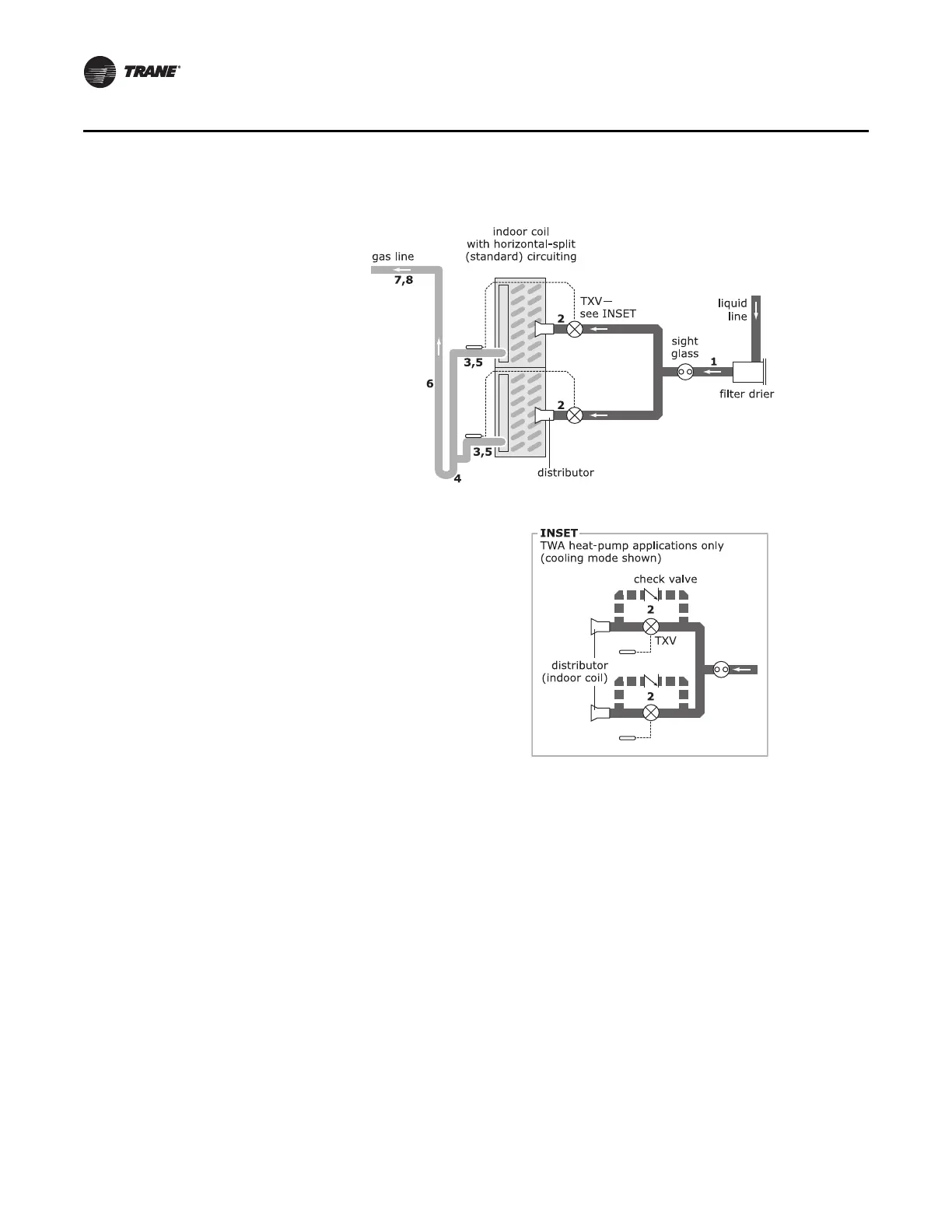

Figure 8. Indoor coil with two distributors (single-circuit TTA/TWA units)

1 Pitch the liquid line 1 inch per 10 feet (1 cm per

3 m) so that the liquid refrigerant drains toward

the indoor coil. Use the liquid-line size

recommended in Table 3, p. 16.

2 Provide one expansion valve (TXV)

per distributor.

TWA heat pumps only: Provide one check

valve for each expansion valve.

3 Pitch the gas line leaving the coil so that it

slopes away from the coil by 1 inch per 10 feet

(1 cm per 3 m).

4 Arrange the gas line so that suction gas leaving

the coil flows downward, past the lowest gas-

header outlet, before turning upward. Use a

double-elbow configuration on all lower branch

circuits to isolate the TXV bulb from suction-

header conditions. See “Gas Line: Routing,” p. 7.

5 For all coil branch circuits in the gas line, use a

tube diameter that is one size smaller than the

gas-line size recommended in Table 3, p. 16.

6 For vertical risers, use the tube diameter

recommended in Table 3, p. 16. Ensure that the

top of the riser is at least 1 foot (30 cm) above

the lowest point.

7 Pitch the gas line by 1 inch per 10 feet (1 cm per

3 m) toward the indoor coil.

8 Insulate the gas line.

Loading...

Loading...