RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,iftheblade

isoutofbalance,orifthebladeisbent.Forbestperformance

andcontinuedsafetyconformanceofthemachine,use

genuineTororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladestiffener(32-inchdecksonly),blade

bolt,thecurvedwasher,andthebladefromthespindle

shaft(Figure56andFigure57).

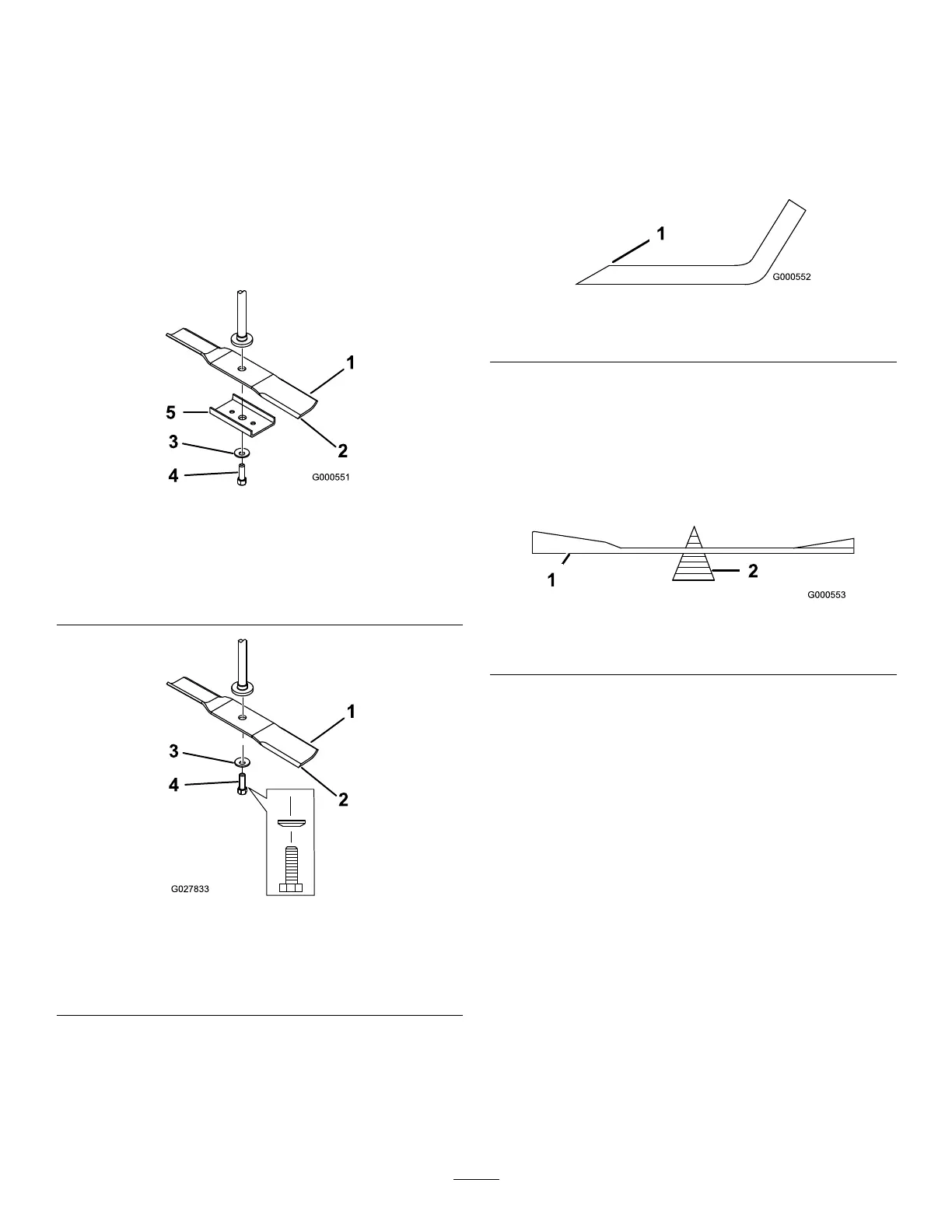

g000551

Figure56

81cm(32-Inch)Decks

1.Sailareaoftheblade

4.Bladebolt

2.Blade

5.Bladestiffener

3.Curvedwasher

g027833

Figure57

107cm(42-Inch)Decks

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

