SS-APG008H-EN

23

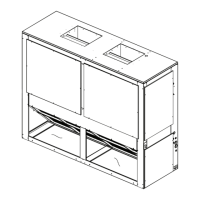

Figure 14. Type UF evaporator coil with four distributors

thermal expansion

valves (TXV)

liquid

line

filter drier

sight

glass

distributor

suction line

Evaporator Coil

with Horizontal-Split

(Standard) Circuiting

thermal expansion

valves (TXV)

liquid

line

filter drier

sight

glass

distributor

suction line

Evaporator Coil with

Intertwined Circuiting

Notes:

1. Pitch the liquid line 1 inch per 10 feet (1 cm per 3 m) so that the liquid refrigerant drains toward the indoor coil. Use

the liquid-line size recommended in Table 2, p. 25, or Table 3, p. 26.

2. Provide one expansion valve (TXV) per distributor.

TWA heat pumps only: Provide one check valve for each expansion valve.

3. Pitch the gas line leaving the coil so that it slopes away from the coil by 1 inch per 10 feet (1 cm per 3 m).

4. Use the DETINT to prevent oil and refrigerant migration when the unit is off. The DETINT also serves to isolate the

TXV bulb from suction-header conditions. See “Line Sizing, Routing, and Component Selection,” p. 9.

5. For all coil branch circuits in the gas line, use a tube diameter that is one size smaller than the gas-line size

recommended in Table 2, p. 25 or Table 3, p. 26.

6. For vertical risers, use the tube diameter recommended in the Component selection tables, found in Table 2, p. 25,

or Table 3, p. 26. Ensure that the top of the riser is at least 1 foot (30 cm) above the lowest point.

7. Pitch the gas line 1 inch per 10 feet (1 cm per 3 m) toward the indoor coil.

8. Insulate the gas line.

Refrigerant Piping Examples

Loading...

Loading...