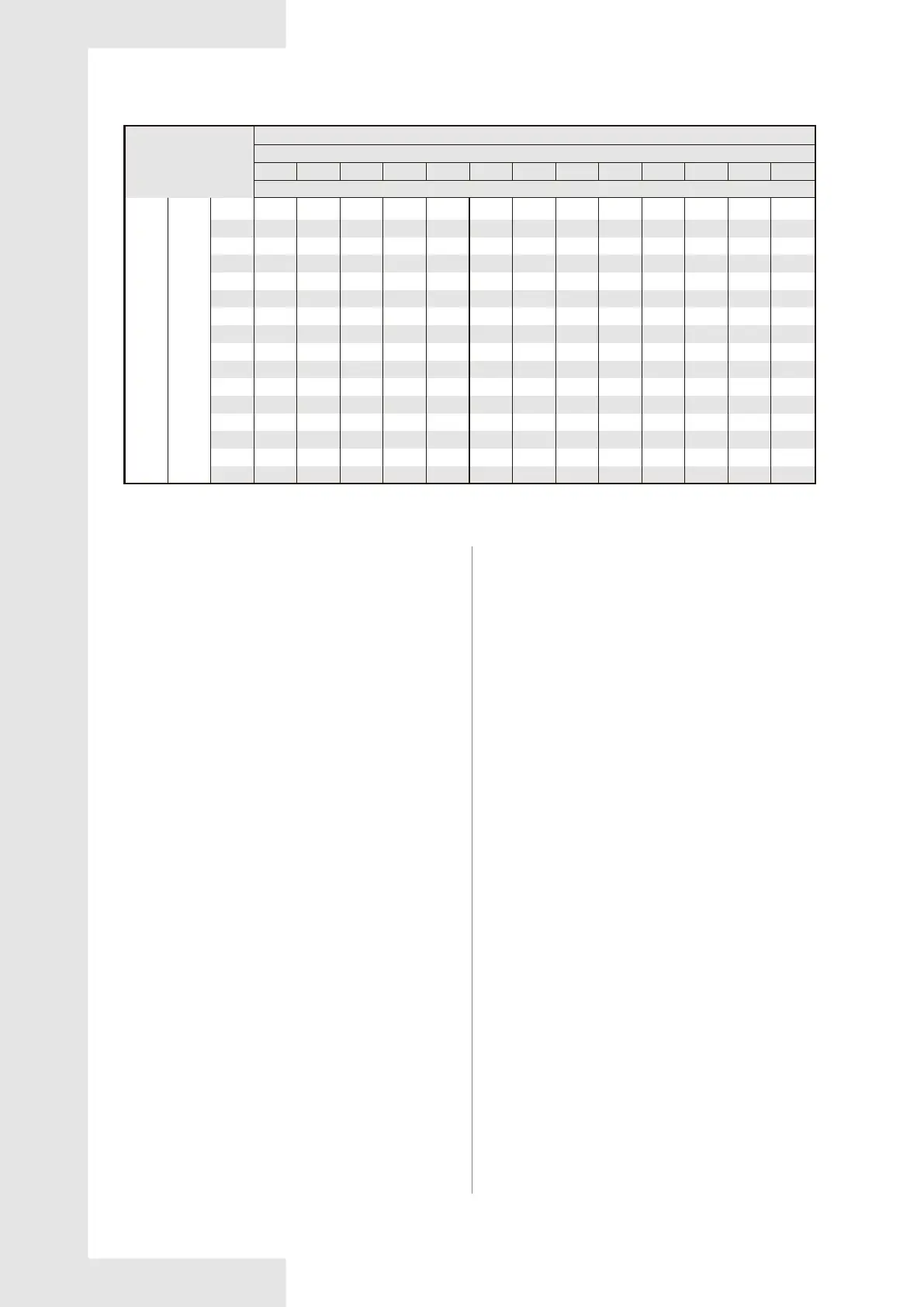

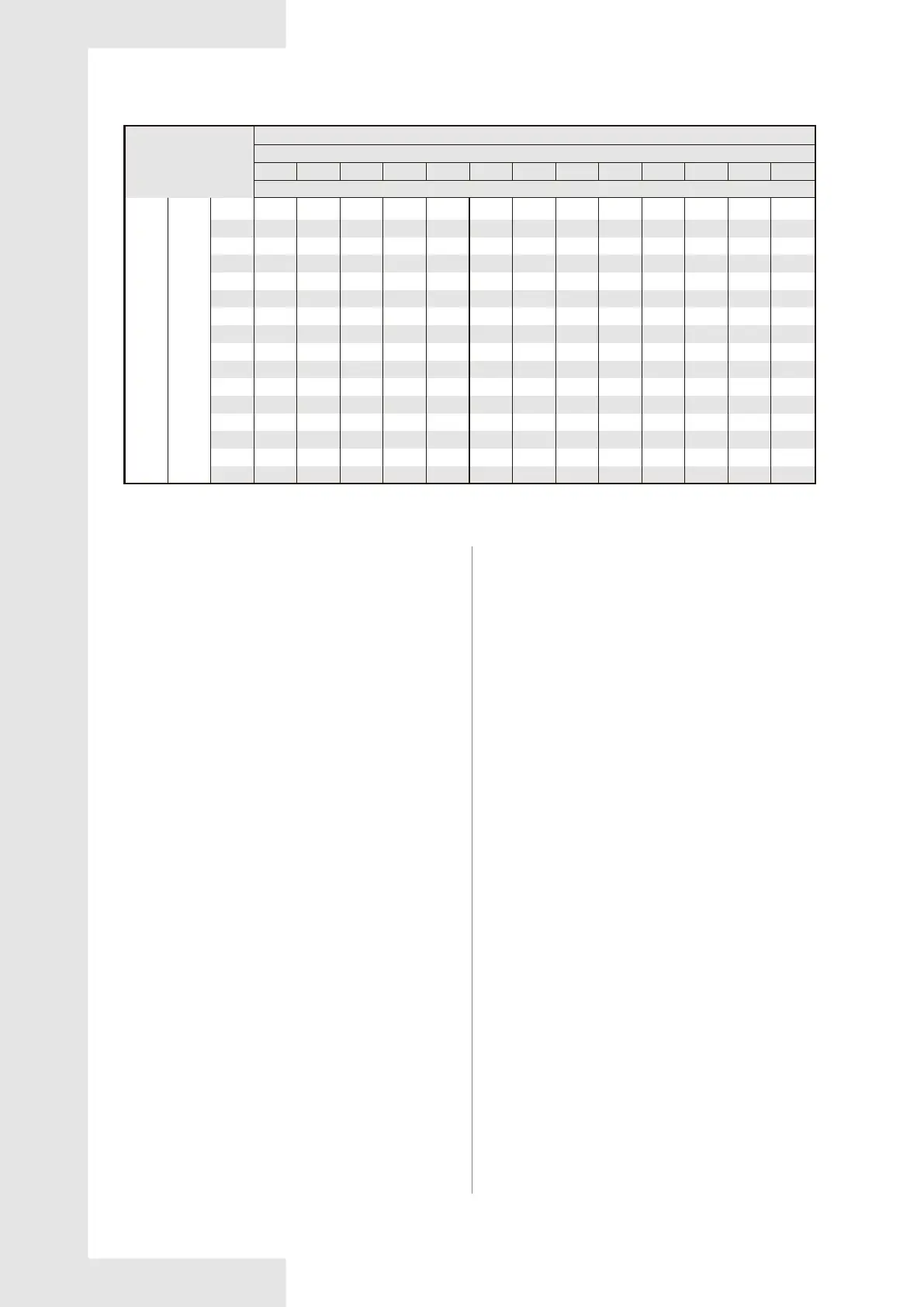

Table 7-15 Refrigerant charge for H/P system

135

128

121

114

107

100

93

86

79

72

65

58

51

44

37

30

431

405

379

354

328

302

291

280

270

259

248

439

413

387

361

335

309

298

287

276

265

254

447

421

395

368

342

316

305

294

282

271

260

455

429

402

376

349

323

312

300

289

277

266

463

436

410

383

357

330

318

307

295

284

272

265

471

444

417

391

364

337

325

313

302

290

278

271

264

479

452

425

398

371

344

332

320

309

297

285

278

271

264

487

460

433

405

378

351

339

327

316

304

292

285

278

271

264

495

468

440

413

385

358

346

334

323

311

299

292

285

278

271

503

475

448

420

393

365

353

341

330

318

306

299

292

285

278

511

483

455

428

400

372

360

348

337

325

313

306

299

292

285

518

490

462

435

407

379

367

355

344

332

320

313

306

299

292

Heating Charge Chart/Tableau De Charge de Chauffage60

Heating Mode

Mode

De Chauffage

Indoor Dry Bulb Temperature(oF)/Temperature Interieur au Themometre sec(en oF)

Low Pressure Service Port(psig)

Vanne Détectée de Pression Basse(en psig)

High Pressure Service Port(psig)/Vanne Détecté de Pression Haute(en psig)

60 62 64 66 68 70 72 74 76 78 80 82

8.1 Compressor Crankcase Heater

