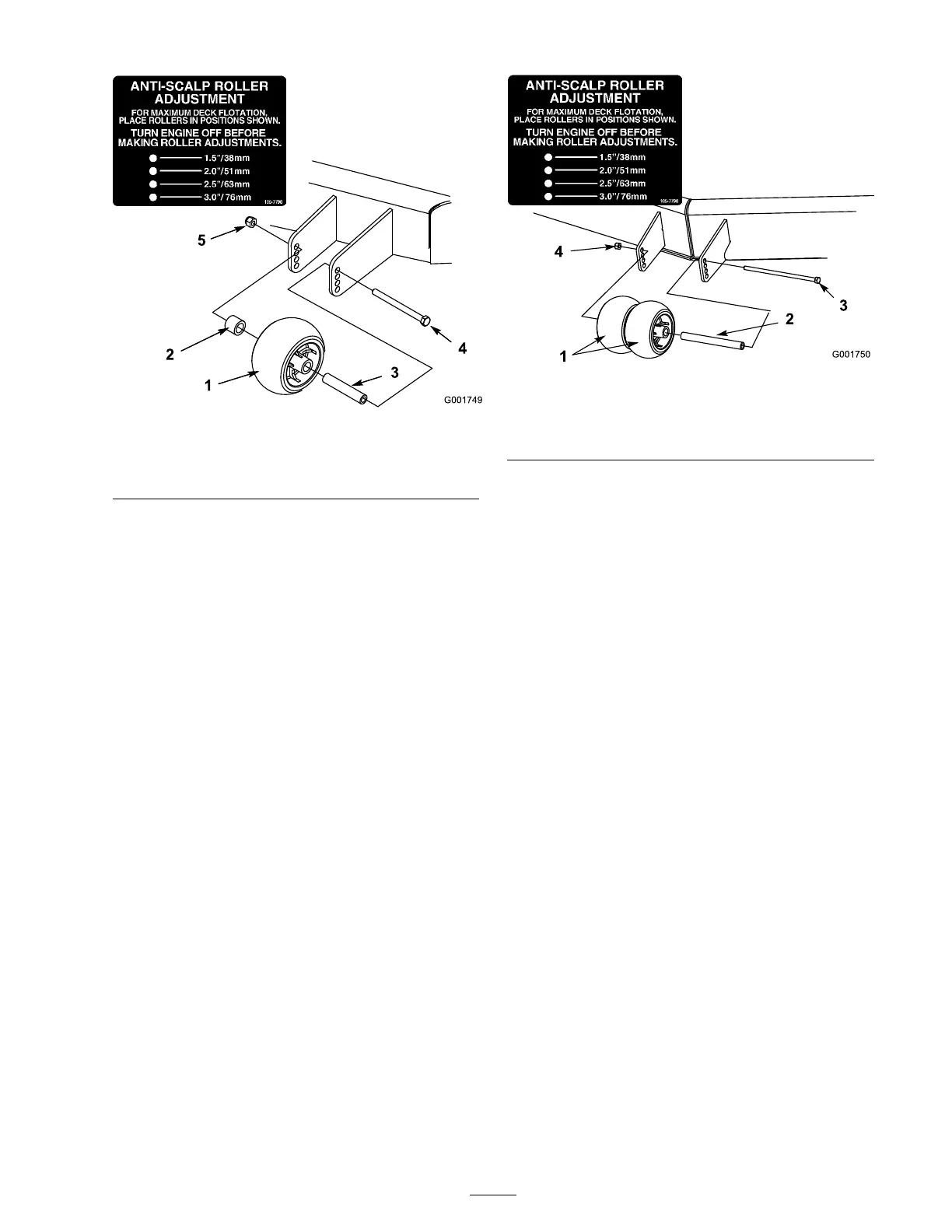

Figure 18

1. Outer roller 4. Bolt

2. Spacer

5. Nut

3. Bushing

4. Select a hole so that the outer roller is

positioned to the nearest cor responding

height-of-cut desired ( Figure 18 ).

5. Install the outer roller , bushing, spacer , bolt,

and n ut ( Figure 18 ).

6. T or que the bolt to 40 to 45 ft-lb (54 to 61

N ⋅ m).

Adjusting the Center Rollers

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position, and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. After adjusting the height-of-cut, remo v e the

flang e n ut, bushing, and bolt ( Figure 19 ).

