32 LPC-SVX01C-EN

mechanical

requirements

Installation

Coil Connection Recommendations

Follow these recommendations to

prevent possible damage when making

coil connections:

1. Install a ½”15 swing-check vacuum

breaker in the unused condensate

return connection at the top of the

coil. Install this vacuum breaker as

close to the coil as possible.

2. Vent the vacuum breaker to the

atmosphere or pipe it to the return

main at the discharge side of the

steam trap.

Note: A vacuum breaker is mandatory

when the coil is controlled by a modulat-

ing steam supply or two-position (on/off)

automatic steam supply valve.

WARNING

Hazardous Pressures!

If a heat source is required to raise

the tank pressure during removal of

refrigerant from cylinders, use only

warm water or heat blankets to raise

the tank temperature. Do not exceed

a temperature of 150

°

F. Do not, under

any circumstances apply direct

flame to any portion of the cylinder.

Failure to follow these safety pre-

cautions could result in a violent ex-

plosion, which could result in death

or serious injury.

The condensate return line must be

piped full size of the condensate trap

connection, except for a short nipple

screwed directly into the coil headers

condensate return trapping. Do not bush

or reduce the coil return tapping size.

Proper Steam Trap Installation

Proper steam trap selection and

installation is necessary for satisfactory

coil performance and service life. For

installation, use the following steps:

1. Install the steam trap discharge 12

inches below the condensate return

connection to provide sufficient head

pressure to overcome trap losses

and ensure complete condensate

removal. Use float and themostatic

traps with atmospheric pressure

gravity condensate return, with

automatic controls or when there is a

possibility of low pressure steam.

Float and thermostatic traps are

recommended because gravity drain

and continuous discharge operation.

2. Trap each coil separately to prevent

holding up condensate in one or

more of the coils.

3. Install strainers as close as possible

to the inlet side of the trap.

4. Use a V-Port modulating valve to

obtain gradual modulation of the coil

steam supply.

5. Do not modulate systems with

overhead or pressurized returns

unless the condensate is drained by

gravity into a receiver, vented to

atmosphere, and returned to the

condensate pump.

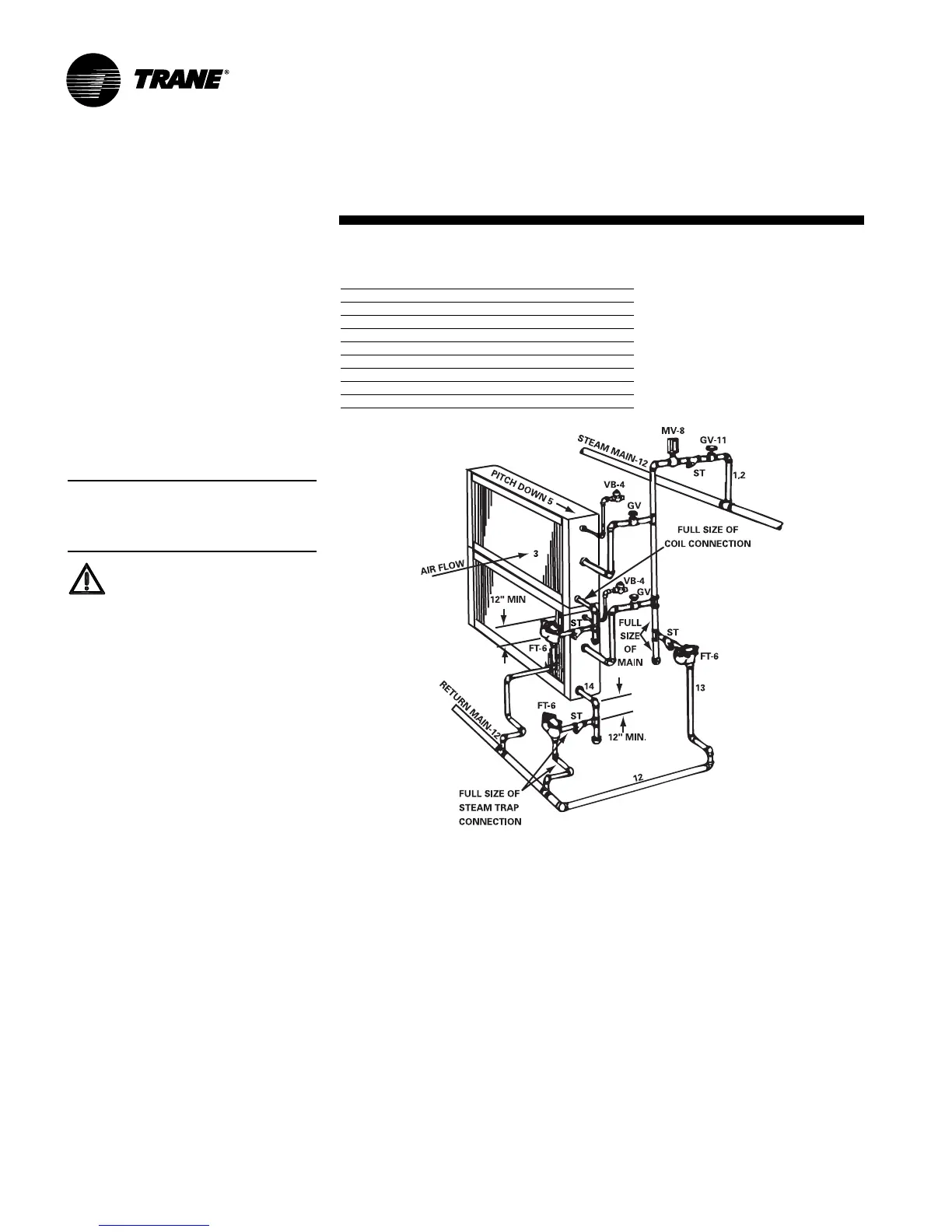

Figure I-MR-2. Typical Piping for Steam Coils

Code of System Components in Piping Diagram

FT Float and thermostatic steam trap

BT Bucket steam trap

GV Gate valve

OV Automatic two-position (on-off) control valve

TV Automatic three-way control valve

VB Vacuum breaker

CV Check valve

ST Strainer

AV Automatic or manual air vent

6. Slowly turn the steam on full for at

least ten minutes before opening the

fresh air intake on units with fresh air

dampers.

7. Pitch all supply and return steam

piping down 1-inch per 10 feet in the

direction of the steam or condensate

flow.

8. Do not drain the steam mains or

take-offs through the coils. Drain the

mains ahead of the coil through a

steam trap to the return line.

9. Assure continuous condensate

removal. Overhead returns require

one psig of pressure at the steam

trap discharge for each two feet of

elevation.

Loading...

Loading...