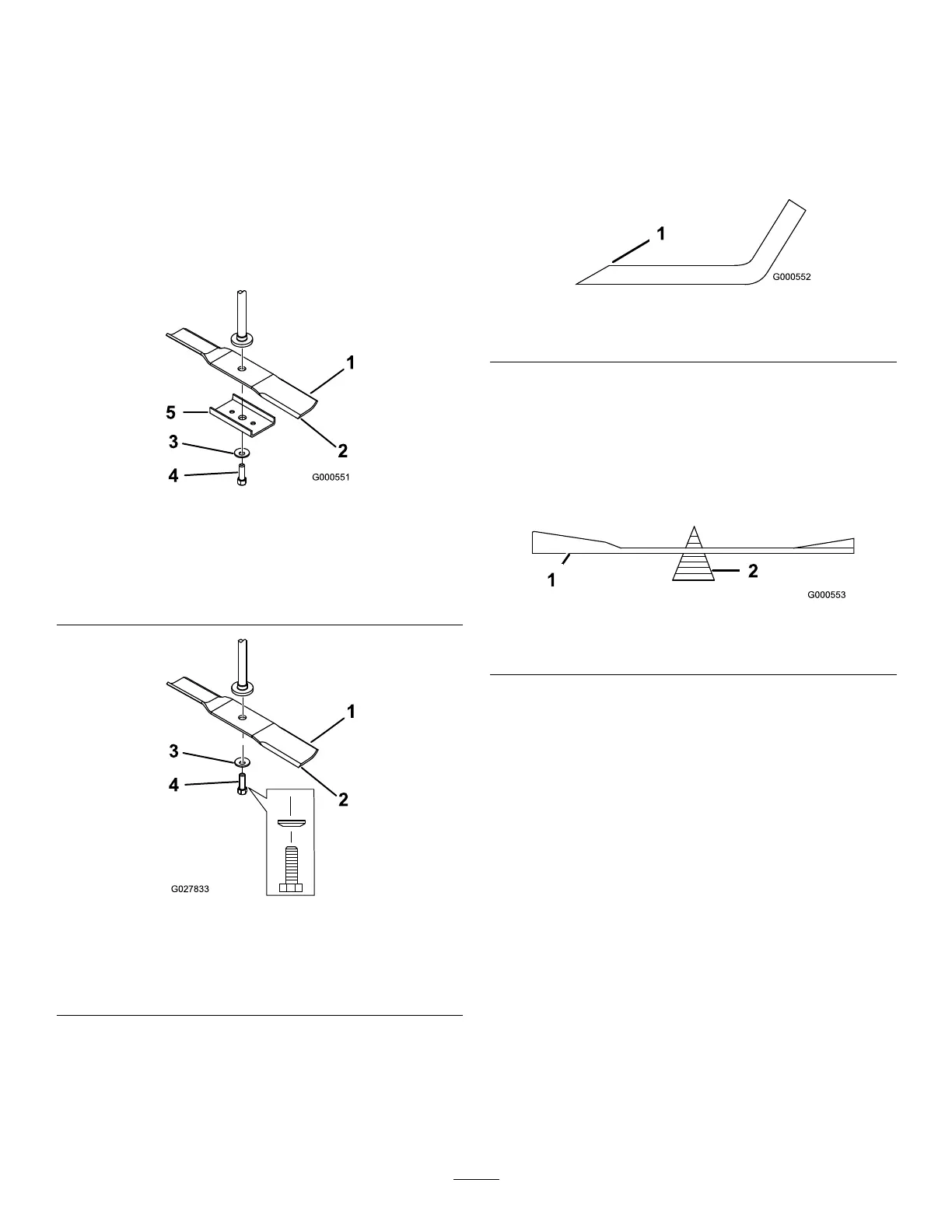

theblade(Figure58).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

g000552

Figure58

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure59).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure58).

g000553

Figure59

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeisbalanced.

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure57).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthebladestiffener(32-inchdecksonly),curved

washer(cuppedsidetowardtheblade),andbladebolt

(Figure57).

3.Torquethebladeboltto47to88N∙m(35to65ft-lb).

40

Loading...

Loading...