Replacetheaircleanerelementyearly,orevery100

hours.

1.Opentheaircleanercoverdoorontheblower

housingtoaccesstheaircleanerelement(Figure34).

2.Unhookthelatchandremovetheair

cleaner(Figure34).

3.Removethefoamelementandinspect.Cleanand

replaceasnecessary.

4.Gentlytapthepaperelementtodislodgedirt.Do

notwashthepaperelementorusepressurized

air,asthiswilldamagetheelement.Replaceadirty,

bent,ordamagedelement.Handlethenewelement

carefully;donotuseifthesealingsurfacesarebent

ordamaged.

5.Cleantheaircleanerbaseasrequiredandcheck

condition.

6.Installthepaperelementontotheaircleanerbase.

Securewiththelatch.

7.Closetheaircleanercoverdoor.

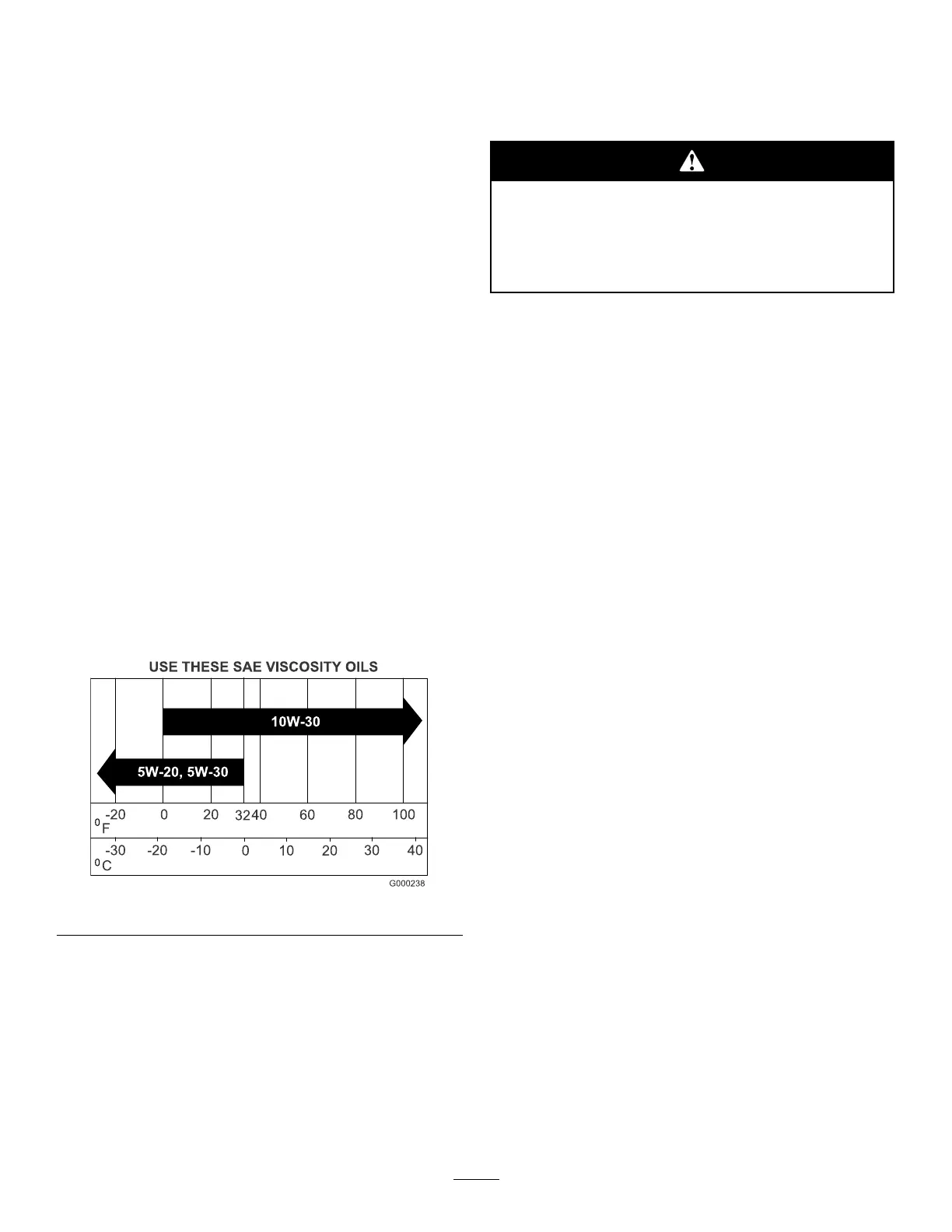

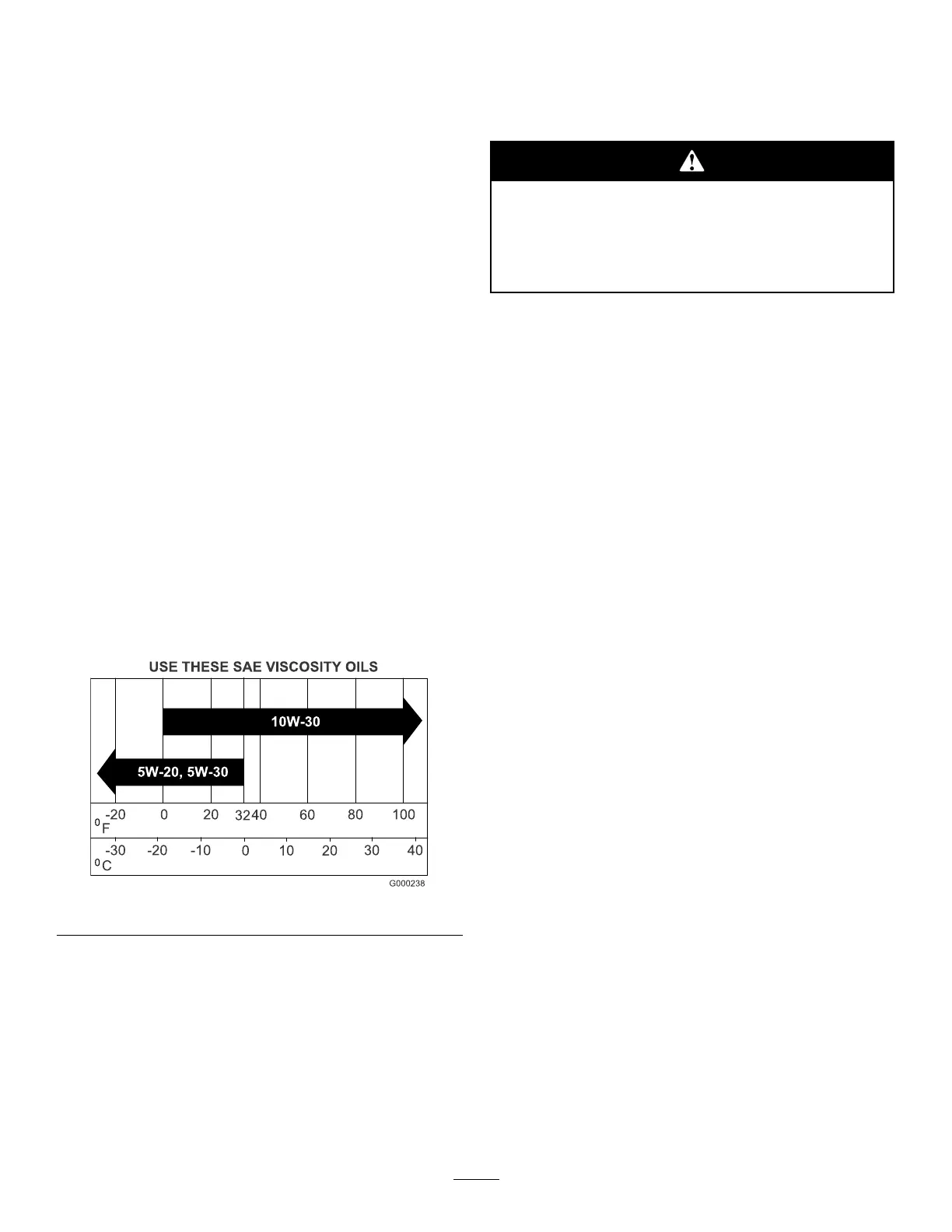

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,or

higher)

CrankcaseCapacity:1.6-1.8qt(1.7-1.9l)whenthe

lterischanged

Viscosity:Seethetablebelow .

Figure35

Important:UseotherthanserviceclassSG,SH,SJ,

orhigheroilorextendingoilchangeintervalslonger

thanrecommendedcancauseenginedamage.

Note:Syntheticoilsmeetingthelistedclassications

maybeusedwithoilchangesperformedatthe

recommendedintervals.Howevertoallowpistonrings

toproperlyseat,aneworrebuiltengineshouldbe

operatedforatleast50hoursusingstandardpetroleum

basedoilbeforeswitchingtosyntheticoil.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Removethedipstickandwipetheoiloff.

Note:Checkthestyleofoildipstickfortheengine.

Dipstickswiththreadedcapsareuseddifferently

whencheckingtheoillevelthandipsticksthatare

seatedbypushingthemintoplace.

5.Reinsertthedipstickintothetubetochecktheoil

level:

•Threadeddipstickcaps:restthecaponthe

tube.Turnitcouterclockwiseuntiltheoildipstick

dropsdowntothelowestpointofthethread

leads.Donotscrewthecapontothetube.

•Unthreadeddipstickcaps:reinsertthedipstick

andpushrmlyintoplace.

6.Removethedipstickoutandchecktheoillevel.

Theoillevelshouldbeupto,butnotover,the

“FULL”or“F”markonthedipstick

7.Ifthelevelislow,addoilofthepropertype,uptothe

“FULL”or“F”markonthedipstick.Alwayscheck

thelevelwiththedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

Neveroperatetheenginewiththeoillevelbelowthe

31

Loading...

Loading...