fromthebelttoreleasethebelttension(Figure

101).

Note:Loosenthenutenoughtoallowtheidler

armtopassthestopbolt.

Note:Ifthestopboltiseverremovedfromthe

mountingtab,makesurethatitisinstalledagain

intheholethatalignsthestop-boltheadwith

theidlerarm.

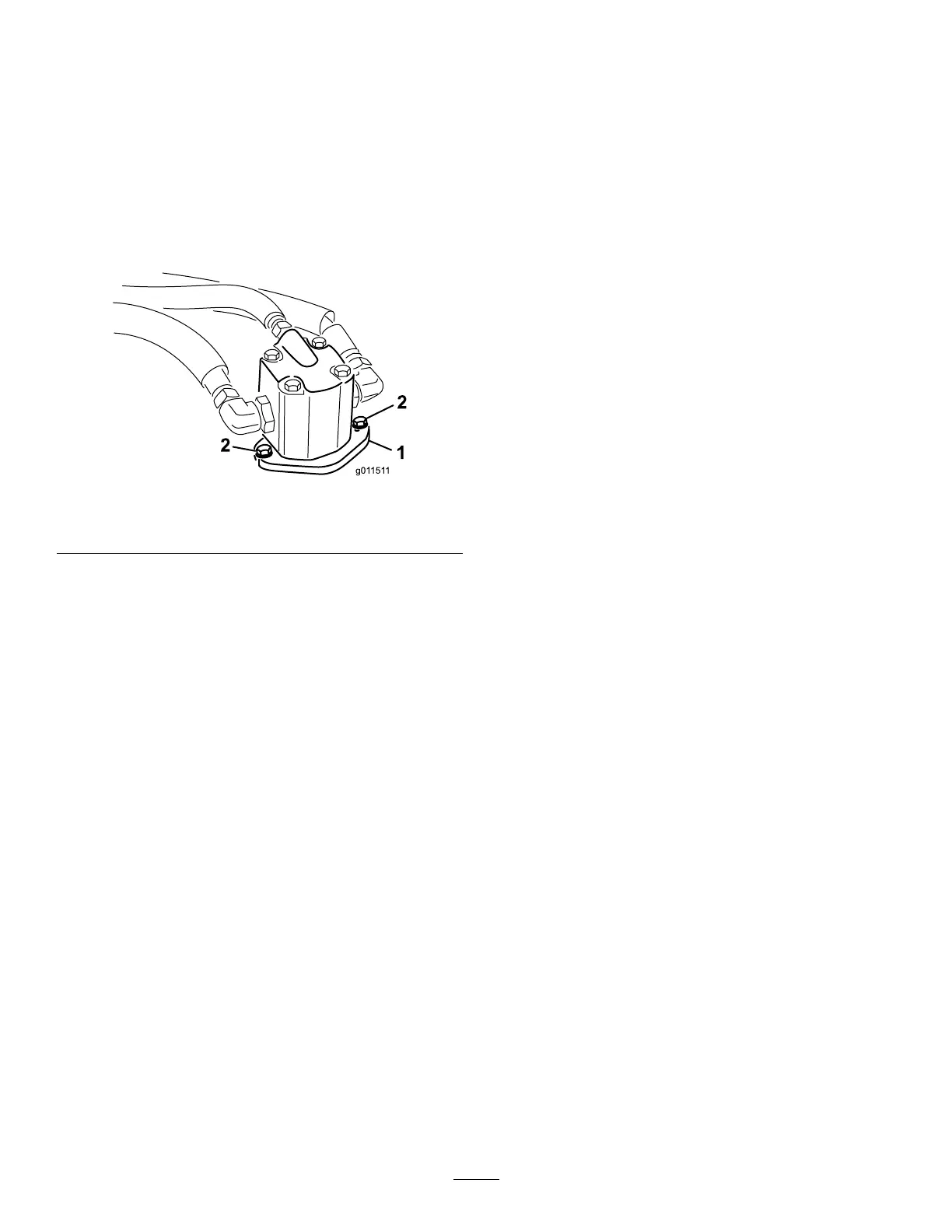

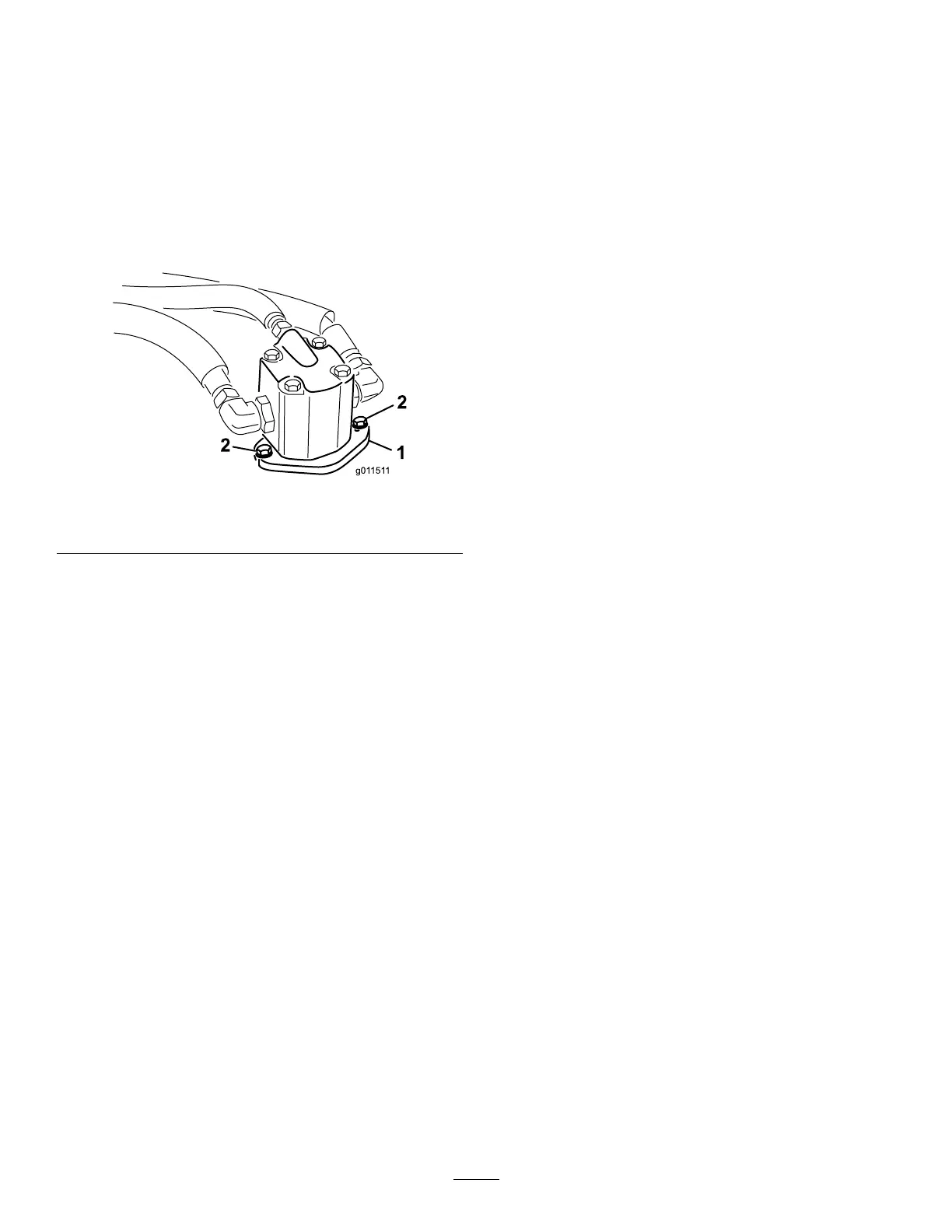

4.Removetheboltssecuringthehydraulicmotor

tothemowerdeck(Figure102).

g011511

Figure102

1.Hydraulicmotor2.Mountingbolts

5.Liftthemotoroffthemowerdeckandlayiton

topofthemowerdeck.

6.Removetheoldbeltfromaroundthespindle

pulleysandidlerpulley.

7.Routethenewbeltaroundthespindlepulleys

andidler-pulleyassembly.

8.Positionthehydraulicmotoronthemowerdeck

afterroutingthebeltaroundthepulleys.Mount

themotortothemowerdeckwiththebolts

previouslyremoved.

Note:Ensurethatthebeltispositionedonthe

springsideofthebeltguide(Figure101).

9.Connecttheextensionspring(Figure101)tothe

eyeboltandtensionthebeltasfollows:

•Whenproperlytensioned,theinside

measurementoftheextensionspring(hook

tohook)shouldbeapproximately8.27to

9.53cm(3.25to3.75inches).

•Whenyouattainthecorrectspringtension,

adjustthestopbolt(carriagebolt)untilthere

isapproximately0.17to0.47cm(0.065to

0.185inches)clearancebetweenthehead

oftheboltandtheidlerarm.

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Ensurethatallhydraulic-uidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.Injecteduidmustbe

surgicallyremovedwithinafewhoursbya

doctor.

ServicingtheHydraulic

System

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Thereservoirislledatthefactorywithapproximately

29L(7.75USgallons)ofhigh-qualityhydraulicuid.

Checkthelevelofthehydraulicuidbeforetheengine

isrststartedanddailythereafter.Therecommended

replacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid

(Availablein19L(5USgallons)pailsor208L(55US

gallons)drums.SeethePartsCatalogoryourT oro

Distributorforpartnumbers).

Alternativeuids:IftheT orouidisnotavailable,

otherconventional,petroleum-baseduidsmaybe

used,providedtheymeetallofthefollowingmaterial

propertiesandindustryspecications.Checkwith

youroilsuppliertoseewhethertheoilmeetsthese

specications.

Note:T orodoesnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswhowill

standbehindtheirrecommendation.

71

Loading...

Loading...