(Optional)

8.2 Protection

8.3 Defrost Mode Introduction

(Heat Pump Only)

8.2.1 Protection for HP system

8 SYSTEM OPERATION

Refrigerant migration during the off cycle can result in a

noisy start up. Add a crankcase heater to minimize

refrigeration migration, and to help eliminate any start up

noise or bearing “wash out”.

All heaters are located on the lower half of the

compressor shell. Its purpose is to drive refrigerant from

the compressor shell during long off cycles, thus

preventing damage to the compressor during start-up.

At initial start-up or after extended shutdown periods,

make sure the heater is energized for at least 12 hours

before the compressor is started. (Disconnect switch on

and wall thermostat off.)

The crankcase heater will start up or shut down

according to the following logic:

The crankcase heater will start up when the compressor

is off and T4<41°F.

The crankcase heater will shut down when T4 ≥ 45 °F

In any condition, the crankcase heater will shut down

when the compressor is on

If sensors(T3&T4) become open-circuit or short-circuit,

the compressor ,outdoor fan motor and reversing valve

circuit will shut down.

Discharge temperature protection:

If discharge temp. is > 239°F, the compressor will shut

down, If discharge temp. is < 167°F, the compressor will

resume operation.

High pressure protection

If high pressure is >609PSIG,the compressor and the

outdoor fan motor will stop running.

If high pressure is <464PSIG,the compressor and the

outdoor fan motor will resume running(3 minutes delay

necessary ).

Low pressure protection

When low pressure is <21PSIG,the compressor and

the outdoor fan motor will stop running.

When low pressure is >44PSIG,the compressor and

the outdoor fan motor will resume running(3 minutes

delay necessary ).

In stand-by status, if low pressure protection was

detected, the compressor will not start.

If protection cycles occur four times within 30 minutes,

the compressor and outdoor fan will shut down. In this

condition, the system needs to power on once more in

order to keep on working.

T4 function:

When T4 is < 5 °F, the compressor will stop. If the

electrical heater kit is installed in the indoor unit, the

outdoor unit will send the operation signal to the indoor

unit.

When T4 is > 10.4 °F, the compressor will restart .

Manual defrost mode

To manually cycle the defrost mode, set switch SW3-1

to the “ON” position (See Fig 8-1). The system will

engage a defrost cycle, and automatically exit defrost

mode once the Shut-down conditions of defrost mode

described below are met.

Caution: Once the manual defrost mode is finished,

please set switch SW3-1 back to “OFF”.

20

Loading...

Loading...