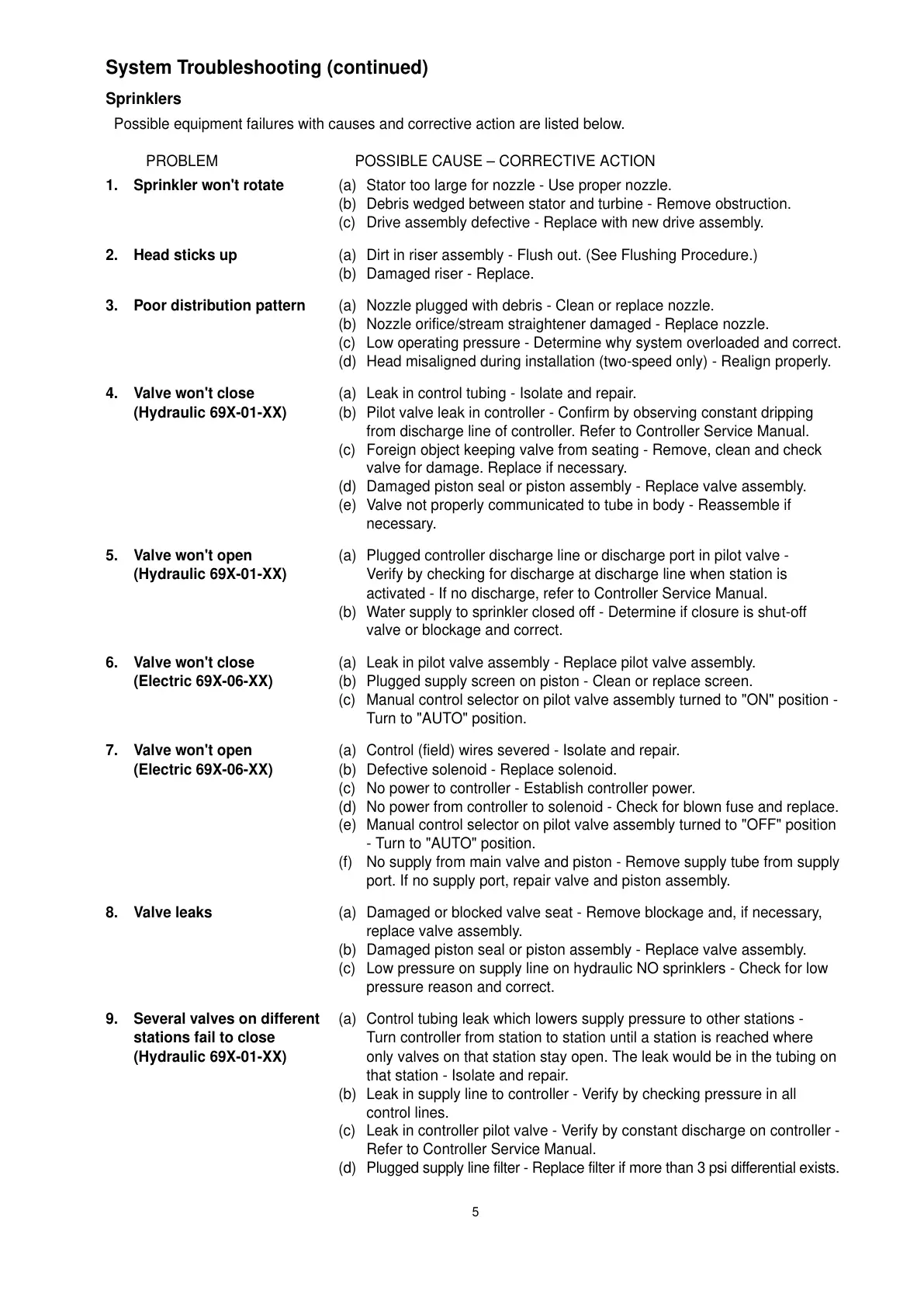

5

System Troubleshooting (continued)

Sprinklers

Possible equipment failures with causes and corrective action are listed below.

PROBLEM POSSIBLE CAUSE – CORRECTIVE ACTION

1. Sprinkler won't rotate (a) Stator too large for nozzle - Use proper nozzle.

(b) Debris wedged between stator and turbine - Remove obstruction.

(c) Drive assembly defective - Replace with new drive assembly.

2. Head sticks up (a) Dirt in riser assembly - Flush out. (See Flushing Procedure.)

(b) Damaged riser - Replace.

3. Poor distribution pattern (a) Nozzle plugged with debris - Clean or replace nozzle.

(b) Nozzle orifice/stream straightener damaged - Replace nozzle.

(c) Low operating pressure - Determine why system overloaded and correct.

(d) Head misaligned during installation (two-speed only) - Realign properly.

4. Valve won't close (a) Leak in control tubing - Isolate and repair.

(Hydraulic 69X-01-XX) (b) Pilot valve leak in controller - Confirm by observing constant dripping

from discharge line of controller. Refer to Controller Service Manual.

(c) Foreign object keeping valve from seating - Remove, clean and check

valve for damage. Replace if necessary.

(d) Damaged piston seal or piston assembly - Replace valve assembly.

(e) Valve not properly communicated to tube in body - Reassemble if

necessary.

5. Valve won't open (a) Plugged controller discharge line or discharge port in pilot valve -

(Hydraulic 69X-01-XX) Verify by checking for discharge at discharge line when station is

activated - If no discharge, refer to Controller Service Manual.

(b) Water supply to sprinkler closed off - Determine if closure is shut-off

valve or blockage and correct.

6. Valve won't close (a) Leak in pilot valve assembly - Replace pilot valve assembly.

(Electric 69X-06-XX) (b) Plugged supply screen on piston - Clean or replace screen.

(c) Manual control selector on pilot valve assembly turned to "ON" position -

Turn to "AUTO" position.

7. Valve won't open (a) Control (field) wires severed - Isolate and repair.

(Electric 69X-06-XX) (b) Defective solenoid - Replace solenoid.

(c) No power to controller - Establish controller power.

(d) No power from controller to solenoid - Check for blown fuse and replace.

(e) Manual control selector on pilot valve assembly turned to "OFF" position

- Turn to "AUTO" position.

(f) No supply from main valve and piston - Remove supply tube from supply

port. If no supply port, repair valve and piston assembly.

8. Valve leaks (a) Damaged or blocked valve seat - Remove blockage and, if necessary,

replace valve assembly.

(b) Damaged piston seal or piston assembly - Replace valve assembly.

(c) Low pressure on supply line on hydraulic NO sprinklers - Check for low

pressure reason and correct.

9. Several valves on different (a) Control tubing leak which lowers supply pressure to other stations -

stations fail to close Turn controller from station to station until a station is reached where

(Hydraulic 69X-01-XX) only valves on that station stay open. The leak would be in the tubing on

that station - Isolate and repair.

(b) Leak in supply line to controller - Verify by checking pressure in all

control lines.

(c) Leak in controller pilot valve - Verify by constant discharge on controller -

Refer to Controller Service Manual.

(d) Plugged supply line filter - Replace filter if more than 3 psi differential exists.

Loading...

Loading...