9

11UNT-PRC002-GB

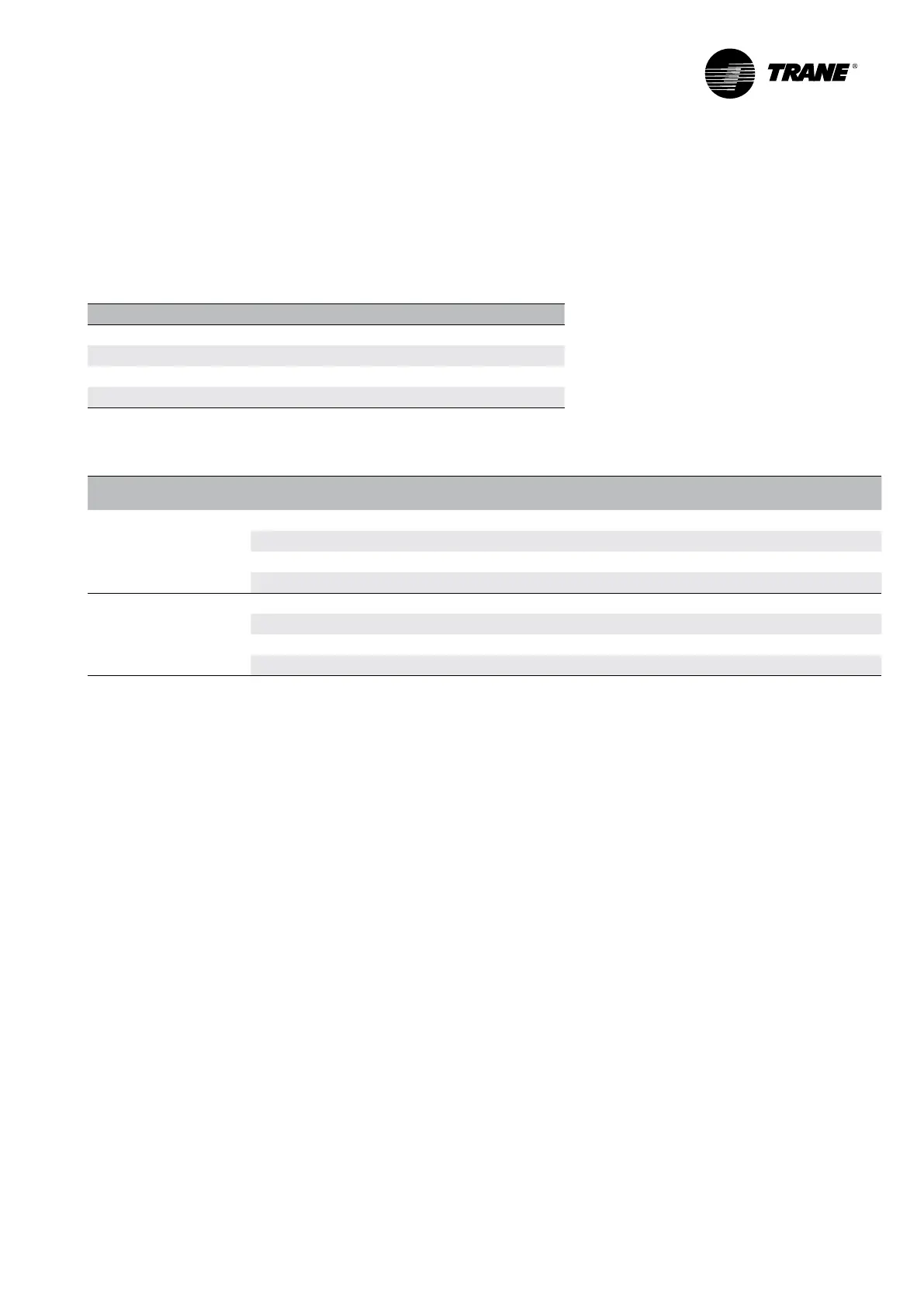

Sound power levels

Discharge

Measurement conditions:

