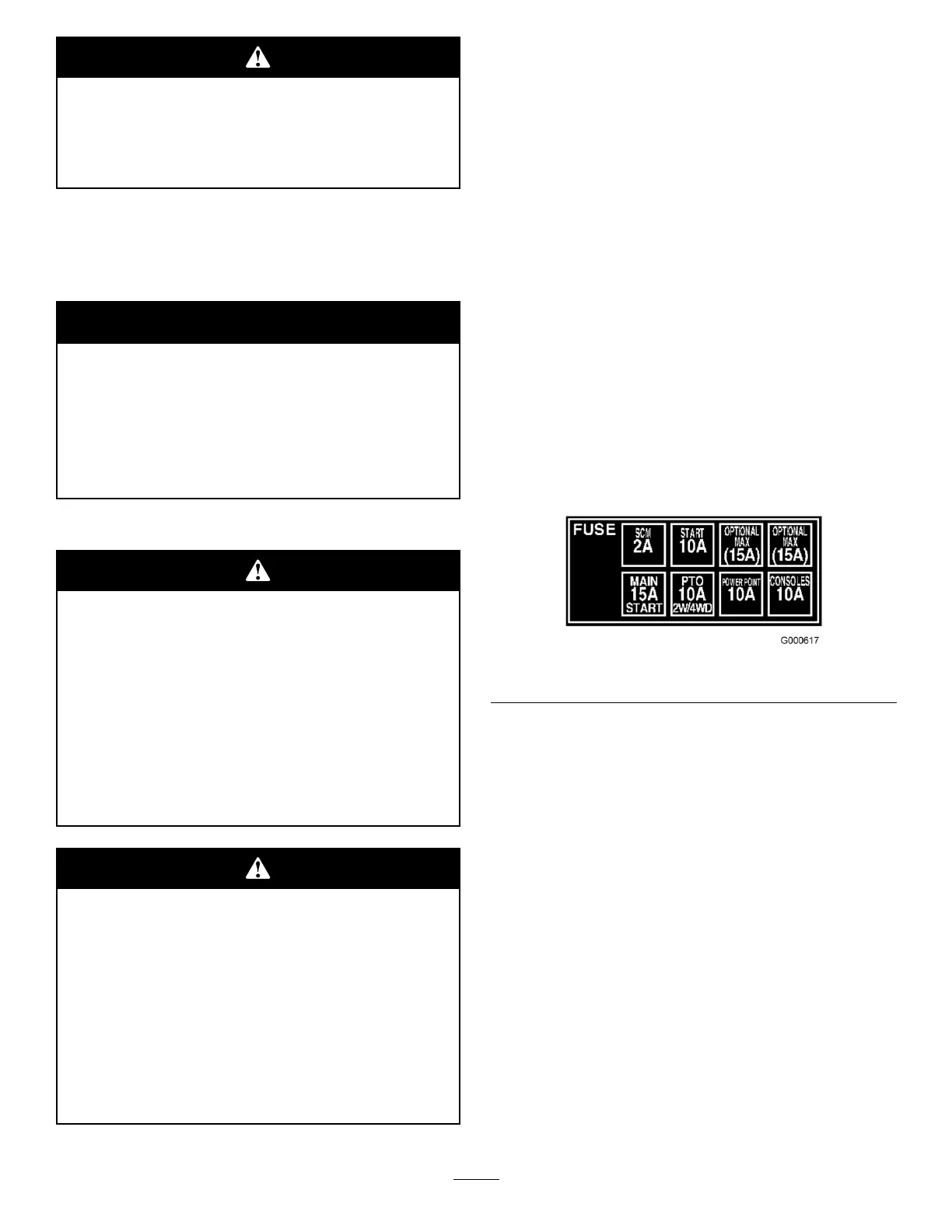

Fuses

Thereare6fusesintheelectricalsystem.Theyare

locatedundertheoperatorscontrolpanel.Rotatelatches

andremovecontrolpanelcover.

Figure43

38

Loading...

Loading...