25

Nominal dia.

Max. interval (m)

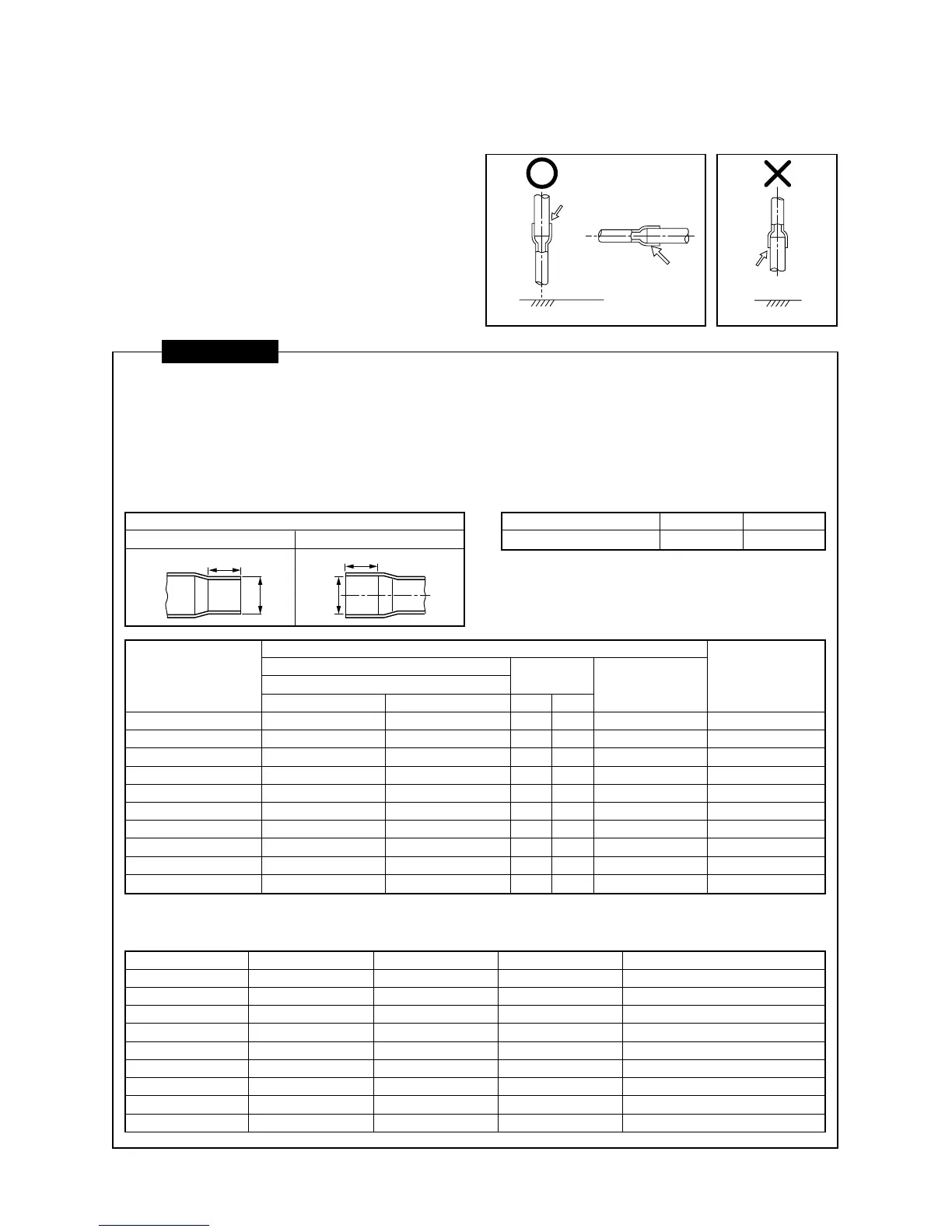

5-10. Brazing Work

1. Brazing work should be performed downwards

or sideways. Avoid brazing upwards (in order to

avoid incomplete brazing). (Recommendation)

2. Always used the specified piping materials for

liquid pipes and gas pipes, and make sure that

they are installed in the proper direction and at

the proper angle.

3. The “nitrogen gas blow” method should be used

when brazing.

CAUTIONS

1. Pay attention to fire prevention concerns. (Take preventative measures in the area where brazing work is to

be performed, such as keeping a fire extinguisher or water handy.)

2. Be careful not to burn yourself.

3. Make sure that any gaps between pipes and couplings are appropriate. (Do not miss brazing any joints.)

4. Make sure that pipes are adequately supported.

• The following table provides basic guidelines for the interval between supports for horizontal copper pipe.

Interval between supports for copper pipe

• Avoid securing copper pipes with metal brackets

directly.

* Gas brazing of refrigerant pipes must be performed by personnel qualified to do so under local ordinances.

