Installation

Page 20 RES-403

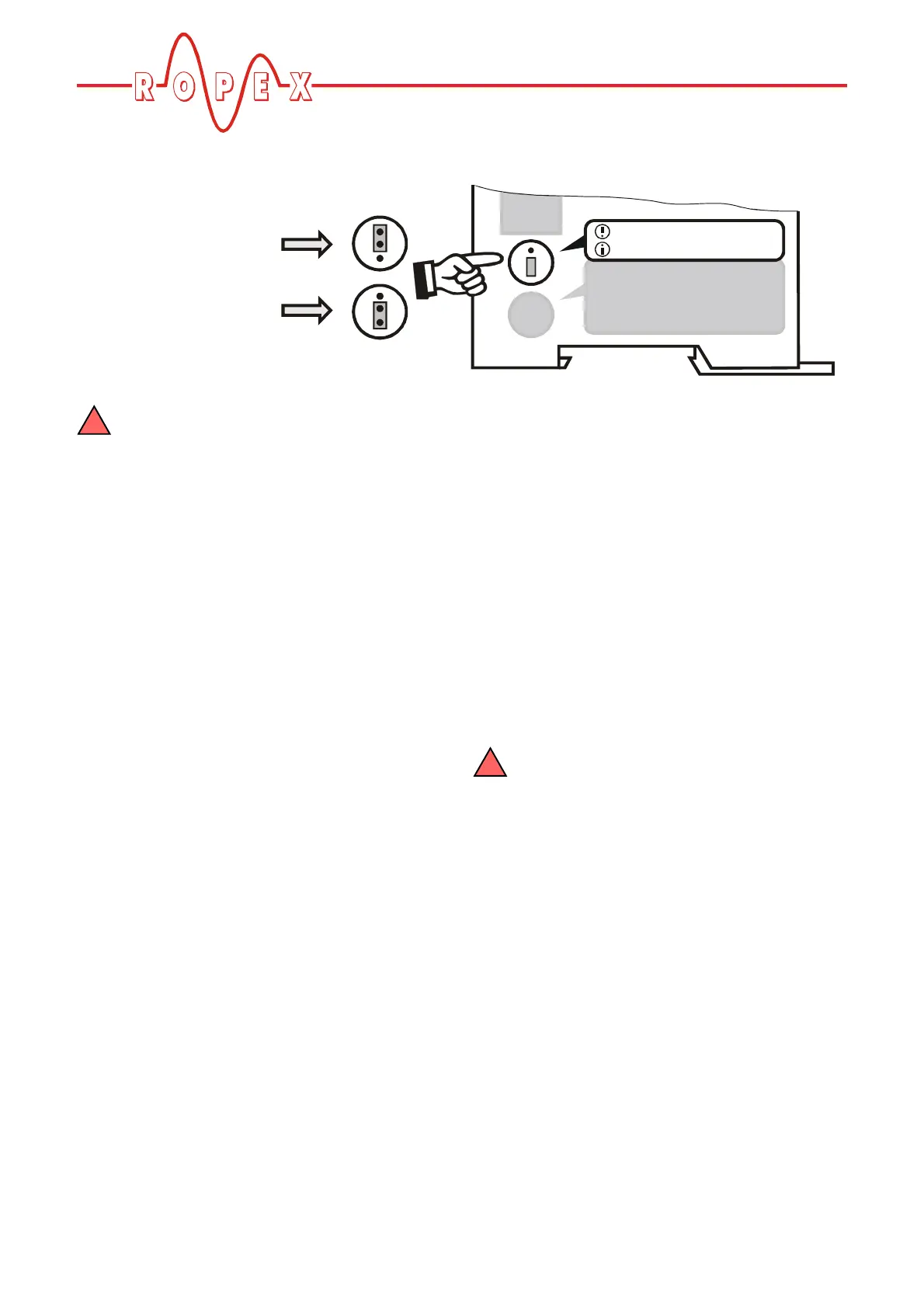

8.11.3 Configuration of the alarm relay

If the plug-jumper is not inserted - or if it is

incorrectly inserted - an error message

appears when the controller is switched on

(ª

ªª

ª section 9.12 "Error messages" on page 31).

If the "Alarm output opened by alarm/PC CONFIGURA-

TION" position is selected (as of October 2005), the

behavior of the alarm output can be configured in more

detail by means of the ROPEX visualization software

(ª see section 9.10 "Diagnostic interface/visualization

software (as of October 2005)" on page 30).

8.12 Replacing and "burning in" the

heatsealing band

8.12.1 "Burning in" the heatsealing band

The heatsealing band is a key component in the control

loop, since it is both a heating element and a sensor.

The geometry of the heatsealing band is too complex to

be discussed at length here. We shall therefore only

refer to a few of the most important physical and elec-

trical properties:

The measuring principle applied for this system neces-

sitates a heatsealing band alloy with a suitable tempe-

rature coefficient TCR. Too low a TCR leads to oscilla-

tion or uncontrolled heating.

When heatsealing bands with a higher TCR are used,

the controller must be calibrated for this.

The first time the heatsealing band is heated to appro-

ximately 200…250 °C, the standard alloy undergoes a

once-only resistance change (burn-in effect). The cold

resistance of the heatsealing band is reduced by appro-

ximately 2…3%. However, this at first glance slight

resistance change results in a zero point error of

20…30°C. The zero point must therefore be corrected

after a few heating cycles, i.e. the AUTOCAL function

must be repeated.

The burn-in effect described here does not occur if the

heatsealing band has already been thermally pret-

reated by the manufacturer.

An overheated or burned-out heatsealing

band must no longer be used because the

TCR has been altered irreversibly.

One very important design feature is the copper or

silver-plating of the heatsealing band ends. Cold ends

allow the temperature to be controlled accurately and

increase the life of the teflon coating and the heat-

sealing band.

0

5

1

2

3

4

6

7

8

9

Alarm relay contact

opened by alarm/

PC-CONFIGURATION.

Alarm relay contact

closed by alarm.

(factory setting)

CONFIGURATION

ALARM OUTPUT

DE-ENERGIZED / PC

AT ALARM

ENERGIZED

!

!

Loading...

Loading...