54

RT-SVX075C-EN

a. < 1.5 Vdc (0% ModBus Firing Rate)]: OFF

b. 1.5 – 2.0 Vdc (0.5% ModBus Firing Rate): Minimum

fire (Manifold pressure .20 to.30 in. w.c.)

c. 2.1 – 6.0 Vdc (1 - 56% ModBus Firing Rate):

Modulation linearized to firing rate (Modulating

Section Manifold pressure .25 to 3.50 in. w.c.)

9. If heating demand continues to increase and the analog

input signal exceeds 6.0 Vdc (56% ModBus firing rate),

and provided the air pressure switch is closed, the

VB1285 initiates a trial for ignition of the 2

nd

stage.

10. Burners ignite and cross light. Flame is sensed and

control continues the heating cycle.

11. Once the 2

nd

stage operation is verified, the 1

st

stage

modulation is reset to its minimum input rate.

12. The modulating gas valve is set as commanded by the

analog FIRING RATE input signal and will modulate

between 6.1 and 10.0 Vdc analog input (57 - 100%

ModBus firing rate), while maintaining operation of the

2

nd

stage at 3.50–inches w.c. manifold pressure.

13. The control remains in the high fire mode as long as the

firing rate signal is above 5.0 Vdc (46% ModBus firing

rate).

14. If the firing rate signal drops below 5.0 Vdc (46%

ModBus firing rate), the 2

nd

stage section will shut-off

and the 1

st

stage will continue to operate and modulate

in response to changes in analog signal voltage.

15. System will continue in the run state until the heat

enable contacts open or the analog input signal drops

below 1.5 Vdc (0.5% ModBus firing rate) signal.

16. When call for heat is removed, 1

st

stage gas valve

closes and modulating actuator is moved to Park

position, and the inducer is operated for a post purge

period of 60 seconds [PPuurr].

17. Control returns to the standby mode [OOffff].

Ignition and Operational Failures During

a Call for Heat

1. If flame is not detected on the original ignition trial

[AA0011], the controller enters an inter-purge period of 30

seconds [rrEEtt] and then will initiate another ignition trial.

The control will repeat this sequence for up to 4 ignition

trials.

2. If four consecutive failed ignition trials occur, control will

go into lockout [EE0011].

3. If flame is lost during an operating cycle [AA0022], the

controller will operate same as in Step 1.

4. Limited low fire [AA0044] will happen if flame loss at low fire

results in an auto-adjustment that limits the burner turn

down during the rest of the current call for heat.

5. Lockout will also occur for the following:

a. Open Limit or Rollout Switch [EE0022].

b. Low air pressure sensor reading is air pressure

does not correspond to gas pressure [EE0044].

c. No R-W Enable [EE0099].

6. If the combustion air pressure switch opens (blocked

vent or other airflow restriction) during heater operation

with a continued call for heat, the control will lockout for

one hour and then initiate a trial for ignition sequence.

7. Lockout will occur for any lockout error on either control

and terminate heater operation for the duration of the

lockout timing.

8. If no call for heat is present, controller is in the Off

mode [OOFFFF].

Recovery from Lockout (E Code)

1. If the call for heat (thermostat or heat enable closed) is

still present one hour after a lockout occurs, the control

will automatically reset and initiate a call for heat

sequence.

2. Control may also be reset manually by removing power

to the controller for 10 seconds and restoring power to

controller.