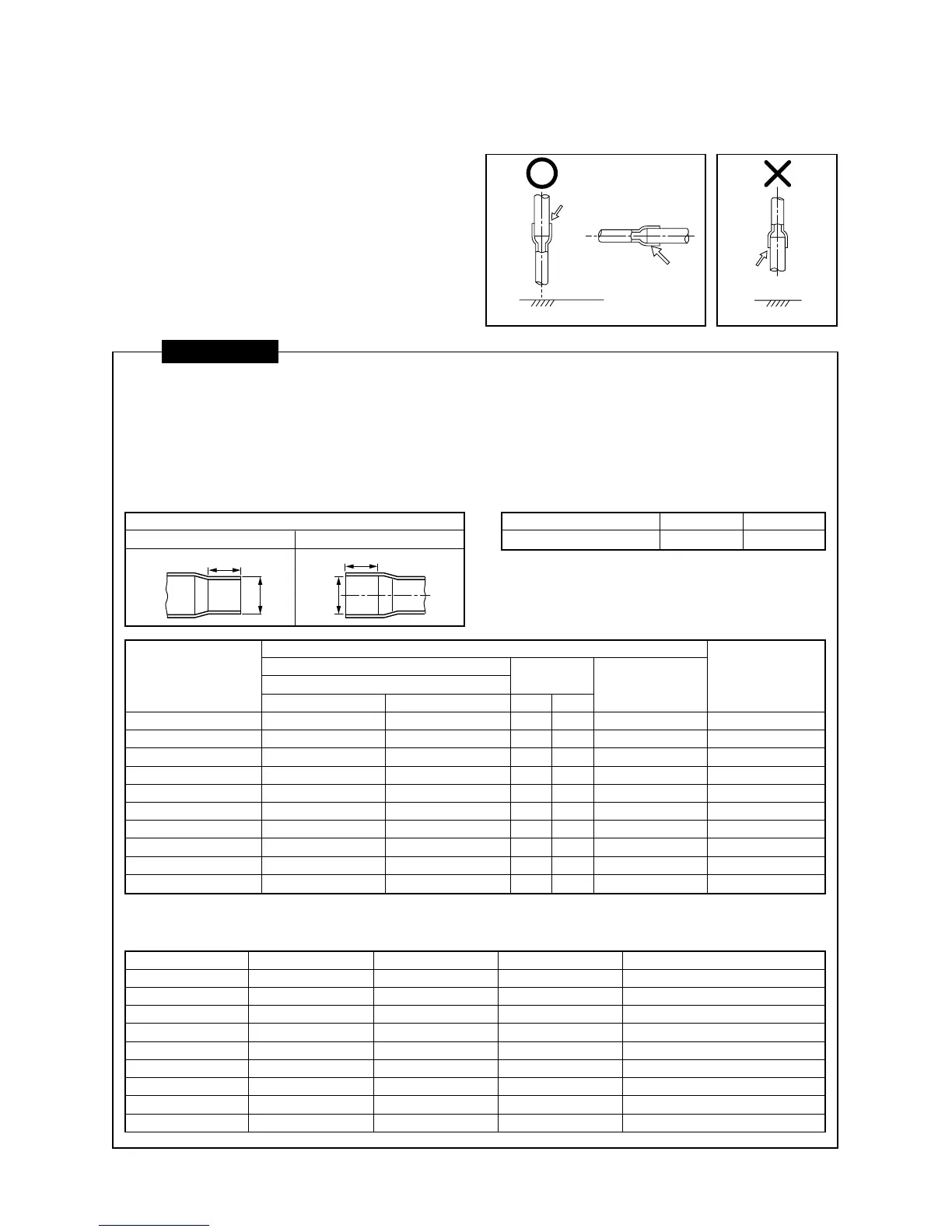

Minmum wall thickness for R410A application

Brazing material

Brazing

material

Lateral direction

Brazing

material

(Direction downward) (Direction upward)

(Recommended brazing)

Coupling size of brazed pipe

Standard outer dia. of

connected copper pipe

6.35

9.52

12.70

15.88

19.05

22.22

28.58

34.92

38.10

41.28

External size Internal size

Standard outer dia. (Allowable difference)

CF

6.35 (±0.03) 6.45 ( )

9.52 (±0.03) 9.62 ( )

12.70 (±0.03) 12.81 ( )

15.88 (±0.03) 16.00 ( )

19.05 (±0.03) 19.19 ( )

22.22 (±0.03) 22.36 ( )

28.58 (±0.04) 28.75 ( )

34.90 (±0.04) 35.11 ( )

38.10 (±0.05) 38.31 ( )

41.28 (±0.05) 41.50 ( )

Min. depth

of insertion

KG

76

87

98

98

11 10

11 10

13 12

14 13

15 14

15 14

Oval value

0.06 or less

0.08 or less

0.10 or less

0.13 or less

0.15 or less

0.16 or less

0.20 or less

0.25 or less

0.27 or less

0.28 or less

Min. thickness

of coupling

0.50

0.60

0.70

0.80

0.80

0.82

1.00

1.20

1.26

1.35

+0.04

–0.02

+0.04

–0.02

+0.04

–0.02

+0.04

–0.02

+0.03

–0.03

+0.03

–0.03

+0.06

–0.02

+0.04

–0.04

+0.08

–0.02

+0.08

–0.02

Connected section

(Unit: mm)

Connected section

External size Internal size

20 or less 25 to 40

1.0 1.5

Soft (Coil)

¡

¡

¡

¡

NG

NG

NG

NG

NG

Hard or Half hard

¡

¡

¡

¡

¡

¡

¡

¡

¡

OD (Inch)

1/4

3/8

1/2

5/8

3/4

7/8

1.1/8

1.3/8

1.5/8

OD (mm)

6.35

9.52

12.70

15.88

19.05

22.20

28.58

34.92

41.28

Minium wall thickness

0.80

0.80

0.80

1.00

1.00

1.00

1.00

1.10

1.25

K

ØC

G

ØF

Loading...

Loading...