Lubrication

GreasingtheBearings

ServiceInterval:Every25hours—Greaseallthelubrication

points.

GreaseType:No.2GeneralPurpose,Lithium-BaseGrease

1.Parkthemachineonalevelsurface,anddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothepark

position,stoptheengine,removethekey,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettings(Figure25andFigure26)with

arag.

Note:Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

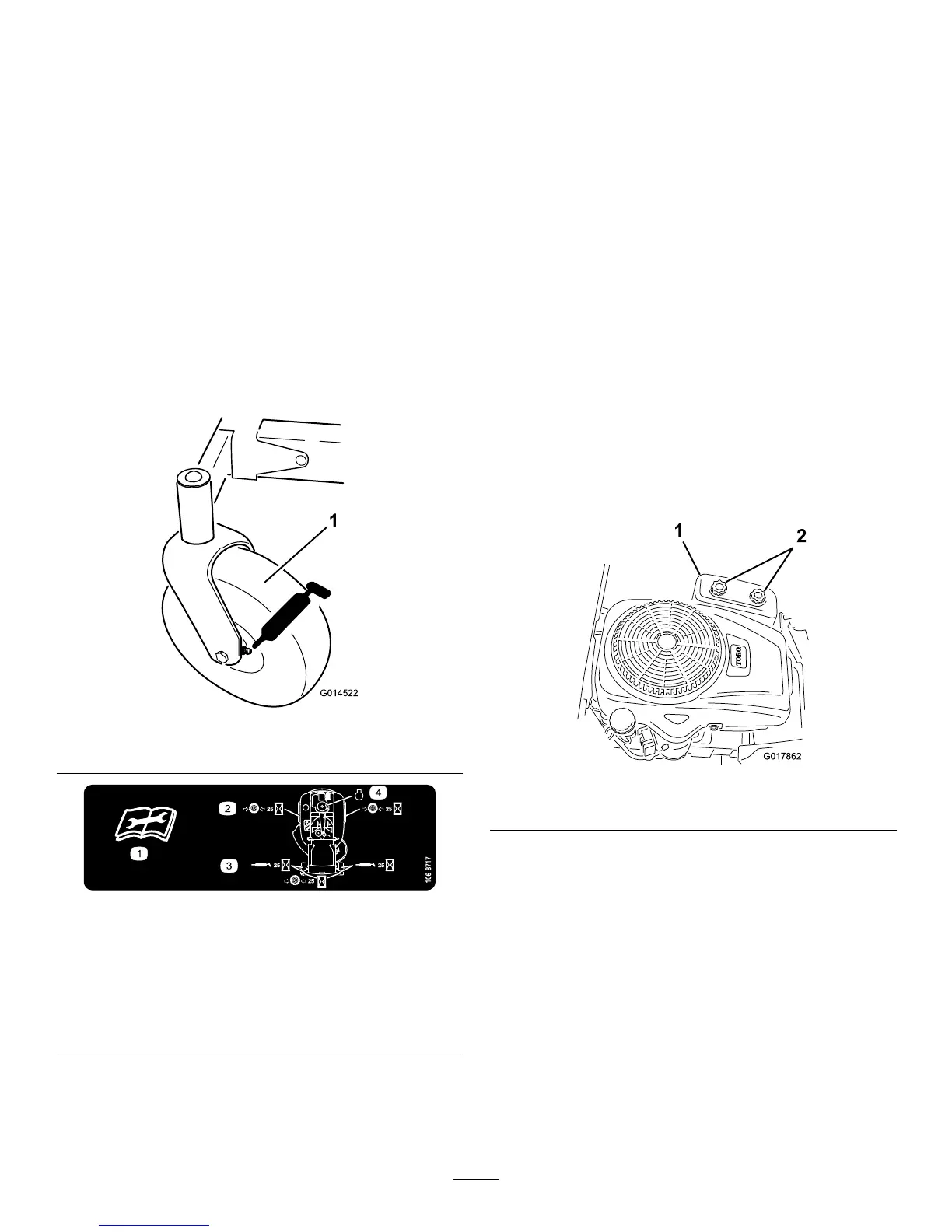

Figure25

1.Frontcastertire

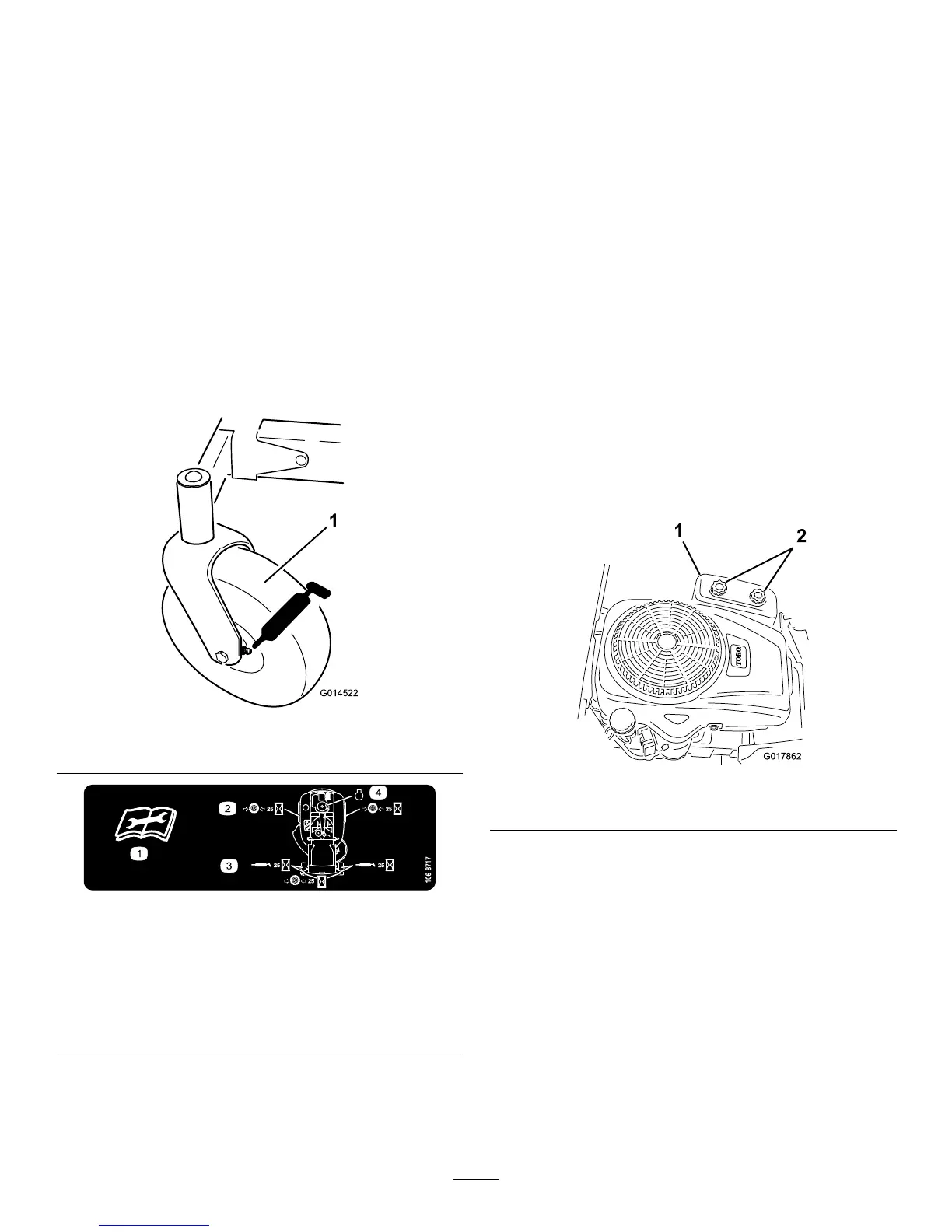

Figure26

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

3.Greaseevery25operating

hours

2.Checkthetirepressure

every25operatinghours

4.Engine

4.Connectagreaseguntoeachtting(Figure25and

Figure26).

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theaircleanerfoamelement.

Every50hours—Replacetheaircleanerpaper

element.

Note:Servicetheaircleanermorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFoamandPaper

Elements

1.Disengagetheblade-controlswitch(PTO).

2.Stoptheengine,waitforallmovingpartstostop,and

removethekeybeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage.

4.Removetheair-cleanercoverbyunscrewingthe2

knobs(

Figure27).

Figure27

1.Air-cleanercover2.Knobs

5.Carefullyremovethefoamandpaperlterelements

fromtheair-cleanerhousing(Figure28).

24

Loading...

Loading...