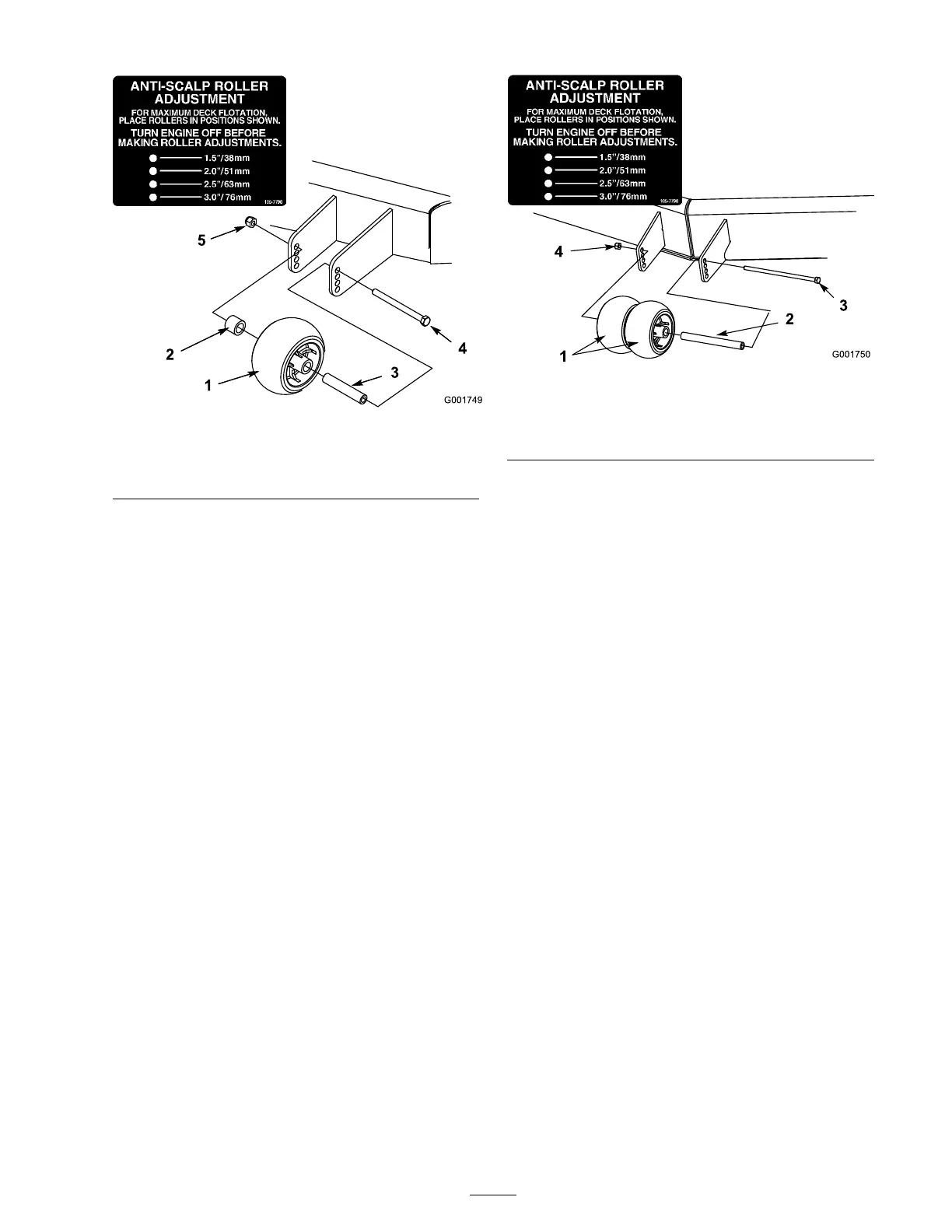

Figure 19

1. Outer roller 4. Bolt

2. Spacer

5. Nut

3. Bushing

4. Select a hole so that the center rollers are

positioned to the nearest cor responding

height-of-cut desired ( Figure 19 ).

Note: Do not adjust the rollers to suppor t

the mo w er housing .

5. Install the center rollers , bushing, spacer , bolt,

and n ut ( Figure 19 ).

6. T or que the bolt to 40 to 45 ft-lb (54 to 61

N ⋅ m).

Adjusting the Flow Bafe

T he mo w er disc harg e flo w can be adjusted for

different types of mo wing conditions . P osition the

cam loc ks and baffle to gi v e the best quality of cut.

1. Diseng ag e the PTO , mo v e the motion control

lev ers to the neutral loc k ed position and set

the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. T o adjust the cam loc ks , swing the lev er up to

loosen the cam loc k ( Figure 20 ).

4. Adjust the baffle and cam loc ks in the slots to

the desired disc harg e flo w .

5. Swing the lev er bac k o v er to tighten the baffle

and cam loc ks ( Figure 20 ).

6. If the cams do not loc k the baffle into place or

it is too tight, loosen the lev er and then rotate

23

Loading...

Loading...