E6581611

E-11

5

[Using a VF motor (motor for use with inverter)]

Setting of electronic thermal protection characteristics selection

Setting value Overload protection Overload stall

valid invalid

valid valid

invalid invalid

invalid valid

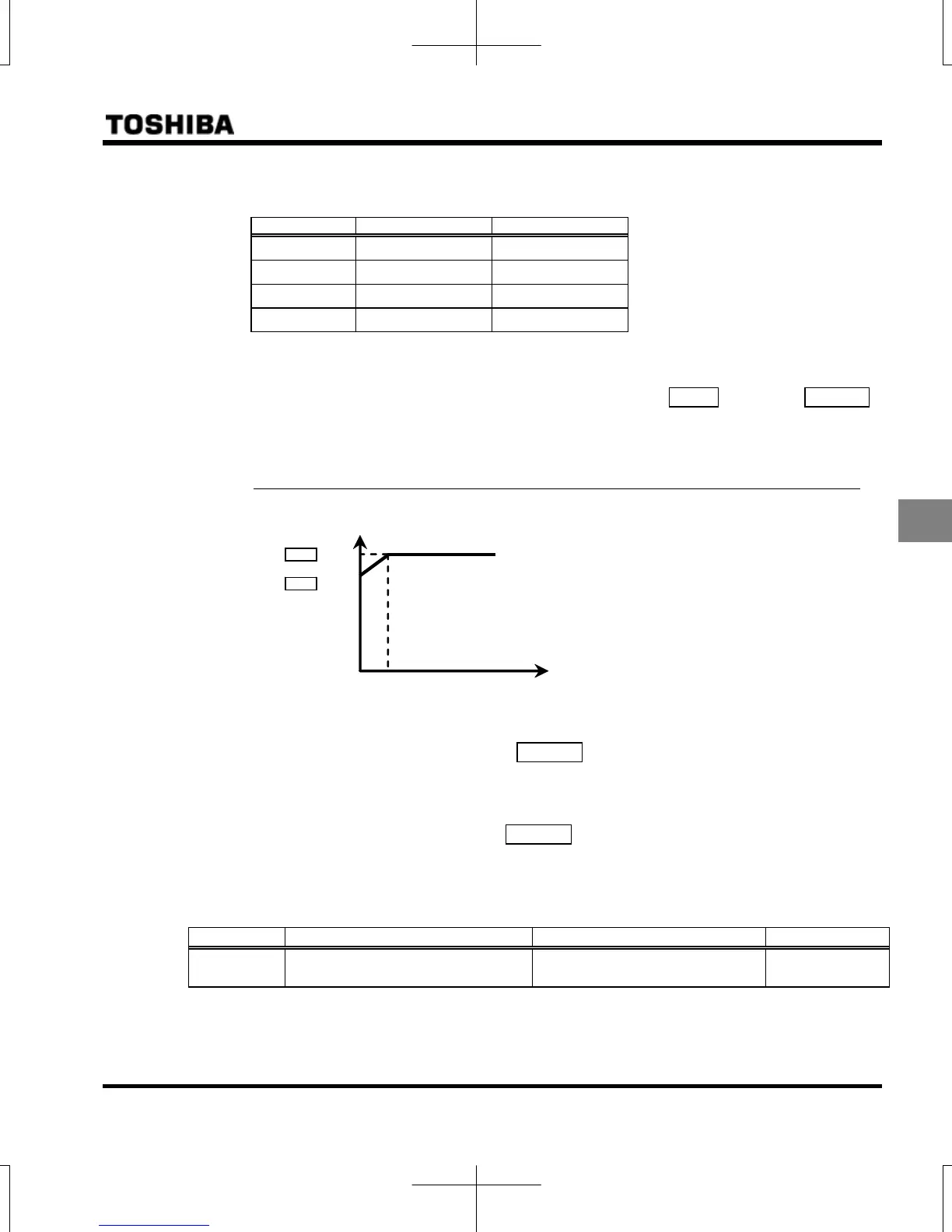

VF motors (motors designed for use with inverters) can be used in frequency ranges lower than those

for standard motors, but their cooling efficiency decreases at frequencies below 6Hz.

Setting of motor electronic thermal protection level 1 (Same as f173)

If the capacity of the motor is smaller than the capacity of the inverter, or the rated current of the motor

is smaller than the rated current of the inverter, adjust the electronic thermal protection level 1 so

that it fits the motor's rated current.

* If the indications are in percentages (%), then 100% equals the inverter's rated output current (A).

×1.0

Output frequency (Hz)

Output current reduction factor [%]

/

[A]

0

Note) The start level for motor overload reduction is fixed at 6 Hz.

6Hz

×0.6

2) Motor 150%-overload detection time f607

Parameter f607 is used to set the time elapsed before the motor trips under a load of 150% (overload trip

2) within a range of 10 to 2400 seconds.

3) Inverter overload detection method f631

As this function is set to protect the inverter unit, this function cannot be turned off by parameter setting.

The inverter overload detection method can be selected using parameter f631 (Inverter overload

detection method).

[Parameter setting]

Title Function Adjustment range Default setting

f631 Inverter overload detection method

0: 150%-60s (120%-60s)

1: Temperature estimation

0

If the inverter overload trip function (ol1) is activated frequently, this can be improved by adjusting the stall

operation level f601 downward or increasing the acceleration time acc or deceleration time dec.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Loading...

Loading...