Measurements taken in a room adjacent to the room containing the FWD, at the outlet of the rectangular duct (1.5 m

long) fixed to its discharge opening.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 55 50 42 37 37 31 30 46

FWD 08 2 57 54 47 40 30 38 40 50

3 58 57 50 42 32 40 43 53

1 57 51 45 42 34 33 28 48

FWD 10 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 57 51 45 42 34 33 28 48

FWD 12 2 58 54 48 45 38 39 35 51

3 60 58 50 48 40 42 39 54

1 56 62 50 48 39 38 36 56

FWD 14 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

1 57 63 51 49 40 39 37 57

FWD 20 2 61 66 55 53 47 46 45 60

3 63 69 58 56 50 50 49 63

Intake

Measurement conditions:

Measurements taken at the horizontal air intake.

Fan Power level in dB(A), per Hz frequency band Overall power

Unit speed 125 250 500 1000 2000 4000 8000 dB(A)

1 56 55 55 53 46 45 42 57

FWD 08 2 63 62 60 60 53 53 53 64

3 66 65 63 62 56 55 57 67

1 62 58 55 58 51 48 44 61

FWD 10 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 62 58 55 58 51 48 44 61

FWD 12 2 66 63 60 62 56 55 52 66

3 70 67 63 65 59 59 57 69

1 66 65 65 65 57 50 46 68

FWD 14 2 73 72 69 71 64 59 57 74

3 78 76 73 75 69 64 63 78

1 68 72 64 64 56 52 50 69

FWD 20 2 76 76 68 71 65 61 61 75

3 78 79 71 74 69 66 66 78

CG-SVU010C-GB

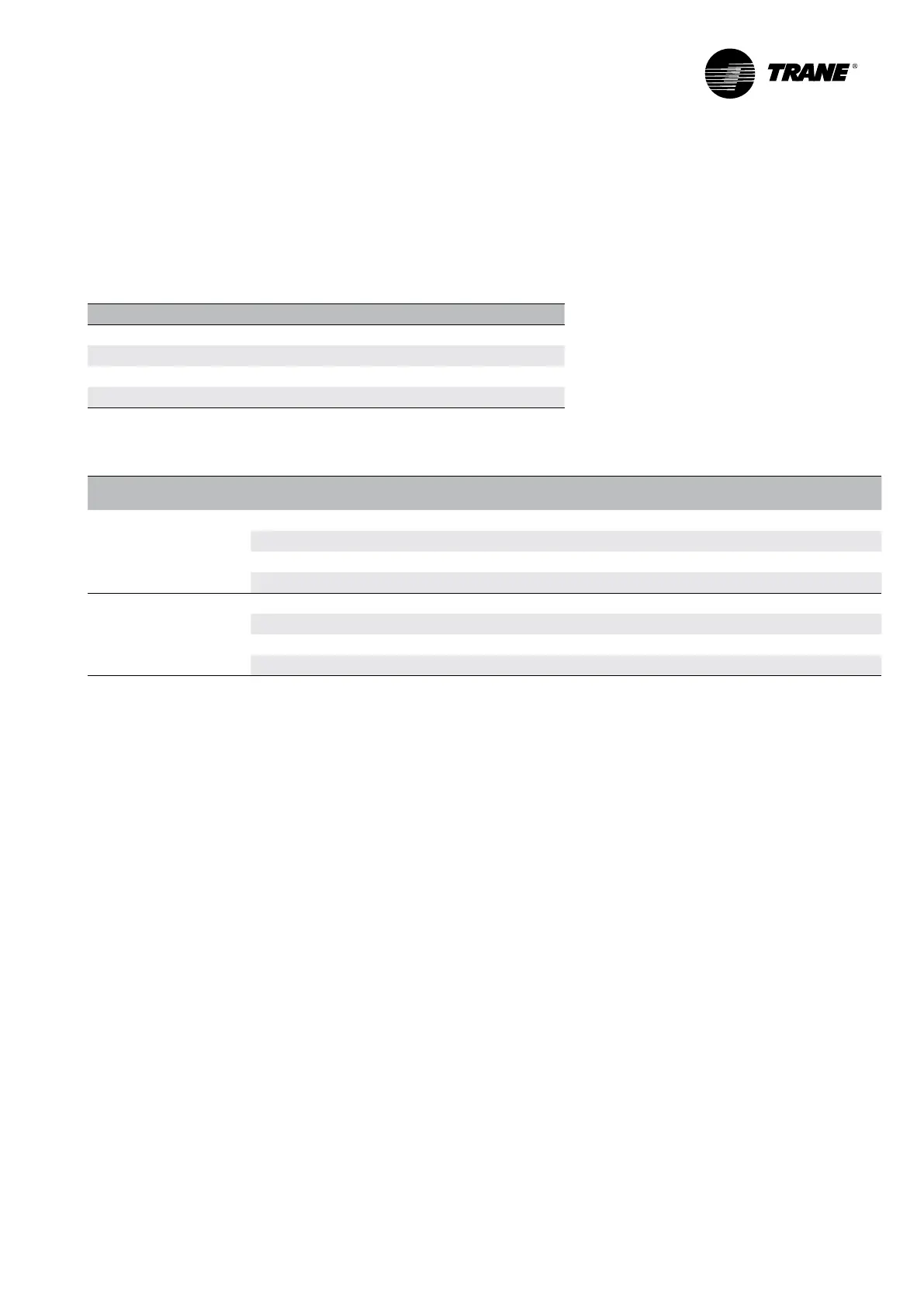

Relay Assignments Using Tracer™ TU

Tracer™ TU Service Tool is used to install the Programmable Relay Option package and assign any of the above lists

of events or status to each of the four relays provided with the option. (See “Tracer™ TU,” for more information on

the Tracer TU service tool) The relays to be programmed are referred to by the relay’s terminal numbers on the LLID

