Do you have a question about the Trane Odyssey TWA0724 A Series and is the answer not in the manual?

Defines advisory types including warnings, cautions, and notices.

Discusses ozone layer impact of chemicals and refrigerant handling.

Covers refrigerant handling rules and technician certification.

Emphasizes qualified personnel and code compliance for safety.

Mandates safety gear for hazardous tasks to prevent injury.

Explains the model naming convention for heat pump condensers.

Details the meaning of each digit in the unit model number.

Describes the two-compressor options and energy saving features.

Covers checking for damage and verifying unit details upon receipt.

Details steps for checking refrigerant circuits for leaks.

Safety and operational requirements for unit placement and lifting.

Discusses structural requirements for roof installation safety.

Guidelines for ground installation and snowy regions.

Verifies proper installation and leak testing of refrigerant lines.

Confirms power, thermostat, and low voltage connections.

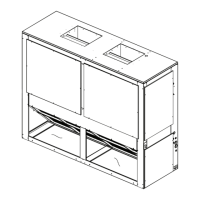

Provides dimensional data for various heat pump models.

Details measurements and clearances for single compressor models.

Details measurements and clearances for dual compressor models.

Provides measurements and clearances for specific 8.33 & 10 ton models.

Details measurements for specific 8.33 & 10 ton dual compressor models.

Provides measurements for larger dual compressor units (13-20 ton).

Lists shipping and net weights for various R-410A and R-22 models.

Illustrates designated points for lifting various unit models.

Details allowable elevation differences for refrigerant piping.

Guides connection and preparation of outdoor unit piping.

Covers connecting indoor lines and performing leak tests.

Covers vacuum procedures and approved oils for units.

Guidelines for insulating suction and liquid lines.

Details how to charge refrigerant into the system.

Provides estimated charge levels and line sizes for various models.

Steps for charging refrigerant in liquid form.

General guidance on field wiring requirements.

Covers power connections, grounding, and low voltage wiring.

Details jobsite connections for Symbio system controls.

Provides guidance on wiring connections between units.

Details wiring for Symbio heat pump with constant volume air handler.

Details wiring for Symbio heat pump with SZVAV/2-Speed AHU.

Illustrates refrigerant path during cooling operation.

Illustrates refrigerant path during heating operation.

Describes various safety and operational controls in the system.

Warns about hazards when working with live electrical components.

Explains how to use the service test mode for diagnostics.

Lists routine checks for monthly inspections.

Outlines required checks at the start of the cooling season.

Details procedures for cleaning condenser and evaporator coils.

Provides a template for recording maintenance inspection data.

Lists charging curves and pressure tables for TWA models.

Maps part numbers to wiring diagram descriptions and applicability.

Maps part numbers to device location print applicability.

Lists the equipment and accessories included in the warranty.

Outlines the warranty period and coverage for defects.

Details what is not covered by the warranty.

| Type | Split System Air Conditioner |

|---|---|

| Cooling Capacity | 72, 000 BTU/h |

| Refrigerant Type | R-410A |

| Voltage | 208/230V |

| Phase | 3 |

| Sound Level (Indoor) | Not Available |

Loading...

Loading...