Turntheltersclockwiseuntilrubbersealcontacts

thelteradapterthentightenthelteranadditional

3/4to1fullturn.

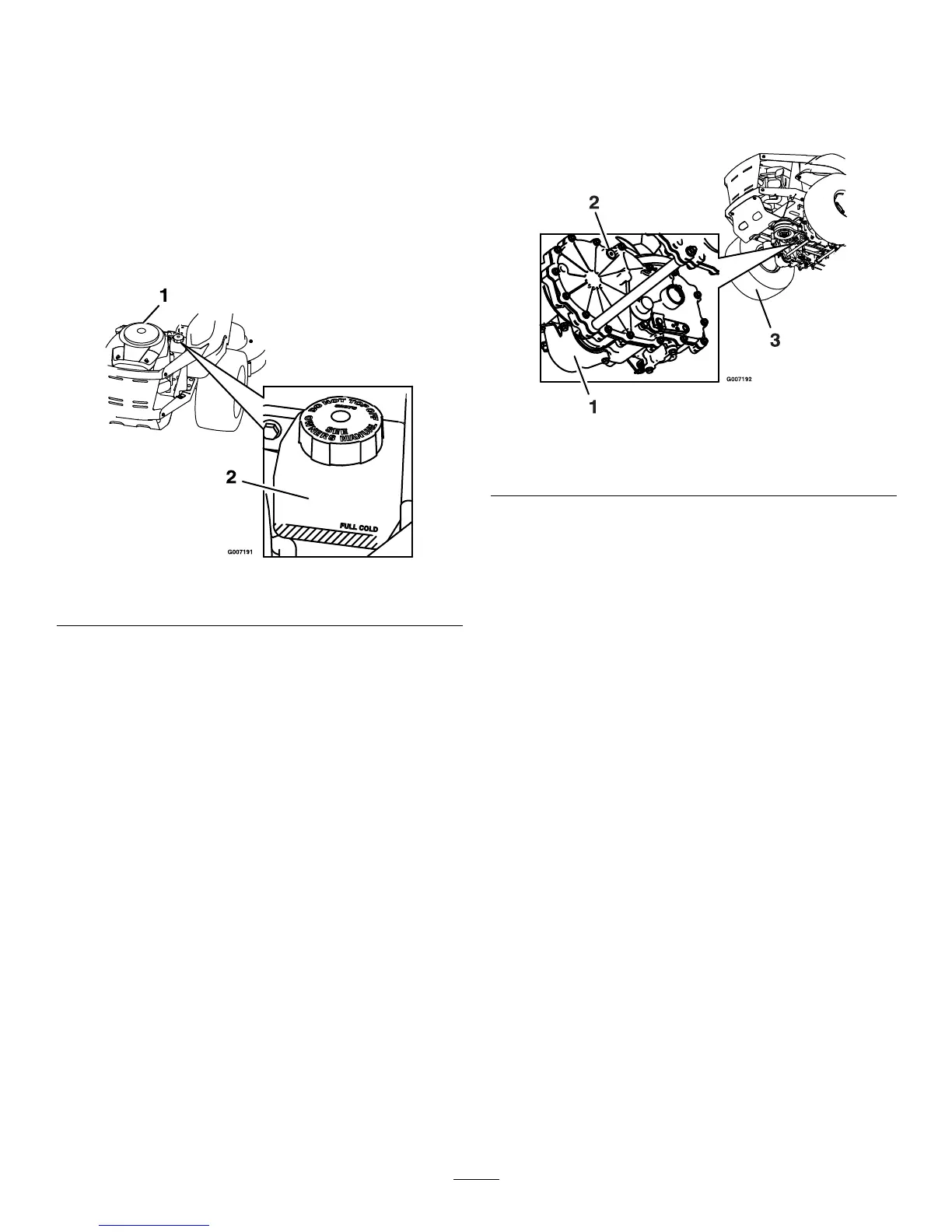

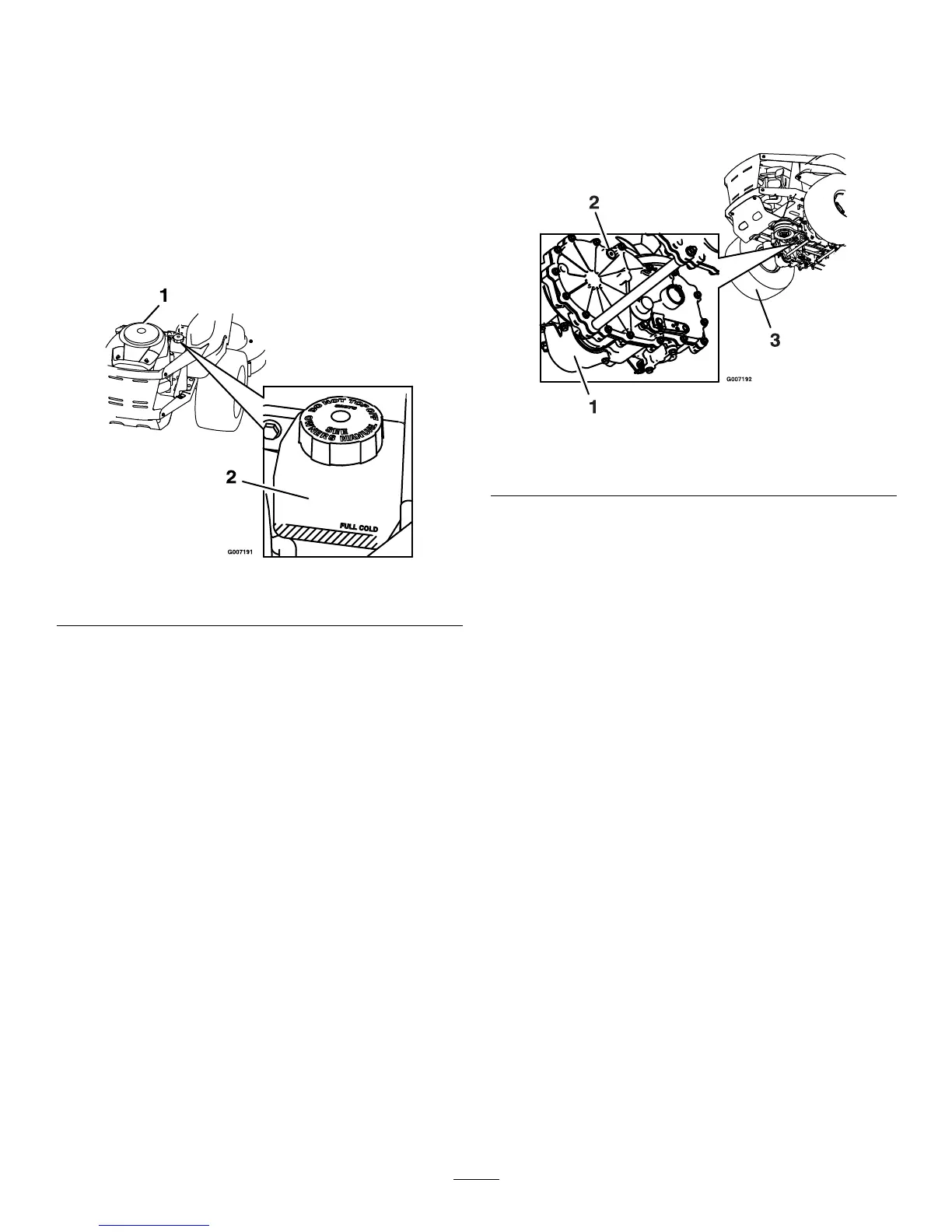

5.Removetheventplugoneachtransmissionandll

throughexpansionreservoir,whenoilcomesoutof

ventreinstallplug.Torqueplugsto180in-lb(244

N-m).ContinuetoaddoiluntilitreachestheFULL

COLDlineontheexpansionreservoir.

Figure37

1.Oillter3.Leftreartire

2.Ventplug

6.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

7.Startengineandmovethrottlecontrolaheadto1/2

throttleposition.Disengageparkingbrake.

A.Withthebypassvalveopenandtheengine

running,slowlymovethedirectionalcontrolin

bothforwardandreverse(5or6times).

B.Withthebypassvalveclosedandtheengine

running,slowlymovethedirectionalcontrol

inbothforwardandreversedirections(5to6

times).Checktheoillevel,andaddoilasrequired

afterstoppingtheengine.

C.Itmaybenecessarytorepeatstepsanduntilall

theairiscompletelypurgedfromthesystem.

Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverse

atnormalspeeds,thenthetransaxleisconsidered

purged.

DoNotchangehydraulicsystemoil(exceptforwhat

canbedrainedwhenchanginglter),unlessitisfeltthe

oilhasbeencontaminatedorbeenextremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

MowerMaintenance

ServicingtheCuttingBlades

ServiceInterval:Beforeeachuseordaily

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch,andmovethemotioncontrollevers

outwardtotheneutralpositionandengageparking

brake.Stoptheengine,removethekey,anddisconnect

thesparkplugwire(s)fromthesparkplug(s).

InspectingtheBlades

1.Inspectthecuttingedges(Figure38).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades;refertotheSharpeningtheBladessection.

2.Inspecttheblades,especiallythecurvedarea.Ifyou

noticeanydamage,wear,oraslotforminginthis

area(item3inFigure38),immediatelyinstallanew

blade.

36

Loading...

Loading...