board 1A18.

The default assignments for the four available relays of the Programmable Relay option are:

Table 3 –

Programmable Relay option Default assignments

Relay

Relay 0 Terminals J2 - 1,2,3: Evaporator Freeze Avoidance Request

Relay 1 Terminals J2 - 4,5,6: Maximum Capacity

Relay 2 Terminals J2 - 7,2,3: Compressor Running

Relay 3 Terminals J2 – 10,11,12: Latching Alarm

The eight available relays in the Lead/Lag Chiller Sequence Option are assigned with the following defaults as follows:

Table 4 –

Lead/Lag Chiller Sequence Option Default assignments

LLID Name

LLD Software

Relay Designation

Output Name Default

Operating Status

Programmable Relays

Module 1

Relay 0 Status Relay 1, J2-1,2,3 Evaporator Water Freeze Avoidance Request

Relay 1 Status Relay 2, J2-4,5,6 Maximum Capacity

Relay 2 Status Relay 3, J2-7,8,9 Compressor Running

Relay 3 Status Relay 4, J2-10,11,12 Latching Alarm

Operating Status

Programmable Relays

Module 2

Relay 4 Status Relay 5, J2-1,2,3 Alarm Ckt 2

Relay 5 Status Relay 6, J2-4,5,6 Alarm Ckt 1

Relay 6 Status Relay 7, J2-7,8,9 Alarm (Latching or Non latching)

Relay 7 Status Relay 8, J2-10,11,12 Non Latching Alarm

If any of the Alarm/Status relays are used, provide electrical power, 115 VAC with fused-disconnect to the panel

and wire through the appropriate relays (terminals on 1A10). Provide wiring (switched hot, neutral, and ground

connections) to the remote annunciation devices. Do not use power from the chiller’s control panel transformer

to power these remote devices. Refer to the field diagrams which are shipped with the unit.

Loading...

Loading...