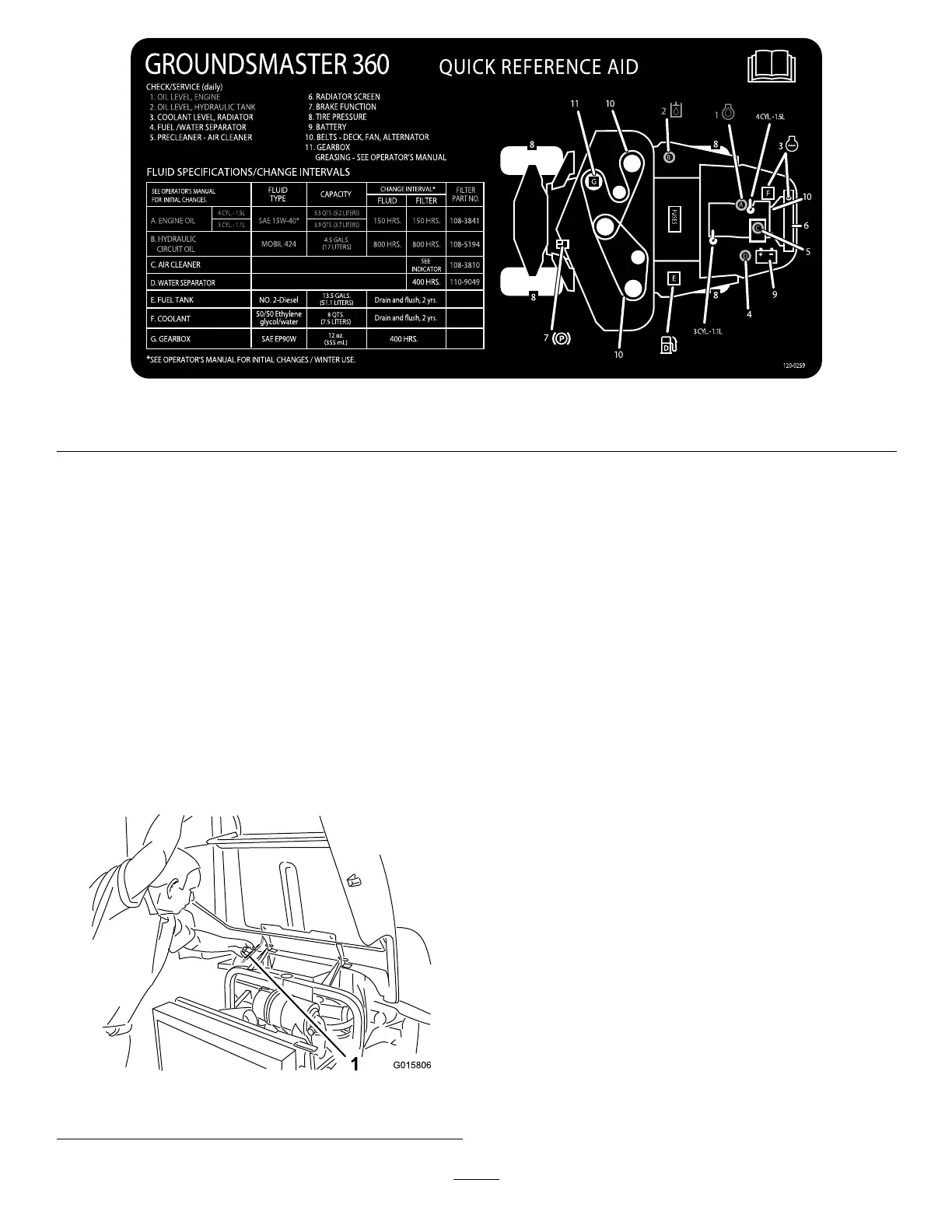

Figure22

ServiceIntervalChart

Premaintenance

Procedures

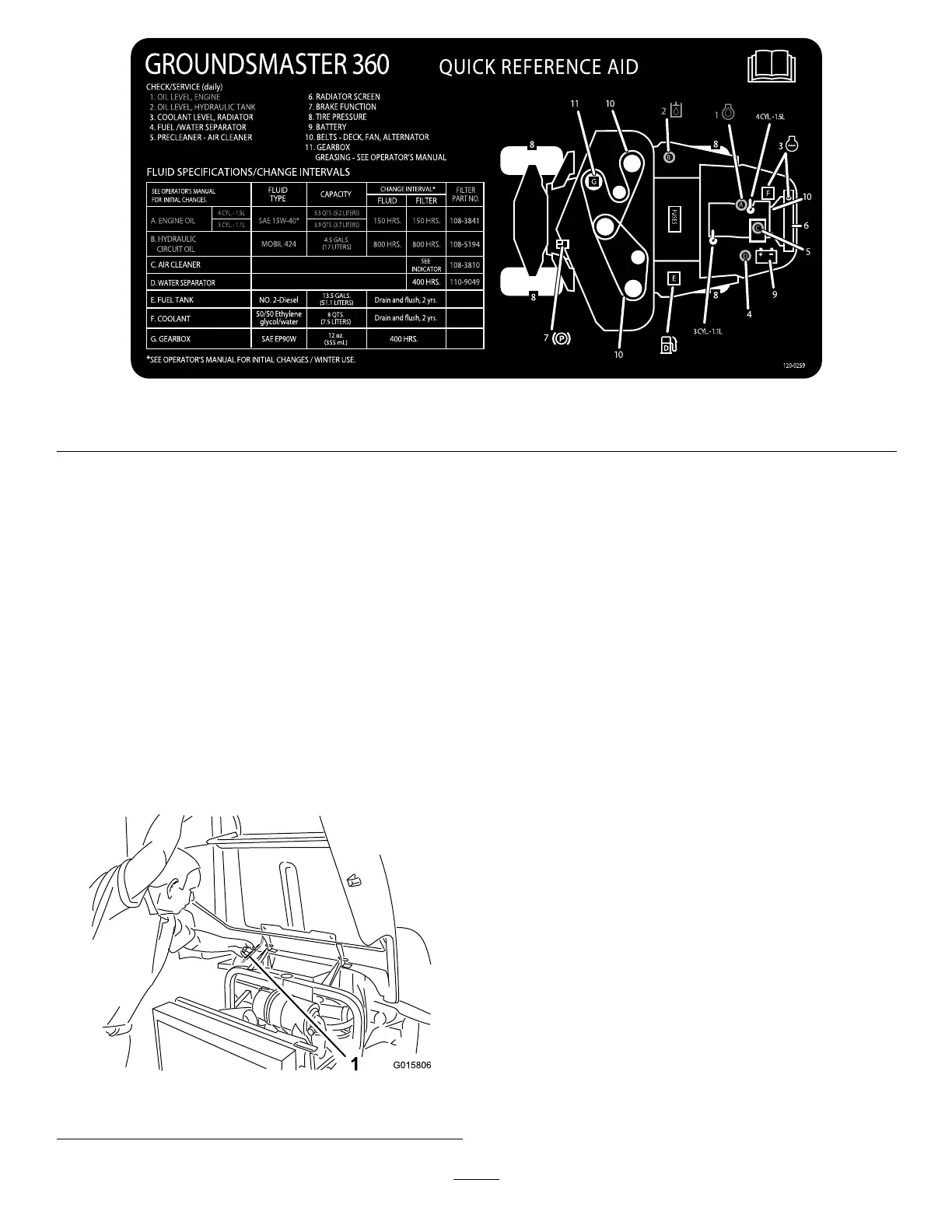

UsingtheHoodPropRod

1.Releasethehoodlatches.

2.Liftuponthehooduntiltheproprodcanbe

positionedbehindtheframetube(Figure23).

3.Lowerthehooduntiltherodisinfrontofandresting

againsttheframetube.

4.Tolowerthehood,raisethehooduntiltheproprod

canberaisedabovetheframetube,thenlowerthe

hood.

5.Securethehoodlatches

Figure23

1.Proprod

Lubrication

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperation.

Bearingsandbushingsmustbelubricateddailywhen

operatingconditionsareextremelydustyanddirty.Dusty

anddirtyoperatingconditionscouldcausedirttogetinto

thebearingsandbushings,resultinginacceleratedwear.

Lubricatethegreasettingsimmediatelyaftereverywashing,

regardlessofintervalspecied.

1.Wipethegreasettingscleansoforeignmattercannot

beforcedintothebearingorbushing.

2.Pumpgreaseintothettings.

3.Wipeoffexcessgrease.

Note:Toaccesstherearsteeringlinkagegreasettings,the

storagecompartmentneedstoberemoved.

28

Loading...

Loading...