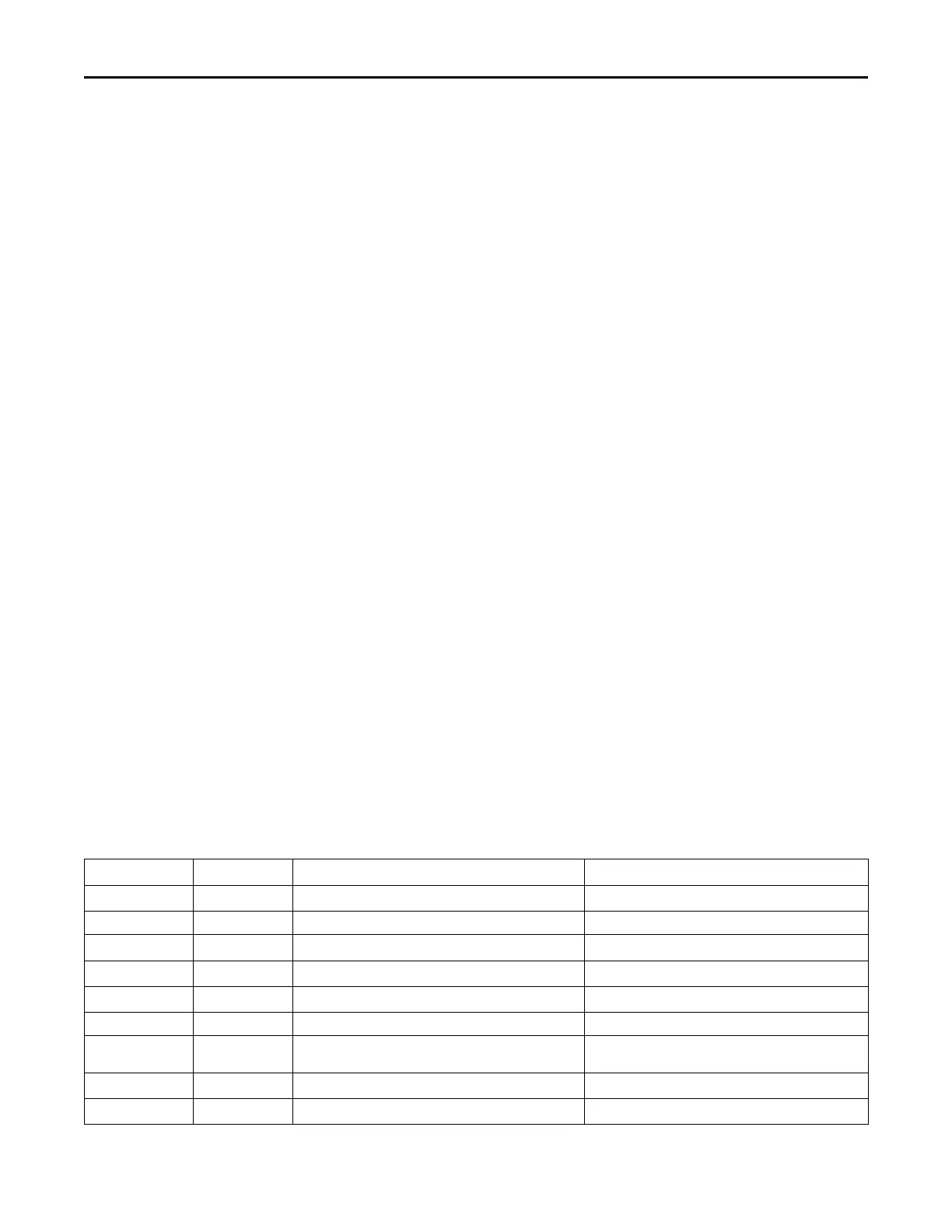

Display Code Code Type Description Additional Comments and Notes

888888 10s L/O Board Failure (Up to 10 seconds at power up) Verify 24 Vac signal input at connector J6.

OOFFFF Status UP Mode: Burner state = Off

PPuurr Status UP Mode: Burner state = Purge

II66nn Status UP Mode: Burner state = Ignition

HHEEAA Status UP Mode: Burner state = Warm up

rruunn Status UP Mode: Burner state = Run

rrEEtt Status UP Mode: Burner state = Retry (with AA0011 or AA0022) Retry delay following either a failed ignition or a flame

loss.

AA0011 Alert Failed ignition attempt

AA0022 Alert Lost Flame Ignition was successful but then flame disappeared.

Unit Start-Up

Loading...

Loading...